Efficient use of storage space is crucial for the effective management of a warehouse or storage facility. Pallet racks offer an organized and efficient solution to maximize storage capacity while providing easy access to goods. However, without proper anchoring, pallet racks can become unstable and pose a significant risk to worker safety, product integrity, and even structural stability.

In this article, we will take a closer look at anchoring pallet racks, including the components of pallet racks and the different types of anchors used.

By implementing proper anchoring techniques, businesses can maintain a safe and productive work environment, prevent accidents, and protect their products and equipment from damage.

First, our two bits on why is properly anchoring pallet racks necessary.

Why Are Properly Anchoring Pallet Racks Important?

Properly anchoring pallet racks is necessary for ensuring the safety of employees and inventory safety and promoting long-term productivity and profitability. When pallet racks are not anchored properly, they can pose significant hazards, including rack collapse, falling objects, and damage to surrounding equipment and inventory.

Alternatively, properly anchored pallet racks offer several important benefits, some of which are discussed below.

Proper Anchoring Means Safety

One of the most significant benefits of properly anchored pallet racks is safety. When racks are appropriately anchored, they are more stable and less likely to shift, lean, or collapse, which helps to reduce the risk of injury to employees and damage to inventory. Proper anchoring also helps to ensure that racks are able to support their intended loads without the risk of failure.

Proper Anchoring Ensures Productivity

Another important benefit of properly anchored pallet racks is productivity. If racks are stable and secure, employees will be able to work more efficiently and with greater confidence, which can improve overall productivity. It also plays a critical role in preventing damage to inventory and equipment, reducing the risk of downtime and delays due to repair or replacement.

Industry Regulations

Industry standards and regulations often require proper anchoring. By ensuring that pallet racks are properly anchored, businesses can avoid potential fines and legal issues and maintain compliance with relevant safety and building codes.

Other Benefits

Properly anchored pallet racks also offer long-term benefits for businesses. Businesses can avoid costly legal fees, insurance claims, and repairs by reducing the risk of accidents and damage. Additionally, properly anchored racks can last longer and require less maintenance, which can lead to significant cost savings over time.

Overall, properly anchoring pallet racks is essential for ensuring the safety of employees and inventory, promoting productivity, and maintaining long-term profitability for businesses.

Understanding Different Components of Pallet Racks

To help you anchor your pallet racks the right way, it is essential to consider the different components pallet racks are made up of. Let’s take a cursory look at each of the components.

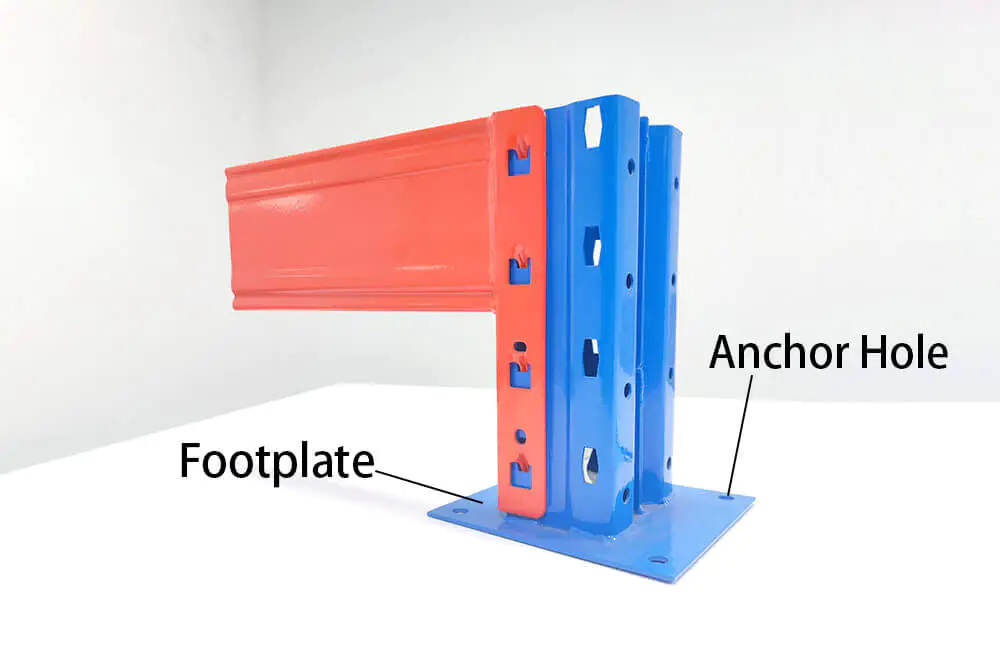

Uprights

Uprights are vertical components of the pallet rack that support the weight of the load. They are typically made of steel and come in a variety of sizes and capacities. The size and capacity of the uprights depend on the load requirements and the dimensions of the pallets being stored.

Beams

Beams are horizontal components that connect the uprights and support the weight of the load. They are typically but not necessarily made of steel and come in various capacities and configurations. The length and capacity of the beams depend on the dimensions of the pallets being stored and the weight of the load.

Braces

Braces are diagonal components that provide lateral stability to the pallet rack. They connect the uprights and prevent them from leaning or swaying. Braces are typically made of steel and come in a variety of sizes and configurations. The braces’ size and configuration depend on the pallet rack’s height, width, and load requirements.

Wire Mesh Decking

Wire mesh decking is a standard accessory used with pallet racks. It is a grid-like surface that is placed on top of the beams to provide a flat surface for the pallets to sit on. The wire decking is typically made of steel and comes in a variety of sizes and capacities. It helps to distribute the weight of the load and prevent damage to the pallets.

Row Spacers

Row spacers are used to provide additional support and stability to the pallet rack. They are placed between the uprights to maintain the correct distance between them and prevent them from leaning or swaying. Row spacers are typically made of steel and come in a variety of sizes and configurations. The row spacers’ size and configuration depend on the pallet rack’s height, width, and load requirements.

Most Commonly Used Anchoring Methods

There are several types of anchors that can be used to secure pallet racks in place. Depending upon the type of pallet racks you choose to install, you may be required to use an anchor or a combination of a few from the following.

Floor Anchors

Wedge Anchors

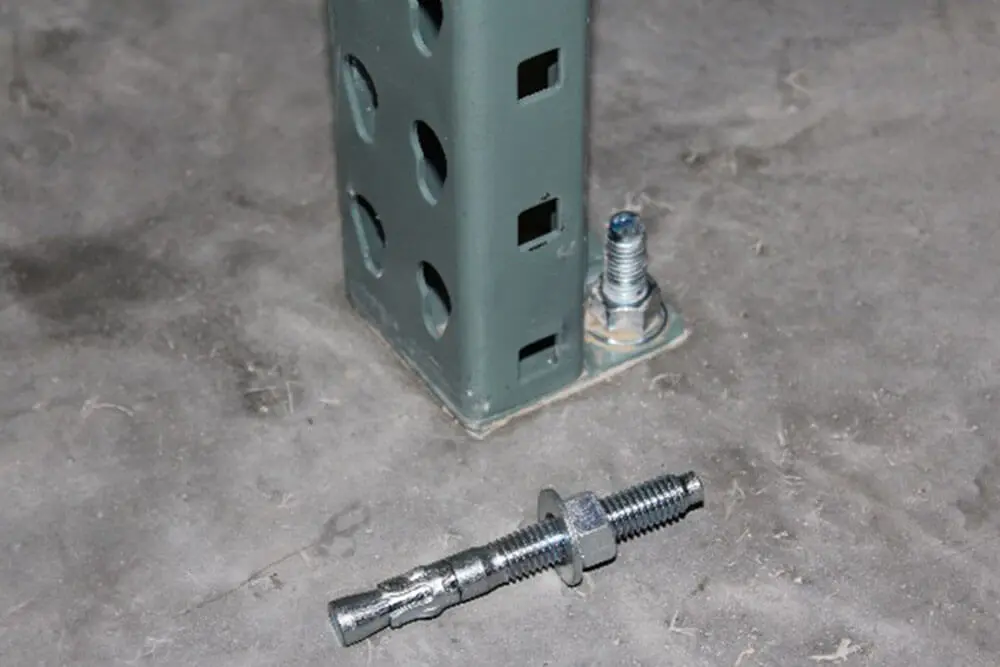

Wedge anchors are a type of floor anchor that is commonly used to secure pallet racks to the floor. They are inserted into a pre-drilled hole in the concrete and then expanded by tightening the bolt. The expansion creates a strong and secure hold that keeps the pallet rack stable.

Sleeve Anchors

Sleeve anchors are used when the concrete is not strong enough to hold a wedge anchor. They are inserted into a pre-drilled hole in the concrete and then expanded by tightening the bolt. The sleeve expands as the bolt is tightened, creating a tight fit that helps to secure the pallet rack in place.

Expansion Anchors

Expansion anchors are used for securing pallet racks to the floor. Like other types of anchors, they are also inserted into a pre-drilled hole in the concrete and then expanded by tightening the bolt. The expansion creates a tight fit that helps to keep the pallet rack stable.

Concrete Anchor Bolts

Concrete anchor bolts are a type of floor anchor used to secure pallet racks to the concrete floor. A hole is drilled in the concrete, in which they are inserted and then tightened with a nut and washer. The bolt threads into the concrete, providing a secure hold.

Wall Anchors

Lag Bolts

Lag bolts are wall anchors commonly used to secure pallet racks to the wall. They are placed into a pre-drilled hole in the wall and then tightened with a wrench. The bolt threads into the wall, providing a secure hold.

Expansion Shields

Expansion shields are used to secure pallet racks to the wall. You must insert them in a pre-drilled hole and then expand it by tightening the bolt. The shield expands as the bolt is tightened, creating a tight fit that helps to keep the pallet rack stable.

Sleeve Anchors

Sleeve anchors are used when the wall is not strong enough to hold a lag bolt. They are placed into a pre-drilled hole in the wall and then expanded by tightening the bolt. The sleeve expands as the bolt is tightened, creating a tight fit that helps secure the pallet rack.

Wedge Anchors

Wedge anchors are a type of wall anchor that is used to secure pallet racks to the wall. Same as above, they are inserted into a pre-drilled hole in the wall and then expanded by tightening the bolt. The expansion creates a strong and secure hold that keeps the pallet rack stable.

Column Anchors

J-Bolts

J-bolts are used to anchor pallet racks to a building’s structural columns. They are inserted into a pre-drilled hole in the column and then tightened with a nut and washer. The bolt threads into the column, providing a secure hold.

Expansion Anchors

Expansion anchors are used for securing pallet racks to the building’s structural columns. They are inserted into a pre-drilled hole in the column and then expanded by tightening the bolt. The expansion creates a tight fit that helps to keep the pallet rack stable.

Concrete Anchor Bolts

Concrete anchor bolts are a type of column anchor that is used to secure pallet racks to the building’s structural columns. They are inserted into a pre-drilled hole in the column and then tightened with a nut and washer. The bolt threads into the column, providing a secure hold.

Now that you understand the pallet rack components and different types of anchors used in pallet racking, let’s move to the most important part: How actually to anchor pallet racks?

How to Anchor Pallet Racks?

A core part of the pallet rack installation is anchoring, as it ensures the safety and stability of the storage system. A trained professional should perform the anchoring process and follow the manufacturer’s instructions and local building codes.

Here are some general steps to follow for anchoring pallet racks:

Determine the Type of Floor

The type of floor will impact the type of anchor used. For example, concrete floors require anchors with a larger diameter and greater holding strength than wood or metal floors. You have to select anchors that are appropriate for the specific type of floor to ensure that they will be able to support the weight of the pallet rack and its contents.

Choose the Appropriate Anchors

The type of anchor used will depend on the pallet rack load requirements and the floor type. Wedge anchors, for example, are commonly used for concrete floors and provide a secure hold that resists pull-out and vibration. Sleeve anchors are another option for concrete floors and are easy to install but may not be as strong as wedge anchors. Expansion anchors can be used for concrete or masonry walls and are designed to expand when tightened, creating a secure hold. Concrete anchor bolts are another option for concrete floors and provide an excellent grip.

Install the Anchors

When installing the anchors, it’s important to follow the manufacturer’s instructions carefully. This may include drilling holes in the floor or wall, inserting the anchor, and tightening it down with a wrench. It’s important to ensure that the anchors are installed to the correct depth and torque for a secure hold.

Attach the Uprights to the Anchors

Once the anchors are installed, the uprights of the pallet rack can be attached to them. The uprights should be securely fastened to the anchors using bolts or other fasteners. It’s important to ensure that the uprights are plumb and level to prevent any leaning or instability.

Install the Beams and Braces

With the uprights securely anchored, the beams and braces can be installed. They should be securely fastened to the uprights and each other to ensure stability and prevent swaying or leaning. It’s important that the beams and braces are installed at the correct spacing to support the intended load.

Perform a Load Test

After the pallet rack is fully assembled, perform a load test to see that it can safely support the intended load. This may involve loading the rack with a test weight and checking for any signs of instability or sagging. It’s important to perform this test before loading the pallet rack with actual inventory to ensure that it is safe and stable.

Concluding Thoughts: How to Anchor Pallet Racks?

Proper anchoring of pallet racks is vital for the safety and stability of any warehouse or storage facility. Unanchored or improperly anchored pallet racks can pose serious risks to employees and inventory, including collapse, toppling, and damage. The anchoring process for pallet racks requires careful consideration of the type of floor, appropriate anchors, installation process, and load requirements. By following these steps and ensuring that pallet racks are securely anchored, warehouse and storage facilities can create a safe and stable environment for employees and inventory.

Lastly, it is important to regularly inspect pallet racks to ensure that the anchors remain secure and that the racks continue to meet load requirements. A well-anchored pallet rack system can provide a safe and efficient solution for storing inventory and optimizing space in any warehouse or storage facility.