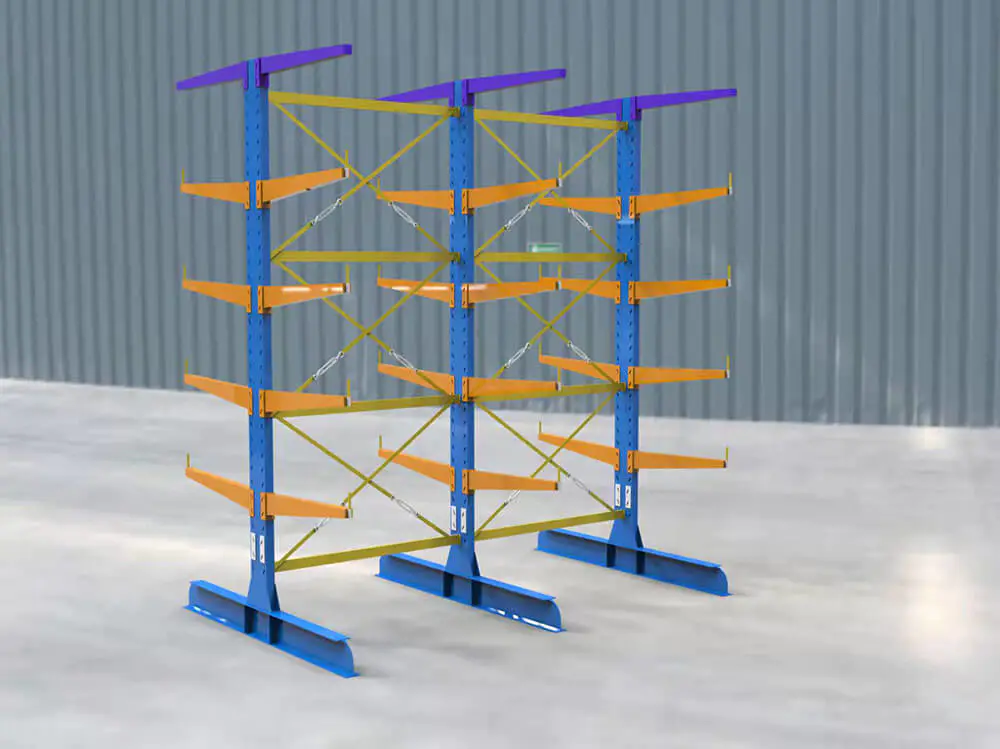

Cantilever racking, mainly the racks composed of column pieces, cantilever arms, connecting rods, etc. Cantilever racks use special profile columns, which are characterized by the light structure of the front-extended cantilever, strong loading force, with a high-strength cantilever, suitable for storing long, ring-shaped, plate and irregularly shaped heavy materials. And according to the load capacity can also be divided into light, medium and heavy cantilever racks three. The cantilever can be single-sided or double-sided. When it adds wood or steel plates, it is especially suitable for low-density and small-space storage, and it is also more convenient and fast in warehouse management, which is of great help to improve the utilization rate of a warehouse.

The basic structure of cantilever racking.

The column of cantilever storage racks is mainly made of two pieces of cold-rolled C sections welded face to face, and there are double rows of holes punched in the column, and the distance of the hole section is generally 140 (50) mm, so that when the cantilever arm is hung on it, the height of each layer can be freely adjusted up and down. The length of the cantilever racking is also free to match.

Cantilever racking features.

1. Using structural steel

The steel used in cantilever racking is strong and durable, and it does not rust. Mracking racks and equipment raw materials are from Baosteel, Shaogang and other large national steel enterprises cold rolled steel coil, each batch of steel has a strict test certificate, from the source to ensure the quality of racks and equipment.

2. High load-bearing capacity

The load specification of cantilever racking and flexible design. A Cantilever pipe rack is mainly used to store long and irregular materials, and its specifications can be designed according to the user’s requirements for the racking, but the load range must be calculated according to the load of the arm, and generally, the load per arm does not exceed 800kg.

3. Assembled structure

Cantilever shelves are all combined, easy to disassemble, transport, adjust, move, etc., safe, reliable, stable, and have strong load capacity. Because its cantilever can be made single-sided or double-sided, its height is generally within 5.0 meters, with the characteristics of stable structure, good load capacity and high space utilization.

4. Three-dimensional design

Cantilever shelves belong to three-dimensional design drawings and multi-side presentation. And cantilever shelf three-dimensional drawings have front and side view displays, in its design, the biggest feature is the arm needs to have a blocking piece, the intention is to avoid the decline of goods, and the arm is tilted upward.

5. Adjustable level height

The cantilever rack adopts adjustable columns, users can adjust the distance between the cantilever and increase or decrease the cantilever according to their actual needs.

6. Use with forklift and stacker

Cantilever racking can be matched with a stacker crane or forklift, which can improve the efficiency of material circulation, reduce the cost of storage and transportation, and increase the economic benefit.

The 10 advantages of Mracking cantilever racking system.

1. Free combination

Cantilever racking system structure can be freely assembled, it is a type of racking that can be disassembled and assembled as well as transported, adjusted and moved freely, such racking can improve the inventory of the warehouse and enhance the planning and design of the warehouse.

2. Guarantee rack quality

Cantilever racks can effectively ensure that the goods can maintain a certain quality when stored, and can effectively avoid moisture and damage.

3. Cantilever arm can be single-sided or double-sided

The arm of cantilever racks can be designed into single-sided cantilever racks or double-side cantilever racks according to the situation of the warehouse site, so that the goods can be placed against the wall, loaded into the goods from one side, and then the goods can be arranged in the center of the warehouse to facilitate the entry of goods, so as to improve the storage situation of the warehouse.

4. High-quality column and base

Cantilever racking system columns and bases are generally of I steel or cold rolled steel, and the cantilever can be advantageous steel or square tube, these three accessories can be locked with bolts, and can generally carry a range of 2 to 3 tons of weight.

5. Customizable cantilever racking

Can add wood spacers or rubber padding to the cantilever, the purpose is to prevent damage to the material, and the specifications and load-bearing of the cantilever racks are not set in stone, the user can customize them according to actual needs.

6. Additional facilities can be added

For the convenience and flexibility of goods storage, like some bulk and not only bulky goods, you can add steel plates or wooden boards or mesh on the cantilever arm, so that the cantilever shelves with increased facilities are also more suitable for warehouses with low floors and small spaces.

7. Racking unit

A cantilever racking system is a row of racks formed by connecting multiple columns, not individual racks, and each of its racking units can sort and store different types of goods, and can effectively store pipes, wood, strips and other similar goods.

8. Adjustable cantilever length

The length of cantilever shelves can be freely combined and adjusted according to the actual site conditions.

9. Labor-saving

A cantilever racking system can reduce labor intensity and improve labor conditions, and can also improve the mechanization of material circulation.

10. Anti-corrosion racks

Mracking cantilever rack belongs to anti-corrosion racks, with high corrosion resistance racks, it adds Al, Mg, Ni, Cr and other alloys of special steel, and a certain range of Al, Mg, Ni, Cr content increases so that the steel plate than the general plate corrosion resistance increased by several times to more than ten times. Furthermore, the surface treatment of anti-corrosion racks plays a pivotal role in the whole production process, Mracking anti-corrosion racks in the pre-processing treatment, processing equipment debugging, post-processing treatment, surface passivation treatment, coating methods are through layers of strict control to ensure the anti-corrosion performance of the racks, and for the problem of sealing the coating, but also the use of high corrosion-resistant coating secondary coating process, which greatly improves The sealing of the coating.

Cantilever racking system disadvantages.

- only able to store long materials.

- Relatively high input cost.

- High requirements for construction site ground.

- High requirements for workers’ safety operation.

Cantilever racking production materials.

Cantilever racks are generally made of two materials, namely:

1. C-steel production: cantilever rack according to the corresponding cantilever layer load requirements, first selected c-steel specifications, selected after the two pieces of c-steel butt welding, welding in one end after welding anti-slip shield, the other end welding connection u-column connectors.

2. Square tube production: according to the corresponding cantilever layer load requirements, the cantilever rack first selects the square tube that meets the layer load requirements, cut it into the required size, welds the anti-slip guard at one end, and welds the u-shaped column connection at the other end.

Mracking heavy duty cantilever racking production process.

1. PLC control

The cutting error of Mracking’s production material is generally within 0.2mm, which is much smaller than the national standard of 1mm.

2. The cold-forming machine

The structure of the laminate is one piece of eight bends, and the back plate is one piece of four bends and once formed, while the bending part does not need welding at all.

3. Stamping equipment

Stamping equipment, which includes a bracket arm, R angle, column punching, etc., are independent punching machine to complete, and no need to change the mold, so it is a good guarantee of the rack and equipment’s accuracy and production efficiency.

4. Double-seam automatic welding

Mracking adopts multi-directional fixed and automatic welding so that the welding efficiency is more efficient and the welding seam is flat and even.

5. Primary processing process

Mracking’s primary processing process generally adopts high-quality steel forming and processing equipment, which is customized by the leading domestic mold manufacturer according to the customer’s requirements. The production process includes primary processing, precision rolling, automatic welding and forming, removal of appearance defects, inspection, etc.

6. Rust removal process

Mracking adopts the more energy-saving and environmentally friendly vitrified process instead of the traditional phosphate surface treatment process and has invested a lot of money to build its own sewage harmless treatment facilities (water washing to remove surface dust), thus ensuring that the whole rust removal process is more environmentally friendly (neutral degreasing, vitrified, passivation), and at the same time guaranteeing the higher functional characteristics of the racks and equipment.

7. Spraying equipment

Mracking adopts automatic spraying equipment, electrostatic spraying, so as to ensure the quality of the surface paint film, as well as to ensure that the surface paint film brightness and thickness of the racks and equipment can reach uniformity.

Applications of cantilever racking.

1. Heavy-duty cantilever racks are mostly used in the machinery manufacturing industry and building materials supermarkets, etc.

2. It is suitable for storing long materials, ring-shaped materials, plates, pipes and irregular goods.

3. With the addition of racks, it is especially suitable for warehouses with small spaces and low height, convenient management, wide view and higher utilization rate than ordinary racks.

4. Cantilever racks are made by installing an external cantilever on the traditional rack pillars, which is a kind of special rack for long-shaped goods.