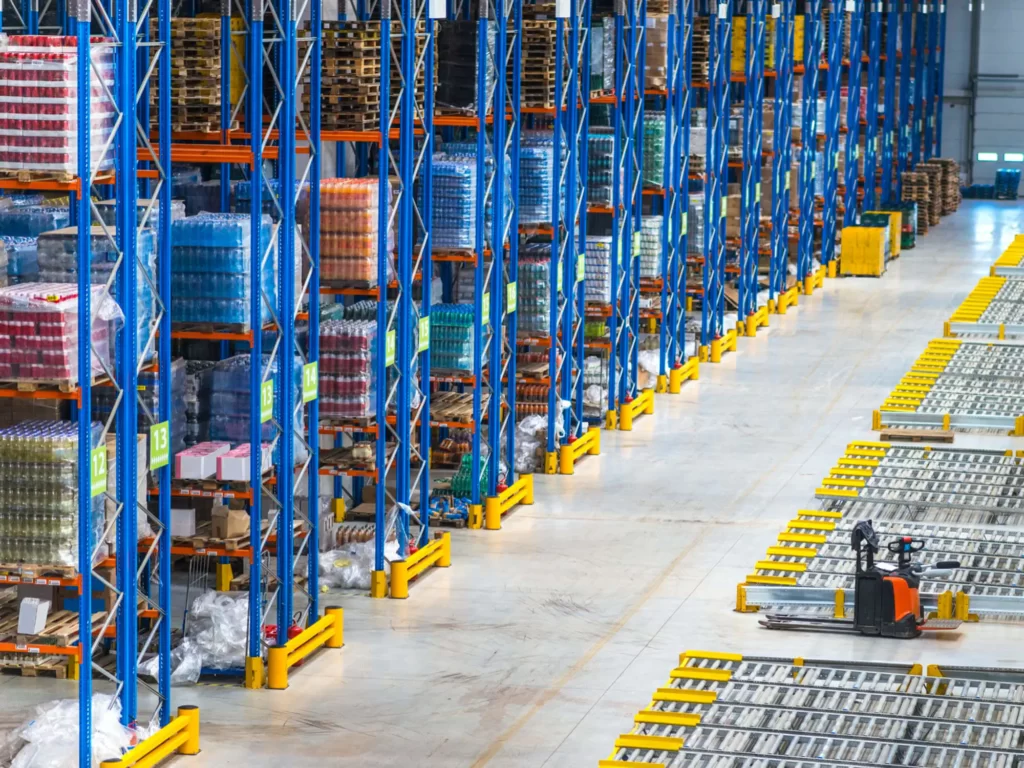

Selective pallet racks are more equipped with roadway stackers and other storage and transportation machinery for operation, in which the high-rise rack are mostly integrated structures, generally made of steel welded rack, and then connected by horizontal and diagonal rods and beams and other components. At present, the free combination is used, which is easy to disassemble and move. The position of the beam can be adjusted arbitrarily according to the height of the stacking of items, which can also be called an adjustable pallet shelf. Generally, the material used for pallet racks is mostly steel structure, and reinforced concrete structure can also be used. It can be made into a single row connection, can also be made into a double row connection, and the size of the pallet storage rack, generally according to the size of the warehouse and the size of the pallet size; At the same time, Mracking also reminds us that when choosing pallet storage rack, we should also consider the size, quality and stacking layer of the storage unit, to facilitate the decision of upright and beam size.

Pallet racks are more advantageous in terms of structure:

1) Structural design: from the point of view of structural design, it adopts double row diamond hole design, the diamond hole and the suite on the beam are reasonably inserted, so that the disassembly and assembly are more convenient, but also can join the safety pin fixed more firmly insurance; Moreover, it also conforms to the mechanical design, the beam upright will be thickened, bearing capacity is also strong strength, its bearing range is about 3000kg bearing; It is also suitable for all kinds of occasions to complete the task of goods storage.

2) Material: From the material aspect, it can be seen that pallet racks are all made of cold-rolled steel, the steel produced by cold-rolled steel has a smooth and bright surface, and belongs to a kind of steel with wear resistance and high strength, so the rack is more durable.

3) Performance: just from its performance characteristics, pallet storage rack utilization rate is higher, access is more convenient, and is a common, economic, safe rack, it is suitable for all types of warehouses, also can form a variety of storage.

What are the advantages of pallet rack compared with the ordinary rack?

1) Pallet rack can realize mechanized loading and unloading operations, can also facilitate the storage of unitary goods, but also improve the utilization rate of storage capacity;

2) Can also improve labor productivity, to achieve high efficiency of goods access operations, easy to achieve computer management and control;

3) Generally, pallet racks do not need shelving panels, they only need beam and crossbeam, and each pallet is generally installed 2 crossbeams, such pallet storage shelf to the greatest extent to save cost;

4) The number of layers of storage pallet rack can be determined according to the height of the warehouse, the height of each pallet space, and other conditions, so the bottom can not be beam, pallet directly placed with the ground.

5) Pallet storage rack makes goods easy to access freely, each pallet storage point is a pallet position, set a goods number, the forklift can access the pallet goods at any number of goods position.

Since pallet racks have such a big advantage, then most of the problems will come, such as the choice of pallet storage shelf, pay attention to what when goods storage, warehouse pallet rack in the installation of what should be paid attention to? Now, Mracking rack will answer your questions one by one!

What problems and matters needing attention will be encountered when accessing goods on pallet shelf:

When we load goods with pallets, if the pallets are stacked directly, the following problems will occur, for example:

1) When each pallet is loaded with different goods, only single operation can be carried out, which can not be stacked, otherwise, it will cause storage capacity reduction;

2) When stacking directly with flat pallets, it should be noted that the goods between the two pallets and the lowest layer will be squeezed, and even more serious will cause damage to the goods, and this stacking method can not achieve the first-in, first-out mode of goods access;

3) If the upright pallet or frame pallet is used, stacking can be carried out and the goods will not be squeezed, but stacking can not be too high, too high and too thick will cause poor stability, and it is not safe; So how do we solve these problems? When faced with the above problems, we can use pallet shelf, each pallet occupies a cargo space so that we can overcome the above problems. And it should also be noted that the higher pallet shelf use stacking cranes to access goods; The lower pallet shelf can be accessed by forklifts;

When the pallet rack installation, what are the problems which are we need to pay attention to small details:

now in Mracking drive-in rack as an example to see the installation: Mracking drive-in rack, is a kind of not to channel segmentation, continuity of the whole rack, on the support guide rail, pallet needs to deposit according to the depth direction, one follows one so that we can increase its density. At the same time, the drive-in rack can be used by forklift trucks to access the goods in the channel, which is suitable for the storage of goods with few varieties and large quantities. Compared with the goods rack, the storage space utilization rate of the drive-in rack can be increased by more than 30%. usually, the rack height can be as high as seven or eight meters, installation, welding can only start from the ground, step by step upward installation, the difficulty coefficient is also quite large.

So when installing Mracking drive-in rack, we need to pay attention to some small details:

First: to be strictly carried out in the stipulated warehouse area, can not occupy more channel area, to prevent forklift can not enter the work. When the installation exceeds the planned installation area, the warehouse manager must be informed;

Second: rack installation must start from the bottom, and gradually upward, can not be from the airlifting rack for workers to install, summary, installation only from down to up transport material efficiency is highest, with the aid of tower crane, it is easy to reduce efficiency, and accident;

Third: rack installation needs to first upright, then beam, shelving panel at last;

Fourth: when the screw must be from bottom to top, there is a need to perforate the emergency situation, must be removed after the rack drilling, so as not to high space working unnecessary situation;

Fifth: rack placed back to back, must be two sets of rack by the bottom connected before the second layer of rack installation operations;

Sixth: because the rack surface is smooth, Mracking storage center recommended engaged in the installation of staff should wear gloves;

Seventh: after the rack is installed, it must be strictly checked again;

Ninth: tell the storage manager the rack maintenance method, to facilitate the daily maintenance and maintenance of the rack.

Mracking storage center also reminds us of the most important points, that is in the use of any rack, we should pay attention to the following three points:

1) anti-overload, no matter what type of rack, shall not exceed the approved weight of the rack;

2) Anti-impact, when accessing goods, forklifts and other mechanical equipment must be rigorous and strictly in accordance with the operation, to prevent hitting rack;

3) not to change the rack structure at will.