In the modern warehouse industry, pallet racks are the most popular warehouse storage solutions. Today we will discuss in detail “The most complete list of warehouse pallet racking parts.”

If we talk about the pallet racks, it is incredibly cheaper compared to other warehouse storage solutions like Mezzanine floors. Apart from being cheap, pallet racks have a lot of advantages that make them the most popular warehouse storage solution.

Among the reason pallet racks are so prevalent in a warehouse environment is the availability of pallet racking parts. If any pallet racking parts get damaged, they can be easily replaced.

There are different types of pallet racks in the warehouse. For instance, selective pallet racks, mobile pallet racks, drive-in pallet racks, etc. Each of these pallet racking types has a different design.

Warehouse racking parts should be well maintained and taken care of. The more you take care of pallet racking parts, the better the chance of lasting longer. For instance, a beam is an important warehouse racking part.

To take care of the beam properly, you should not overload it. Overloading the pallet racks will make the beam of the pallet racks weaker. Overloading may also cause the beam to be damaged.

In this article, we will discuss the following things:

This article will be especially beneficial for the following group of people:

- Warehouse owners and managers who want to know about the most common pallet racking parts.

- Warehouse owners who are looking for a reliable company to buy their warehouse racking parts.

- Academicians and researchers and people who want to know about pallet racking parts names.

Most Common Pallet Racking Parts Names.

Pallet rack allows easy access to the goods you have stored in your warehouse and helps you keep track of what’s where. In this article, we’ll look at the most common pallet racking parts.

Pallet rack parts are the many sections that make up the racking’s structure. Additionally, it guarantees that the loads it supports are stored correctly. The most common pallet racking part names are:

- Pallet Racking Boards

- Pallet Racking Divider

- Support Beams

- Shims

- Baseplates

- Pallet Racking Upright

- Pallet Racking Beams

- Aisles

- Pallet Racking Upright Protector

- Row Spacer

- Diagonal struts

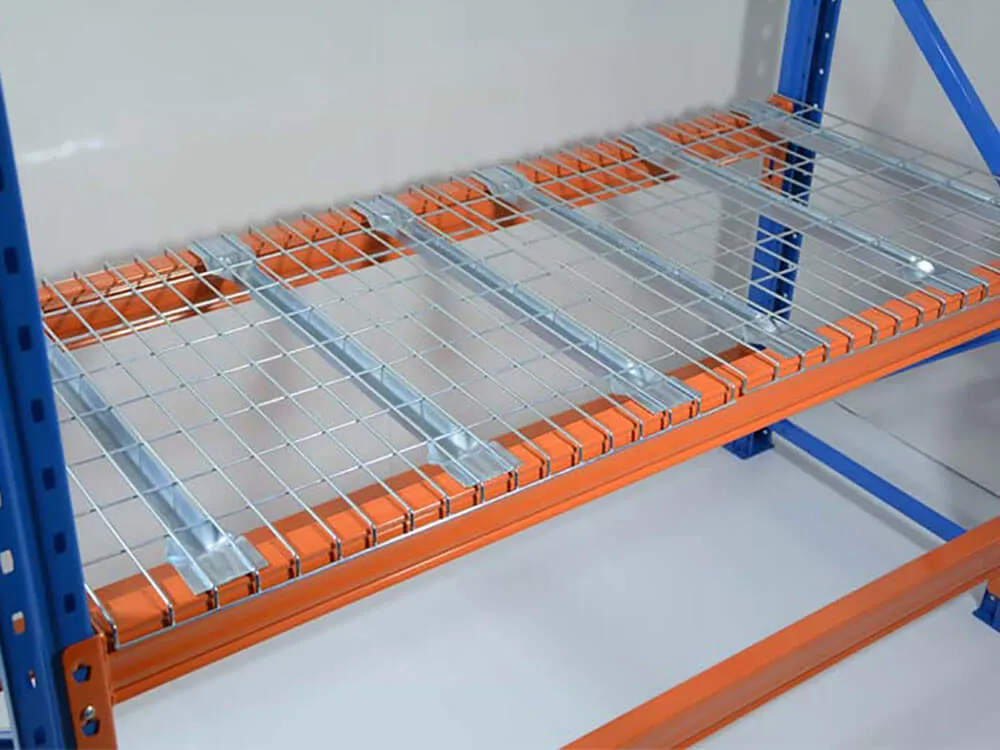

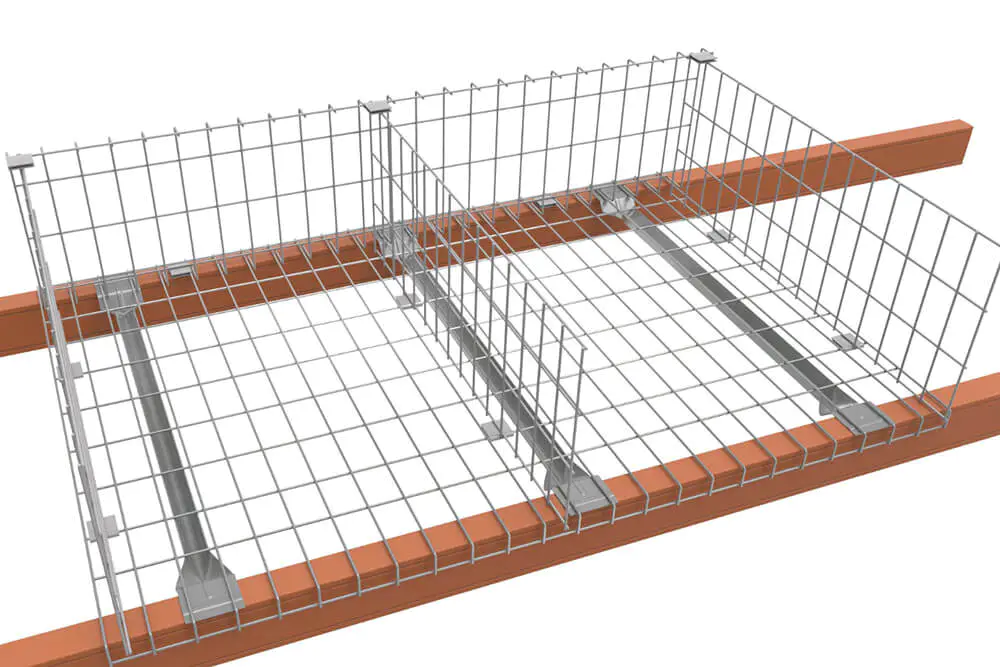

Pallet Racking Boards

There are usually three types of pallet racking boards, which are plywood decking, wire mesh decking, and steel plate decking. Using pallet racking boards can effectively reduce the number of items falling from high places and make your warehouse storage work more safely. If you need to know the difference between various pallet racking boards and their advantages and disadvantages, please read “Pallet Racking Boards“.

Pallet Racking Dividers

Pallet rack dividers are a great way to organize large quantities of goods. They’re beneficial for warehouses that need to keep their goods organized and easy to find. There are many types of pallet racking dividers.

Standard Self-Locking Pallet Rack Divider

The typical self-locking pallet rack divider is a straightforward object with a slot. The operator puts one end of the item they want to store into the slot and then closes it. This makes it possible to secure and organize things on pallets.

Self-locking pallet racking dividers make storage easy because they don’t require any special tools. They can only be used with certain types of items, such as boxes or cases; they cannot be used on uneven surfaces.

Wire Dividers

Wire dividers are the most common type of pallet racking dividers. Wire dividers come in different sizes and shapes. They can be used on any kind of pallet rack.

Riveted Hooks

Riveted hooks are similar to inverted hooks, but they use rivets instead of wires to attach them to the edge of a rack. This makes them stronger than inverted hooks. Riveted hooks are generally more expensive than wire or hooked versions.

Support Beams

The support beam spans across the rack beam, further enhancing the stability of the rack. Usually, each layer is equipped with five support beams, often used in conjunction with the plywood, which can improve the bearing capacity of the plywood.

Shims

Shims adjust the height of pallet racks and make them more stable. Shims are made from various materials and can be used in many different ways. They are often made from wood or metal. Shims may also be made of plastic or rubber.

Baseplates

Baseplates are the foundation of a pallet rack. They are available in a variety of materials and sizes and can be used to anchor shelves, storage bins, and other accessories. Seismic forces and the weights applied to the pallet rack are used to determine the baseplate’s size.

Pallet Racking Upright

Pallet racking upright are metal components that make up the racking frame’s vertical framework. Without them, the racks will become unstable and fall over. Upright are also a cost-effective way of providing extra storage space in your warehouse.

Size

You should choose a large size to hold at least four times the weight of each pallet without any wobble or movement. Larger upright can be used to hold up more than four times their weight.

Material

Steel is the most popular type of material used for these uprights since it is strong but lightweight enough to avoid deterioration or rusting over time.

Shape

Upright shapes, such as round poles or square tubes, tend to provide more stability than those with sharp edges, such as square tubes.

Pallet Racking Beams

The pallets are supported by horizontal pallet racking beams that are inserted into holes in the upright. They are made from high-quality materials, such as steel and stainless steel, and are usually coated with a protective coating to prevent rusting.

Aisle

Pallet rack aisles are often used in warehouses. The setup of these aisles should be done with careful consideration to ensure that they can store the maximum amount of product.

Many different aspects need to be looked at when designing these aisles. For these aisles, width and height, material, spacing, and design must be considered.

It is also essential to make sure that there is enough space between each aisle. So people don’t feel congested while trying to walk down them or move equipment around in them.

Pallet rack aisles help increase workplace productivity by providing easy access to products.

Pallet Racking Upright Protectors

The pallet racking upright protector is a great way to protect your pallet racking. It can be easily installed on your pallet rack and will keep your shelves safe from the elements. They are sometimes referred to as rack shields or guards.

There are other benefits to using a pallet rack upright protector as well. For one, they are made of durable plastic that is easy to clean and maintain. Pallet rack upright protectors are an affordable means for ensuring the safety of your goods in the warehouse.

Row Spacer

The row spacers improve the safety of the racking system by connecting two sets of adjacent pallet racks.

Selective pallet racking without row spacers can often lead to aisles that are too wide and prevent you from storing as much as you can with a more compact system.

Diagonal Struts

Selective pallet racking Diagonal struts are an important part of a racking system. They provide lateral stability and prevent the system from toppling over. Diagonal struts also help to redistribute weight and prevent sagging.

These are some of the most common pallet racking parts names. With the advancement of this article, we will further discuss other special warehouse pallet racking parts names.

Parts For Other Types Of Warehouse Racks.

There are many different types of pallet racking available on the market, each with its own set of benefits and drawbacks. In the following article, we will take a look at some of the most popular parts of pallet racking to help you choose the right pallet racking system for your warehouse.

The other pallet racking types that we will discuss here are as follows:

Drive-In Pallet Racking Parts

There are a few essential parts to any drive-in pallet racking system. The main component is the rack itself. It is comprised of uprights, beams, and load levels, which ensure the stability and function of the rack.

The uprights are the vertical supports that hold the system up. The beams are the horizontal support members that connect the uprights and provide a surface for the pallets to rest on. The load levels are the individual shelves within the system holding the pallets.

Other Drive-In Pallet Rack Components

There are some parts in Drive-In pallet racking other than the common parts. These parts include:

- Interior Support Arms

- Rail Support Beams

- Drive-In Rail

- Overhead Tie Beams

- Top X-Bracing

- Rear X-Bracing

Interior Support Arms

The drive-in pallet interior support arms are used to support the pallet interior from the floor up. The arms are adjustable in length to accommodate different pallet sizes. They can be locked in place to provide stability.

Rail Support Beams

Rail support beam that is placed underneath the drive-in pallet rails. It provides extra support to the rails so that they can better withstand the weight of the pallets. This beam is made out of steel and is very durable.

Drive-In Rail

The drive-in rail is made of structural steel angles and spans the length of the system. This allows a continuous seat for the pallets to be put on and stored. It is attached to the support arms and beams. Drive-in rails may come in two parts for longer systems.

Overhead Tie Beams

Overhead tie beams are an important part of drive-in pallet racking systems. They provide structural support for the racks and help keep the system stable. Tie beams also help prevent the racks from toppling over when loaded with heavy items.

Top X-Bracing

The purpose of the top X-bracing is to provide additional support and stability to the racks, which can help prevent them from tipping over or collapsing.

Rear X-Bracing

Rear x bracing is a key component of drive-in pallet racking systems. It provides stability and support to the rack, preventing it from tipping over or collapsing. Rear x bracing also helps to distribute weight evenly.

Shuttle Pallet Racking Parts

There are a number of different parts that make up a Shuttle Pallet racking system, and it is important to be familiar with these parts to properly maintain the system.

The main Shuttle Pallet Racking parts are:

- Bracing

- Support Beam

- Upright Protector

- Wheel Stop

- Wire-mesh

- Pallet Backstop

Pallet Backstop

The shuttle pallet racking backstop is a device that prevents the shuttle from moving backward. It is placed at the rack system’s end and typically made of metal.

Wheel Stop

For your warehouse to be safe and secure, you must have pallet racks with wheel stops. The wheel stops can help prevent accidents by preventing pallets from rolling too far and causing damage or injury.

Gravity Flow Pallet Racking Parts

Gravity-flow pallet racks are designed for high-density storage and are suitable for warehouses with high inventory turnover rates. They are usually configured with a single deep lane of pallet racks; This allows the pallets to move by gravity from the loading area to the unloading area.

The parts of a gravity flow pallet rack include the following:

- Pallet rails

- Rollers

- Incline

- Stop

- Brake

- Guard Rail

- Control Panel

- Beams

Pallet Rails

Pallet rails are the main vertical beams that support the pallets and provide the structure of the rack.

Rollers

The rollers are installed on the racking frames and are designed to roll easily when a pallet is placed on them. They allow for easy access to the goods stored on the racks and allow for quick and efficient loading and unloading of the goods.

Incline

The incline is the angle of the railings, which allows for the pallets to roll down the railings.

Stop

The stop is placed at the end of the incline to prevent the pallets from rolling off the rails.

Brakes

Brakes act as a cushion to slow the pallets as they move down the aisle on the rollers. This helps to ensure that the pallets do not crash into one another and that they can be safely loaded and unloaded.

Guard Rails

Guard rails are placed along the sides of the incline to protect the pallets from falling off the sides of the railings.

Control Panel

A gravity flow pallet racking control panel is a device that allows for the remote control of a gravity flow pallet racking system. It includes a display and buttons that allow the user to set the desired speed, flow rate, and direction of the pallet racks.

How to Install Gravity Flow Pallet Racking?

We have discussed various pallet racking parts, a question may come to your mind how can these parts be assembled? To simplify the assembling process for you, we will briefly describe the installation process of pallet racking parts.

The following is a guide on how to install gravity flow pallet racks:

- Begin by assembling the pallet rack frames. Use a level to ensure the frames are even and secure them to the floor using appropriate anchor bolts.

- Install the horizontal beams. Use the appropriate bolts and nuts to secure the beams in place.

- Install the vertical posts. Again, use the appropriate bolts and nuts to secure the posts in place. Make sure that the posts are level and secure.

- Install the decking. Place the decking into the frames and secure it with the appropriate bolts and nuts. Make sure that the decking is level and secure.

- Install the safety clips. Place the safety clips into the posts and secure them with the appropriate bolts and nuts.

- Place the pallets onto the decking. Make sure that the pallets are properly secured and stable.

- Place the safety barriers. Place the safety barriers around the edges of the pallet rack and secure them with the appropriate bolts and nuts.

- Install the labels. Place the labels onto the pallet rack to identify the contents.

- Test the rack. Ensure that all the components are properly secured and the rack stable.

The pallet racking installation guide will be beneficial to know more about the installation of pallet racks.

Push Back Pallet Racking Parts

An accumulated-pallet-based racking system is referred to as a push-back racking system. Pallets of materials can be kept on either side or side of a retail aisle.

Push-back pallet racking parts typically include a base frame, horizontal beams, rails, trolleys, carts, roller beds, pallet backstops, pallet guides or grips.

Pallet Guides or Grips

Push-back pallet racking guides or grips are components of a push-back pallet rack system. They are designed to hold the pallet in place. This ensures that the pallet does not move when goods are added to or removed from the rack.

Trolleys/Carts, or Roller Beds

Push-back pallet racking, trolleys, carts, and roller beds are used to transport goods within warehouses and other areas of storage.

The trolleys and carts are mounted on a rail system and can be used to move pallets of goods or individual items. The roller beds are used to move containers or boxes of goods around the warehouse.

So, these are parts for other types of warehouse racks.

Mracking Offers Various Types Of Pallet Racking Parts.

Mracking is one of the top manufacturing and trading companies for storage racks. It has been in China for more than 16 years. Mracking is concerned with protecting the environment and workplace safety during production.

Mracking has received certification for its environmental management system, health and safety program.

If you are buying pallet racking parts like beams, posts, baseplates, and shims, Mracking can provide you with these pallet racking parts.

Mracking doesn’t produce all of the pallet racking parts. However, We know that buying pallet racking parts from different places is difficult. For instance, if you buy pallet racking parts from different places, the quality of these parts may not be the same.

Apart from that, the shipping cost may increase if you buy pallet racking parts from different places.

So, to ease your problem, Mracking offers one-stop solution for all pallet racking parts you need. However, there are a few components that we cannot produce ourselves.

We provide a one-stop shop for all pallet rack parts to help our customers shorten the procurement process and save time.

As said earlier, we produce many pallet racking parts in our factory. However, for the pallet-racking parts we supply to our consumers, we ensure their quality.

Thanks to our nearly two decades of experience in the warehousing industry, we source a wide variety of pallet rack parts for our customers. Therefore, even if some of the pallet rack parts we supply are not manufactured by us, we choose to cooperate with stable pallet rack parts suppliers that we have worked with to ensure the quality of pallet racking part products.

So, this is our discussion of “The most complete list of warehouse pallet racking parts.” Please let us know which pallet rack part you are interested in.