A warehouse is a massive structure that is used to keep produced items or raw materials. These produced goods or raw materials are kept in the warehouse until they are transferred for sale. Today we will discuss in great detail the warehouse storage solutions.

Warehouses are often big, simple structures located in industrial parks outside of towns, or villages. Warehouses generally have massive equipment like forklifts, cranes, etc for the transportation of goods.

The role of warehouses changed and specialized during the mid-18th century industrial revolution. The development of warehouses was fueled by the industrial revolution’s vast production of commodities in the 18th and 19th centuries.

At the end of the 19th century, two new sources of power emerged, hydraulics and electricity. The design and usage of warehouses were influenced by these power sources. Technology advancements in the 20th century increased warehouse efficiency.

There are various types of warehouses, for instance, retail warehouses, cold storage warehouses, packing warehouses, etc. Each of these types of warehouses has specific characteristics and is used for specific purposes.

Overall, warehouses are widely popular and are used in almost every country of the world. In this article, everything you need to know about warehouse storage solutions will be discussed. We will discuss the following things in this article:

This article will be especially beneficial for the following group of people:

- Warehouse owners who are looking for warehouse storage solutions.

- Warehouse owners who want to know about different storage solutions for a warehouse.

- Warehouse owners who are looking for the best warehouse storage solution provider companies.

- Warehouse owners who are looking for quality warehouse storage solution providers from China.

- Academicians, researchers, and business who wants to know about warehouse storage solutions.

What Is A Warehouse Storage Solution?

Warehouses are used in many industries, which include,

- Imports.

- Export.

- Manufacture.

- Customs.

- Transport business.

- Wholesale.

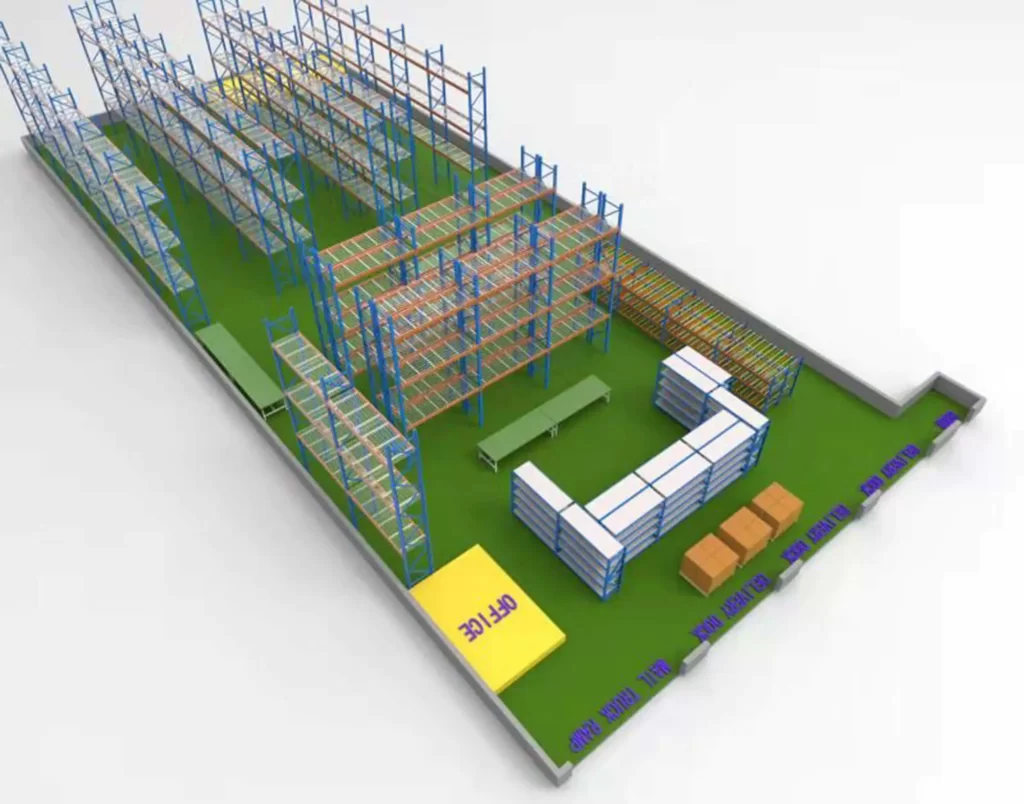

The development of facilities that will increase the existing warehouse’s storage capacity is known as a warehouse storage solution. These structures can be mezzanine floors, pallet racks, wire container, etc.

Warehouses’ main task is to store goods. So, when industries need to increase their storage capacity, they can do the following two things,

- Increase the area of the warehouse.

- Keeping the area the same but increasing the use of available space in the warehouse. Warehouse owners and managers can do so by using the warehouse’s vertical space.

To use the vertical space, they can use storage solutions like pallet racking systems, mezzanine floor systems, etc.

Using an effective warehouse solution ensures you get the best from your available warehouse space. That’s why it’s important to use a warehouse storage solution that can fulfill the storage demand.

What types of warehouse storage solutions are available?

There are various types of warehouse storage solutions are available. Among them, the most used and famous type of warehouse storage solutions is as follows:

- Pallet Racking System.

- Mezzanine Flooring.

- Wire container.

- Hand trolley.

- Roll container.

- ASRS System.

Now, we will discuss each of these warehouse storage solutions.

Pallet Racking System

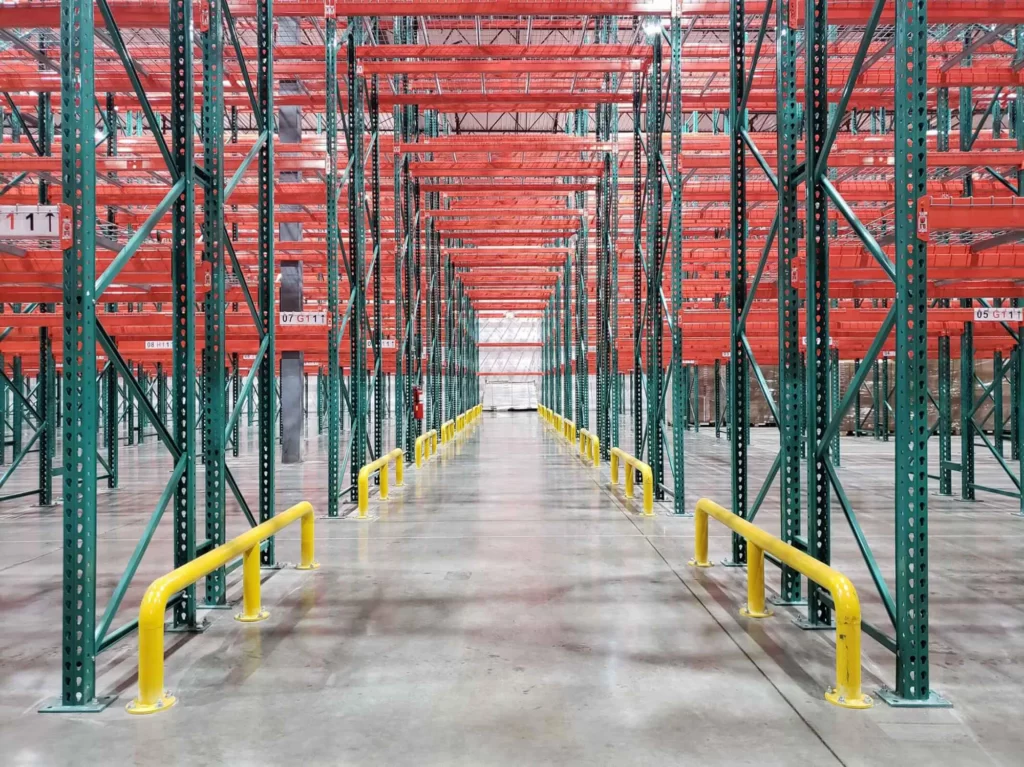

Pallet racks are material handling warehouse aid system that is used to store goods on pallets. The pallet racking system is also a material handling storage aid system. Pallet racking systems can be single or multi-leveled. This system makes it easy to reach stored products.

A pallet rack is manufactured to hold heavy goods. It typically has a load-bearing capacity of 1000 kg to 3000 kg per level. Pallet rack solutions make the most of available space while streamlining inventory needs.

This system is used all over the world as it increases the storage capacity of the warehouse. Pallet rack is also widely known by names such as “Warehouse racks,” and “Pallet shelves”. This system also makes amazing use of the vertical space of the warehouse.

Pallet racks are a crucial part of many warehouse systems. They provide a trustworthy mechanism for locating and classifying products. Pallets are kept in horizontal lines at various levels in a racking system that has been carefully planned out.

There are various parts of a pallet rack, which include,

- Beams.

- Upright.

- Shims.

- Anchor bolts.

- Wire mesh decking.

- Timber decking.

- End-of-Aisle guard.

- Wall ties.

- Guard rails.

- Crossbeam.

- Upright protectors.

Read what is pallet racking to know in great detail about various parts of the pallet racks.

Different Type Of Pallet Racks

Different types of pallet racks are used in a warehouse, which includes,

- Selective Pallet Racking System.

- Double Deep Pallet Racking System.

- Gravity Flow Pallet Racking System.

- Mobile Pallet Racking System.

- Push Back Pallet Racking System.

- Drive-In Pallet Racking System.

- Radio Shuttle Pallet Racking System.

- Narrow Aisle Pallet Racking System.

Each of these pallet racking types has some specific characteristics. For instance, Radio Shuttle Pallet Racking System can operate both in “LIFO” and “FIFO” modes. Using the Narrow Aisle Pallet Racking System ensures you can access all the unit loads directly in the warehouse.

To know in great detail about various types of pallet racks, pallet racking types are highly recommended.

The costs of the different types of pallet racks are also different. For instance, a Selective pallet racking system is one of the cheapest pallet racking systems. The cost of selective pallet racks is $80-150 each.

On the other hand, a mobile pallet racking system is one of the most expensive pallet racking systems. The mobile racking system cost $700-$800 for each pallet. To know about the pallet racking cost, read pallet racking cost.

Advantages Of Pallet Racking System

There are numerous advantages of using a pallet racking system in a warehouse, which include the,

- Pallet racks make great use of the available space in the warehouse. As a result, warehouse owners can keep a lot of goods in a small space using a pallet racking system. You can hold more inventory at once because of this system.

- Compared to other types of warehouse storage solutions, pallet racks are very easy to install. If we compare the installation of pallet racks to mezzanine floors, pallet racks are easy to install in comparison.

- Pallet racking is also very cheap compared to other types of warehouse storage solutions. If we compared pallet racks to mezzanine floors, we will find pallet racks to be very cheap.

- The pallet racking system is very flexible to use. It can be replaced or repaired if it gets damaged.

- Using a pallet racking system increases the efficiency of a warehouse. The workers can work faster when this system is installed in the warehouse.

- A pallet racking system also increases the safety of the goods and the workers of the warehouse.

So, these are some of the amazing advantages of using a pallet racking system in a warehouse environment.

Mezzanine Floor

An elevated floor or platform constructed between the ground and the ceiling is known as a mezzanine floor. Having a mezzanine floor is one of the best warehouse storage solutions you can have in your warehouse.

There are several parts of the mezzanine floors, which include.

- Beams.

- Joists or purlins.

- Elevator

- Columns.

- Decking.

- Alternating tread stairs.

- Stairs.

- Guardrail.

Different Types Of Mezzanine Floors

There are different types of mezzanine floors that are used in the warehouse, which include,

- Structural steel mezzanines.

- Mezzanine racking.

- Cantilever mezzanine.

- Full mat mezzanines.

- Catwalk mezzanines.

- Shelving And Rack-Supported Mezzanines.

- Freestanding Mezzanine Floor.

- Prefabricated Mezzanine Floor.

- Multi-Tier Mezzanine.

To know more about the different types of mezzanine floors that are used in the warehouse, read what is a mezzanine floor. Reading this article will give you an idea of various types of mezzanine floors in the warehouse.

The cost of different types of mezzanine floors is also different. For instance, 500 kg mezzanine racking approximately costs $ (90-110) / sqm. On the other hand, a 500 kg structural steel mezzanine approximately costs $ (80-100) / sqm.

To know about the cost of different types of mezzanine floors, mezzanine floor cost will be helpful.

Advantages Of Mezzanine Floor

Using a mezzanine floor has lots of advantages, which include,

- Installing a mezzanine floor increases the storage capacity of the warehouse. Without expanding the warehouse, installing the mezzanine floor gives you a great opportunity to expand storage.

- Mezzanine floors can be used for various other purposes too in the warehouse besides storing the goods. For instance, it can be used as an observation desk or workspace too.

- Assembling and disassembling the mezzanine floor is comparatively easier than the construction of a new warehouse area.

- A mezzanine floor is one of the safest warehouse storage solutions available in the warehouse. Installing guardrails and handrails on a mezzanine floor ensures the safety of the goods and the workers in the warehouse.

- You can increase the mezzanine floor vertically in the warehouse too. If your warehouse has enough space vertically, you can construct multiple mezzanine floors on top of one another.

- Generally, planning approval is not required before the construction of the mezzanine floor in the warehouse.

To learn more about the advantages and uses of mezzanine floors in great detail, read the uses and benefits of mezzanine storage systems.

A Brief Comparison Of The Mezzanine Floor And Pallet Racking System In The Warehouse

Pallet racking system and mezzanine floors, both of these are incredible warehouse storage solutions. Now, we will give a brief comparison of these two amazing warehouse storage solutions:

Pallet Racking Is Cheaper Warehouse Storage Solutions

We know there are several types of pallet racks and mezzanine floors that can be used in the warehouse. However, in general, the cost of the pallet racks is far cheaper compared to the mezzanine floor.

Mezzanine Floor Is More Durable And Long-Lasting Warehouse Storage Solutions

The durability of mezzanine floors and pallet racks depends on the following things:

- Materials that are used in the construction of pallet racks and mezzanine floors.

- Maintenance of the pallet racks and mezzanine floors in the warehouse.

- Overloading of the mezzanine floors and pallet racks.

- Installation of the mezzanine floors and pallet racks.

Generally, mezzanine floors are more durable than pallet racking systems. This is because warehouse mezzanine floors are made of steel and can hold massive weights. So, the chance of overloading is much less on the mezzanine floors.

The Installation Of Pallet Racks Are Easier

Among these two warehouse storage solutions, the installation of pallet racks is easier. It also costs less time, and equipment compared to the installation process of the mezzanine floors.

Mezzanine Floor Is More Secure As A Warehouse Storage Solution

Compared to the pallet racking system, mezzanine floors are a more secure warehouse storage solution. If the mezzanine floor is installed properly, there is very little chance that it will break down.

Installing guardrails and handrails in mezzanine floors ensures that goods and workers remain safe in the warehouse.

The pallet racking is safe too, but there remains a chance of breaking the pallet racks due to overloading. Mezzanine floors can withstand a lot of weight compared to pallet racks. That’s why mezzanine floors are a more secure warehouse storage solution.

Wire Container

A wire container is a type of collapsible storage container that is used in the warehouse to transport turnover goods. It’s safe to keep the tools, parts, or products secure using the wire container as a warehouse storage solution.

The basic structure of the wire container is constructed with solid steel wire. U-shaped channel steel welded at the bottom of the wire container.

These wire containers are very flexible and durable. The good part is these can be easily modified or customized based on your need and facility. Wire containers are commonly used in three-dimensional warehouse facilities, logistics distribution centers, or industrial workshops.

Benefits

Wire containers can be folded if they are not in use. The surface of the cages is galvanized and anti-oxidant.

It can be used for a long time with zero to low maintenance. The loading capacity of these cages is great and they can be used for multiple purposes in the warehouse. A wire container is a great option if you want to increase the efficiency and storage capacity.

How Wire Container Works

A good storage system provides an organized and maximum usage of space. The wire container offers you more inventory control, better mobility, and handling of your products. They can be used to store products of the same specs, fixed capacity, or clear out storage.

The cages also offer great adaptability as they can be easily stacked with low maintenance. wire containers are mainly used for vulnerable or delicate items as they offer great security features.

So, to have improved organization and control over product distribution and optimization of space, wire containers are the answer.

Hand trolley

A hand trolley is a piece of equipment that is used to transport any goods within the warehouse. This is a material handling equipment that made the physical working in a warehouse easy and flexible for the workers.

Hand trolleys are also known as hand trucks. It is widely used by workers to move or stock heavy products from one place to another.

Basically, a hand trolley is a two-wheeler constructed in an L shape and operated by hands. Two small wheels are located underneath the load-bearing point. Moreover, two handles are in the support frame. These handles are for pushing or maneuvering the trolley in different directions.

Benefits

Hand trolleys can protect the workers from any back or bodily injuries which can occur from lifting heavy tools. It also increases the efficiency and flexibility of a warehouse facility.

It also increases the worker’s ability to load or transport goods which enhances the time efficiency in progress. Hand trolley reduces operational cost too.

How Hand Trolley Works

It mainly works as a maneuvering device in a warehouse which offers great resilience in the product storage system. When there is a need to move any heavy object, a hand trolley can be used for that.

When the trolley is empty it will stand in the L shape. Once the products are stacked in the load platform the trolley will tilt backward automatically. Now, all you have to do is push the trolley using the handles located in the support frame. As the load platform will face upwards against the floor, moving the trolley will become easy.

Roll containers

Roll containers are an excellent choice for moving heavy and voluminous products in the warehouse. The growth of logistics is bringing more developed material-handling equipment like roll containers into the industry.

The roll container is generally made of solid steel wire and has a base mesh with removable sides. The front wall can be mounted thanks to the self-hooking system. It is designed in a way that reduces the risk of any accidents during transportation.

Benefits

Roll containers have made warehouse operations more efficient and quicker. It is very easy to handle as it requires only one person for the job to cover.

The best advantage of using this equipment is it provides great security for all the items kept inside of it. If you are searching for a cost-efficient and eco-friendly storage solution for your warehouse, it’s a perfect choice. Due to the adaptability of these devices, they can be a good choice for different applications.

How Roll Container Works

Roll containers are widely used in the manufacturing industry and other warehouse operations. These containers are very tough and lightweight, making them easy to maneuver and store. It can be easily folded if there is no use for it.

All you have to do is put the items or products in the load chamber, then push the container. It has four small wheels mounted in each corner of the device, making it very easy to move.

ASRS System

The ASRS system stands for “Automated Storage and Retrieval System.” This system is very expensive. If any warehouse has a good budget, only then they should go for the ASRS system.

The “Automated Storage and Retrieval System” cost $80-$120 for each pallet.

Benefits

There are multiple benefits of using the ASRS system in the warehouse facility. This system works with amazing accuracy and precision. Even using this method increases the accuracy of the storage system by more than 90%.

Also, this system is an automated system. So, the management of things becomes much easier if this system is used. This system enhances ergonomics too by giving the employee goods at a comfortable height. When the space of the warehouse is limited, this system is very effective.

How ASRS Works

ASRS system consists of many computer-controlled devices. From predetermined storage spaces, these computer-controlled devices automatically can insert and remove loads.

This system has a high rack height and is generally more than 10 meters. The storage density in the ASRS system is extremely high.

What Is The Most Widely Used Warehouse Storage Solution?

The two most famous types of warehouse storage solutions are pallet racking and mezzanine floors. Besides these two types of warehouse storage solutions, there are other types of warehouse storage solutions, which include,

- Wire container.

- Roll container.

Among these warehouse storage solutions, pallet racking is the most widely used warehouse storage solution. After World War II, pallet racks become widely popular as warehouse storage solutions.

There are various reasons that contribute to the popularity of pallet racks as the most used warehouse storage solutions. These reasons are as follows:

Pallet Racking Is One Of The Cheapest Warehouse Storage Solutions

The pallet racking system is incredibly cheaper compared to some other types of warehouse storage solutions. For instance, if we compared pallet racks to the mezzanine floors, we will find that it is incredibly cheaper.

You can get a selective pallet rack for $46-60 each. So, if a warehouse owner were to use pallet racks; he doesn’t have to invest too much money. Using pallet racks gives him the advantage to become more profitable by cutting down business costs.

The cheaper cost of the pallet rack is one of the main reasons behind its popularity.

Pallet Racks Can Be Easily Repaired

Due to various reasons, some parts of the pallet racks may get damaged. If a pallet rack gets damaged, it is easily repairable. Due to its wide use across the globe, spare parts are also available.

The pallet Racking System Is Very Easy To Install And Use

The pallet Racking system is very easy to install and use. Especially if we talk about the installation process, it is a lot easier compared to the mezzanine floors. Using pallet racks and storing goods on them is also a very easy task to do.

Pallet Racks Are Easily Transportable

Due to various reasons, a warehouse may have to shift its location. At the time of shifting the warehouse from one place to another, pallet racks are easily transportable. The ease of transportation is another reason behind the popularity of pallet racks.

So, these are some of the reasons why pallet racks are the most used warehouse storage solution.

How Can I Choose An Effective Storage Solution For My Warehouse?

As we have discussed earlier, there are various types of warehouse storage solutions. All warehouse storage solutions have particular advantages and benefits. So, how would you know which one is the best warehouse storage solution for your warehouse?

To find out this answer, we will discuss how can you find the most effective warehouse storage solution:

1. Identify Your Product Type

First, identify what type of product you want to store in your warehouse storage. For instance, if you are storing food and beverage products in your warehouse, pallet racks are ideal for you.

Among different types of pallet racks, the Drive-In Pallet Racking System is used in the food and beverage industries.

Products like fruit and milk have a short shelf life. When the products have a short shelf life, they need to be stored in cold storage. A mobile pallet racking system can be used to store cold products.

If your products have a high turnover efficiency then you need to use a FIFO racking system. “FIFO” racking system means, “First In, First Out” Racking system. “Radio Shuttle Pallet Racking System” and “Gravity Flow Pallet Racking System” can operate in FIFO mode.

2. Clarify The Size Of The Warehouse And Supporting Equipment

You need to find out the exact dimension, (length, width, and height) of your warehouse. Because it is extremely important to choose the best warehouse storage solution for you.

For instance, in very small warehouses, mezzanine floors are not suitable. Because mezzanine floors take up a sizeable amount of ground space in the warehouse.

You also need to know the dimension for other reasons too. For instance, the recommended minimum height for the mezzanine floor construction should be 7 feet or 2.1336 meters. According to the “Internation Build Code- 2021, Section 505.2;”

“A mezzanine or mezzanines in compliance with Section 505.2 shall be considered a portion of the story below. Such mezzanines shall not contribute to either the building area or number of stories as regulated by section 503.1.”

“The area of the mezzanine shall be included in determining the fire area. The clear height above and below the mezzanine floor construction shall be not less than 7 feet.”

Suppose your warehouse’s total height is 15 meters. So, if you know this height, then you can build multiple mezzanine floors on top of one another. Building multiple mezzanine floors on top of one another will make the best use of vertical space.

Another thing to look for is the supporting equipment that you are using in the warehouse. For instance, if you are already using a forklift, then pallet racks are an ideal choice for you.

3. What Is Your Budget

Budget is another important thing when considering the ideal warehouse storage solutions. If you have a lower budget, you should go for a cheap pallet racking system.

Double Deep Pallet Racking Systems, Selective Pallet Racking Systems, etc can be ideal storage solutions for a cheaper budget.

When your budget is high, you should go for expensive warehouse storage solutions. An expensive warehouse storage solution helps you in many ways.

For instance, if you choose a mobile pallet racking system, it will help you to automate your warehouse system. In the long run, automation of your warehouse will help you to-

- Decrease the cost of employing workers as many things can be automated.

- Increase efficiency in the warehouse.

If you have a good budget for warehouse storage solutions, consider installing mezzanine floors. Installing multiple mezzanine floors on top of one another ensures that you make the best use of vertical space.

So, if you have a clear idea about your budget, you can plan accordingly for warehouse storage solutions.

4. Find The Right Warehouse Storage Solution Provider

After you have chosen the most effective warehouse storage solution, now the question comes where to buy it from? Warehouse storage solutions like mezzanine floors or pallet racks can’t be bought from shops instantly.

You will have to order customized warehouse storage solutions from the manufacturer company. While buying a warehouse storage solution, make sure the company provides the following things:

High-Quality Materials

First, find out what kind of material is it using to construct your warehouse storage solution. For instance, a manufacturing company is using steel to construct mezzanine floors. Before ordering from them, make sure they are using high-quality steel to construct mezzanine floors.

Using high-quality materials to construct mezzanine floors ensures it is durable and last longer.

Experience Warehouse Storage Solution Manufacturing Company

Make sure the warehouse manufacturing company is experienced in the construction of warehouse storage solutions. An experienced company will give you a better product compared to an inexperienced company.

Constructing mezzanine floors or pallet rack is a sophisticated task. It needs a lot of calculation to construct these things. Experienced engineers, and workers who are experts in the construction of pallet racks or mezzanine floors.

Also, an experienced company can help you with things like drawings, and installation of the warehouse storage solution.

Make Sure The Company Provides After Sales Service And Installation Service Too

An ideal warehouse storage solution manufacturing company should provide installation service too. Warehouse storage solutions like Mezzanine floors and pallet racks both require installation.

If you chose a company that offers installation service, you may have to separately pay for it. That will increase the overall cost. That’s why it’s best to choose a rack manufacturing company that offers installation service too.

Another thing you should look for is if the company provides after-sales service. After the construction of pallet racks or mezzanine floors, any problem can occur for various reasons. That’s why chose a manufacturing company that provides after-sales services

Find The Company That Offers A Cheaper Price

Why pay extra money when you can have the product at a cheaper price? Always try to cut down the cost of your business even if it’s a very small cost. You should choose a warehouse storage solution provider that offers high-quality products and services at lower costs.

One thing you can do is buy from a company that manufactures pallet racks from China. Because the production costs and the wage of the worker are much lower in China. That’s why Chinese companies in general can provide high-quality products at lower costs.

If you are looking for a company that fulfills all these criteria, Mracking is the ideal choice. Mracking fulfills all the above mentioned criteria which makes it an ideal choice. contact Mracking to get an idea about the price of your warehouse storage solutions.

Top 10 Warehouse Storage Solution Providers.

There are so many warehouse storage solution providers around the world. Now we will discuss the top 10 warehouse storage solution providers:

1. Mracking

The factory of Mracking is located in Guangdong, China. Mracking’s engineers are among the most inventive in the pallet racking industry. Mracking can offer CAD drawings and 3D drawings for warehouse storage solutions.

Mracking offers various types of pallet racks and mezzanine floors, which includes,

- Selective pallet rack.

- Teardrop pallet rack.

- Cantilever rack.

- Mold rack.

- Shuttle rack.

- Structural steel mezzanine.

- Mezzanine racking.

Besides the mezzanine floor and pallet rack, they offer other logistic equipment too, which includes,

Moreover, they offer a 20-year warranty service! If anything happens to the product they have provided within this timeline, they offer free repair or replacement.[Provided that it is not the result of human factors]

Mracking also offers installation service along with their pallet racks or mezzanine floor. Their customer service remains open 24/7/365! The delivery time of Mracking is 15 days in general. Mracking gives warm welcome if anyone wants to visit their factory in Guangdong, China.

The product Mracking offers are of very high quality. The price is also much cheaper compared to many other warehouse storage solution providers. So, don’t be late. Order your desired warehouse storage solution from Mracking!

2. Steelking

Steelking is a well-known manufacturer and premier supplier of pallet racking in the USA. The steelking offers highly engineered pallet racks that can withstand high damage and abuse. Moreover, the pallet racks come off with an impact-resistant and powder-coat finish.

Steelking provides dynamic rack options for pallet racking which includes drive-in/drive-through racking, pushback rack, pallet flow rack, and many more. Adding more to that, keeping load factors and seismic zones in mind, they offer you a layout drawing and installation service.

Steelking has different types of pallet racks in their product line, which include

- SK2000 Boltless tubular pallet rack.

- SK2500 Pallet racks- Bolted Closed tube.

- SK 3000 structural racks.

- SK4000 Tubular structural rack.

- Double-deep rack system.

Steelking guarantees low-risk pallet racks and less downtime and maintenance costs.

3. Mecalux

Mecalux, is a leading manufacturer of automated warehouse, metal rackings, and storage system solutions located in Spain. Mecalux is widely recognized for the application of the most advanced technology in the automated warehouse industry.

Mecalux offers pallet racking services following two different methods. If you want to maximize the storage space of your warehouse, Mecalux is the answer to your call.

Mecalux also offers mezzanine floors to double up the space using the height advantage of your warehouse. They offer free installation for the mezzanine floor as well.Mecalux provides several types of pallet racking-

- Conventional pallet racking.

- Drive-in pallet racking.

- live pallet racking.

- Mobile pallet racking.

- Shuttle racking.

- Clad- rack warehouse.

- Push-back pallet racking.

4. Dexion

Dexion is a leading manufacturer of warehouse logistics and provides unique storage solutions for your warehouse. Dexion was the first-ever manufacturer that introduced adjustable storage to the world.

Dexion offers various types of pallet racks with a dynamic storage solution with integrated conveyor modules.

Dexion constructs highly-engineered mezzanine floors with a reduced risk that creates extra space in your warehouse building.

Dexion manufactures various types of pallet racking, which include:

- Pallet flow racking.

- Drive-in pallet racking.

- Speedlock P90+ pallet racking.

- Anti-collapse mesh.

- Standard wide aisle pallet racking.

5. Uline

Uline is one of the leading manufacturers and distributors of industrial logistics and packaging materials in North America. They are providing high quality with the best value for over 40 years.

Uline constructs various types of pallet racks including CAD and 3D-printed pallet racks. Uline is having a good run on the market in terms of cost efficiency and high-valued industrial logistics products.

Uline also offers the construction and installation of mezzanine floors including the safety switch gates. Types of pallet racking services Uline provides are as follows-

- 24” Deep pallet racks.

- Pallet racks enclosure.

- Portable pallet racks.

- Nettings for pallet racks.

- End rack protectors.

- Jumbo pallet rack bins.

- Pallet shuttles.

6. APEX

Apex is a company that provides warehouse logistics solutions and automatic warehouse storage systems. It also offers full-service material handling that can boost warehouse space and productivity.

The designers and the engineers of the APEX warehouse are very experts in implementing the latest processing and technologies. APEX is well-known for constructing CAD drawings and 3D-printed pallet racks for warehouses.

7. Storage Solutions

The storage solution is a quite known face in the automatic storage solution sector. They offer warehouse logistics design and installation at a very affordable cost.

Storage solution has been a unique provider of their data-driven warehouse automation solution. Their data-driven warehouse automation solution can boost the productivity and in-house space of the warehouse facility.

The automatic pallet rack handling system of storage solution creates a less-labor process. As a result, it decreases the chances of risk of injuries and strains.

From a simple pallet rack to a complex pallet handling process, storage solution provides construction and installation of all.

8. Macrak

MACRAK is a recognized company that serves the material handling industry. MACRAK largely provides pallet rack repair kits and racking column protection products and services.

MACRAK offers multiple engineered frame repair solutions and reinforcement options for specific needs. MACRAK performs a specialized installation program that greatly reduces the risk and customer cost.

MACRAK offers different types of pallet rack repair solutions, those include-

- Engineered rack repair to ANSI standards.

- Pallet rack repair kits for all brands.

- Rack repair turnkey service.

MACRAK also has a·huge selection of warehouse rack repair kits

9. SSI SCHAEFER

SSI SCHAEFER is a storage and shelving solutions company that offers automated material handling applications. This automated material handling application includes warehouse management systems and ASRS.

From customized shelving to manual or partially or fully automated shelving, SSI SCHAEFER provides all of them.

SSI SCHAEFER provides effective solutions and advice for customized pallet racking systems and single and multi-storage pallet designs. Other pallet racks SSI SCHAEFER offers are as follows:

- Mobile pallet racks.

- Pallet dynamic flow rack.

- Pallet shuttle.

- Drive-in pallet racking.

- Push-back pallet racking.

10. Unarco

Unarco is famous and the oldest warehouse logistic and automatic storage manufacturing company in the USA. They are the largest suppliers of pallet racks offering several types of racks with efficient storage solutions.

Unarco offers more options in terms of pallet racks compared to its competitors. From simple pallet racks to T-bolt pallet racks, they have everything covered.

Unarco offers specially engineered mezzanine floors that give additional space for your facility. They also offer an installation program for mezzanine floors.

This is everything you need to know about warehouse storage solutions. Let us know if you have any queries about warehouse storage solutions. Contact Mracking to get high-quality warehouse storage solutions for your warehouse.