Having a mezzanine floor is a great way to increase the storage space of a warehouse. Mezzanine floors can also be used as a workspace or observation desk in the warehouse. Today we will discuss how to build a mezzanine floor for the warehouse.

Between the ground and the ceiling of the warehouse, a warehouse mezzanine floor is installed. There can be multiple mezzanine floors on top of one another in a warehouse. Stairs are needed to go to the mezzanine floors.

Many warehouses around the world use the mezzanine floor to increase storage space of their warehouse. When a mezzanine floor is built, the place below it and over it is accessible too.

In our today’s article, we will discuss the following things:

This article will be especially beneficial for the following group of people:

- Warehouse owners and managers who want to know about the building process of a mezzanine floor.

- Warehouse owners and managers who want to hire a reliable mezzanine floor installation company.

- The warehouse manager wants to find out if his mezzanine floor installation was done properly or not.

- Academicians and researchers who want to know about the mezzanine floor building process.

Equipment That Is Needed To Build The Mezzanine Floors.

There is much equipment that is needed while constructing the mezzanine floor. Some of the important tools and machines that are needed to build the mezzanine floors are as follows:

Measuring Tape

The measuring tape is a must-have piece of equipment while installing the mezzanine floor. You will need it in many places in building the mezzanine floor, which includes,

- To have an accurate measure of the area you want to build the mezzanine floor.

- To get a precise distance from columns to columns of the mezzanine floor.

- To get accurate measures of the steps of the stairs of the mezzanine floor.

A measuring tape is needed to ensure you have constructed the mezzanine floor according to the plan. A measuring tape is a very cheap tool compared to other expensive handling equipment like forklifts.

From the workers to the engineers, everyone should use a measuring tape to ensure the accuracy of the calculation.

Forklifts

While installing a mezzanine floor, forklifts are used for the following purposes:

- Lifting heavy objects.

- Lifting mezzanine structures.

Ladder

Ladders are essential equipment that is needed to construct the warehouse mezzanine floor. While building a mezzanine floor, you need to work on different heights to install mezzanine floors.

It is recommended to have multiple ladders of different sizes while constructing the mezzanine floor.

Drill Machine

While building a mezzanine floor, you need to make holes in various parts of the structure, which include,

- Floors.

- Walls.

Bi-Energy Scissor Lift

This machine has a broad deck and massive lift capabilities. That’s why these machines can be used in the building of the mezzanine floor. The operation of this scissor lift is comparable to that of an electric machine.

This qualifies it for use indoors where limited fuel emissions are necessary. This machine’s Fuel option charges the battery. As a result, it can be used for more work even when there is no electricity.

Safety Glasses

Like other construction activities, building a mezzanine also creates a lot of dust. To protect eyes from dust and other harmful elements, safety glasses should be used.

Wide Deck Scissor Lifts

Electric-powered wide deck scissor lifts have the following capabilities:

- Rought terrain tires.

- Outriggers to support bigger loads and larger objects.

Screwdrivers

Screwdrivers are used to fix screws. Power drills and electric screwdrivers are not always superior to manual screwdrivers. Manual screwdrivers don’t fall off since their heads are affixed to their bodies.

Additionally, using manual screwdrivers enables more accurate screwing and unscrewing. On the other hand, using electric screwdrivers generally helps to complete the work faster.

Depending on your needs, you may choose a manual or electric screwdriver for your mezzanine construction.

Wrenches

While building a mezzanine floor, you have to use many nuts and bolts. The wrench is an instrument that is typically sized for a specific kind of nut or bolt.

The open head’s metal edges can firmly grasp a nut of a certain size. As a result, the worker can twist the tool to tighten as well as loosen the nut.

Safety Helmet

Any object or structure could fall while development is underway. A safety helmet needs to be worn in needed to shield the head from harm or any tragic accidents.

Gloves

To work safely, workers should use gloves while working.

Telehandlers

That extra flexibility can be provided by telehandlers while building large objects. Because of the additional flexibility, it affords in putting big objects into place.

Sledge Hammers

Whenever the ground is hard, a sledgehammer can be used. The hardwood handle has a huge weighted metal head that can be used to crack tough layers. As a result, digging becomes easier.

How To Build A Mezzanine Floor For Warehouse?

After you have decided on you’re preferred type of mezzanine floor, it’s time to build it. Now, we will give you a detailed step-by-step guide related to the mezzanine floor installation.

Mezzanine design planning prior to building a mezzanine floor

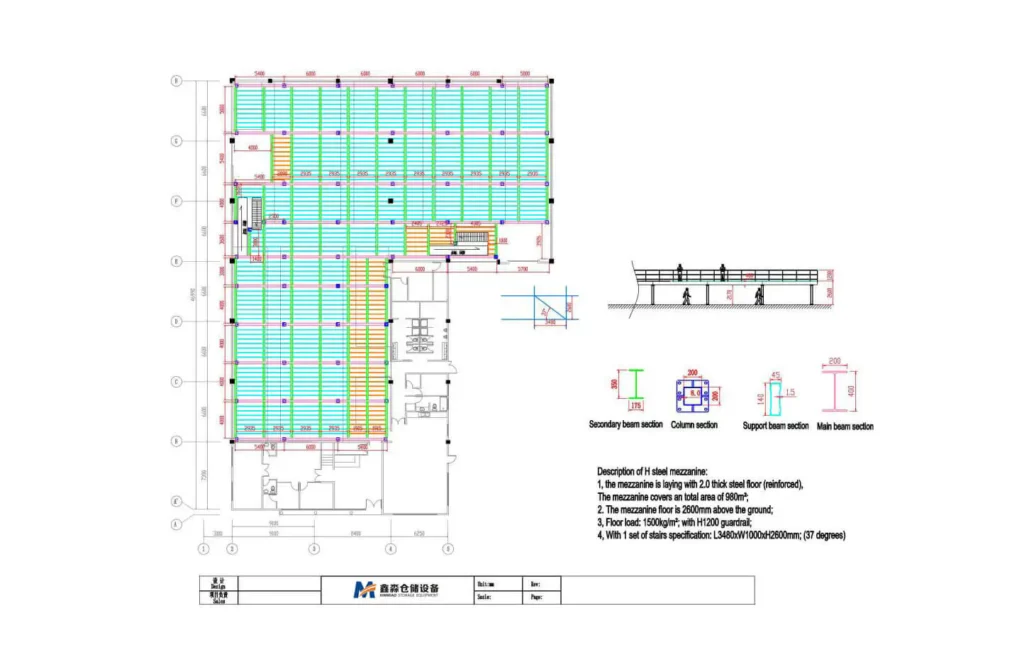

Before building the mezzanine floor, it’s necessary to have a design of the mezzanine floor. The mezzanine floor drawing should at least include the following things:

Planning The Layout Of The Mezzanine Floor

Establish the overall dimensions of the mezzanine that you require (width and length). It should clearly state in the design how many columns and primary beams the mezzanine floors should have.

Then, establish the clearance height that is required. You might need to allow enough height so that your forklift can pass underneath the mezzanine.

While you lay out the design of the mezzanine floor, it is recommended to contact a structural engineer. The largest product you will keep on the mezzanine will determine the size of steel that is needed. Depending on the weight per m2 footprint, this calculation was made.

A typical weight capacity utilized in mezzanine floor engineering calculations is 500 kg/m2. A structural engineer is needed to calculate this type of calculation.

If you want to know more about mezzanine floor design related topics, please read mezzanine floor design.

Adequate security

The most crucial aspect to take into account while building mezzanine floors is safety. For instance, handrails are required on any stairs that lead to the mezzanine floor of the warehouse.

If the floor is open, you must make sure that a guardrail is installed. A guardrail will prevent people from falling from the mezzanine floor edge.

You should consider fire safety into consideration too, regardless of usage or building regulations. It is strongly advised that you consider safety when making plans and get expert advice.

Safety and the number of columns and beams should be specifically included in the mezzanine floor design. There are also other things like stairs, guardrails, etc should be included in the mezzanine floor design. We will discuss these things in the later part of this article.

Cleaning The Area Where The Mezzanine Floor Will Be Installed

You should keep the space clean where the mezzanine floor will be installed. If there is any kind of debris or trash in that place, it should be removed.

Slab Capacity

Slab capacity should be considered while building the mezzanine floor. Warehouses should have at least 125 PSF (Pound Per Square Foot) slab capacity. In warehouses, the floor slab should be at least six inches thick.

The Description Of The Construction Work Of The Mezzanine Floor

Using concrete bolts, plate the bottom of the columns and screw them to the ground. You will need to use a drill machine to attach the plate of the columns to the ground.

After you have successfully attached the plate of the column, then cut the column to the desired height. Also, cut the beam to the desired mezzanine length.

Beams and columns are the main structures of the mezzanine floor. After successfully completing steps 1 & 2, now attach the column and beams of the mezzanine floors.

After the formation of the main structure, now put the mezzanine platform on top of the columns and beams. Make sure the screws of mezzanine platforms are properly attached to columns and beams.

Without building the stairs, the construction of the mezzanine floor is incomplete. To climb the platform of the mezzanine floor, using the stair is necessary, After you have created the mezzanine platform, now is the time to construct mezzanine stairs.

You can construct the stairs by adding the handrails of the stairs first. Then, attach the steps of the stairs one by one with the handrails. Make sure you have maintained the exact distance of the steps of the stairs.

After successfully constructing the mezzanine platform and stairs, now it’s time to install guardrails. Guardrail ensures the safety of the goods and workers who will work on the side of the mezzanine platform.

Attach the guardrail to the mezzanine platform’s ground with screws and plates. Use drill machines to attach it faster to the ground. Make sure the guardrails you are installing cover the entire side of the mezzanine platform.

Mezzanine floors can function without guardrails. However, warehouse owners should install it for their benefit. Because it will give protection to the workers and goods from falling.

Columns, Beams, Guardrails, Stairs, Braces

While building a mezzanine floor, it is very especially important to install the following things properly:

- Columns- The more columns you have, the less load each column will hold. However, having many columns should not obstruct the walking space under the mezzanine platform.

- Beams- The beams are very crucial as it transfers the load to the columns. There are two types of beams, primary beams, and secondary beams. Primary beams transfer the load to the columns and secondary beams support the primary beams.

- Guardrails- Guardrails give edge protection to the mezzanine floor. Guardrails can help to maintain balance if someone slips the balance on the mezzanine floor.

- Stairs- No matter which type of mezzanine you select for the warehouse, it must have stairs to climb on. A durable stair is needed in the warehouse as it will be used to carry loads. Handrails should be installed on the sides of the stairs.

- Braces- Cross braces and knee braces are the two most popular types of bases. Braces provide additional support for machinery.

To know more about how these things should be installed on a mezzanine floor, mezzanine floor installation will be helpful.

Post Installation Checking Of The Mezzanine Floor

Once you have successfully installed the mezzanine floor, now it’s time to check if everything is alright. The calculation is a major part of the construction of the mezzanine floor. So, make sure distances like the column to column, steps to steps of stairs, etc are maintained.

You can use a measuring tape to accurately measure the distance. Also, check if the screws are tightened properly.

Now, your warehouse mezzanine floors are ready to use! Keep it as storage for goods in your warehouse or use it for other purposes as well.

What Is The “International Building Code (IBC)”?

Internation Building Code is a set of rules and regulations related to buildings. International Building Code has also some regulations related to the mezzanine floors.

The latest version of the International Building Codes is 2021. IBC is followed in most of the states across the USA.

Following The Mezzanine Floor Building Codes Of Your Country

There may be specific mezzanine floor laws that are legislated in your country. For instance, in the USA, the “International Building Code(IBC)” is widely followed for mezzanine floor-related regulations.

Similarly, you should find out the relevant law related to the mezzanine floor of your country and follow it.

What Is The Rule And Regulations Of The International Building Code Related To The Mezzanine Floor?

There are some specific rules and regulations of the IBC related to the mezzanine floors. About the height, the International Building Code states in chapter 5; section 505.2,

“A mezzanine or mezzanines in compliance with Section 505.2 shall be considered a portion of the story below. Such mezzanines shall not contribute to either the building area or number of stories as regulated by section 503.1.”

“The area of the mezzanine shall be included in determining the fire area. The clear height above and below the mezzanine floor construction shall be not less than 7 feet(2.1336 meters).”

So, the height of the mezzanine platforms above and below should not be less than 2.1336 meters. About the openness of the mezzanine floor, section 505.2.3 states,

“A Mezzanine shall be open and unobstructed to the room in which such mezzanine is located except for walls not more than 42 inches (1.0668 meters) in height, columns, and posts.”

This IBC also states that you should not have a mezzanine floor of more than one-third of the warehouse’s ground. According to section 505.2.1 of the International Building Code,

“The aggregate area of a mezzanine or mezzanine within a room shall not be greater than one-third of the floor area of that room or space in which they are located.

The enclosed portion of a room shall not be included in a determination of the floor area of the room in which the mezzanine is located. In determining the allowable mezzanine area, the area of the mezzanine shall not be included in the floor area of the room.”

So, these are some of the regulations of the International Building Code related to the mezzanine floors.

Is Following The Rules And Regulations Of The International Building Code Mandatory?

No, following The International Building Code is not mandatory at all in countries except the USA.

The majority of the states of the USA follow the International Building Code. So, these regulations do not apply to warehouses located outside the USA.

The rules and regulations of the International Building Code are very logical. If warehouses follow these rules and regulations, it is for their good.

Do You Need Planning Permission To Build A Mezzanine?

No, you don’t need planning permission to build a mezzanine floor.

The mezzanine floor which is constructed in the warehouse is mostly temporary. It is built upon the floor of the warehouse. It can be easily assembled and disassembled too. That’s why no planning permission is needed to build a mezzanine floor in the warehouse.

Cheapest Way To Build A Mezzanine Floor.

Mezzanine floors are custom-made. So, it is almost impossible to get a second-hand mezzanine floor from any other warehouse. So, you have to buy mezzanine floors from the manufacturers.

The first way to build a mezzanine floor is to buy the mezzanine floor from China. The price of the mezzanine floor is cheaper compared to the western nations.

This is because Chinese factories can produce mezzanine floors in huge quantities. Additionally, the labor cost in China is lower compared to the western nations.

You should also install the mezzanine floors from Chinese manufacturers too. Because their installation cost is lower than other European and American countries.

So, ordering and installing the mezzanine floor from China is the cheapest way to build a mezzanine floor.

If you want to learn more about issues related to mezzanine floor cost, pleas read mezzanine floor cost.

This article discusses in great detail how to build a mezzanine floor. Feel free to contact us for any kind of inquiry related to building a mezzanine floor.