If an e-commerce company wants to grow, it is necessary to have access to e-commerce warehousing and offline warehousing. Why do you say that? Because e-commerce warehousing and offline warehousing are both corporate logistics activities, which is what we often call the supply chain. But these are inseparable from the inventory, the inventory is too large, and the cash flow pressure is high. The inventory is low and the transaction success rate is low. Therefore, how to balance the relationship between supply and demand, it is necessary to do a good job in warehouse management and reduce the company’s operating costs.

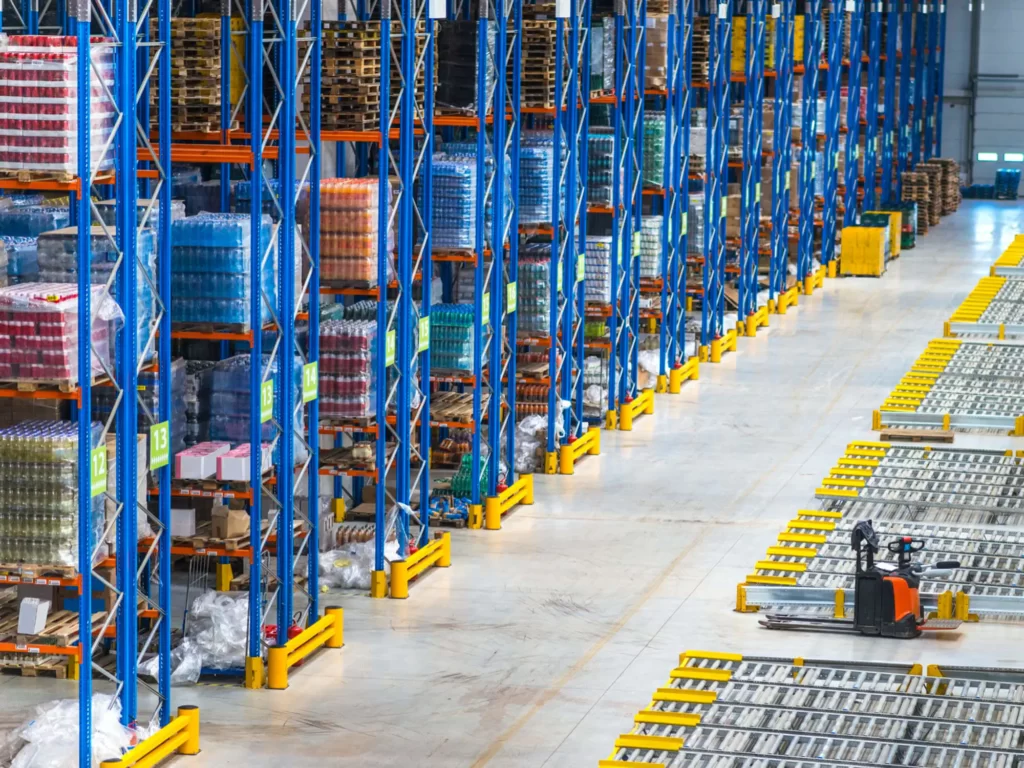

Through the analysis and comparison to reflect the characteristics and difficulties of e-commerce stores, so as to provide direction for e-commerce warehouse rack system planning. We will share with you how to seize the time to adjust and optimize various warehousing processes during the off-season of e-commerce, so as to make adequate preparations for the e-commerce promotion.

Through the comparison of online warehouses and offline warehouses, we can see that e-commerce warehouses have the following five characteristics:

(1) Unknownness of the order: the order has no plan, and the order information cannot be predicted in advance.

(2) Volatility of orders: Big promotions have a greater impact on order fluctuations.

(3) Flexibility of personnel: fluctuations in orders require more flexible deployment of personnel.

(4) Fragmented warehousing: inventory is getting closer to consumers.

(5) Diversification of platforms: Businesses on different platforms require different processes.

According to the characteristics of e-commerce, Mracking recommends e-commerce merchants to optimize e-commerce storage in the following aspects.

- E-commerce warehousing planning

Warehouse when we are doing the overall planning, electricity, you first need to collect 1-3 months of key data, such as product information, daily orders, production efficiency, inventory quantity and so on, analyzed the characteristics of the shipment and business orders to preliminarily determine the required size warehouse, warehouse shelf type and quantity of the applicable, equipment and material selection and configuration of personnel and the business process, etc. At the same time, it is necessary to analyze the daily data and the data of the big promotion activities, so as to comprehensively consider the various data to create a warehousing model.

- Warehouse layout planning

According to the previous data analysis results, when planning functional areas, you should also pay attention to the moving lines between various functional areas and within a single functional area, reserve main and auxiliary channels, and pay attention to the width of each channel in warehouses with counterweights or reach forklifts. Reserve a safe distance.

- Picking route planning

“S” picking moving line: the picker in the whole picking area with a big “S” path to walk pick goods, into the roadway after the “Z” or “S” of the route pick goods; This kind of picking moving line is more suitable for the warehouse with middle partition racks, and can realize the shortest path of picking goods.

“U” picking moving line: pickers in the whole rack periphery and the roadway are size “U” moving line to pick goods, this picking moving line is more suitable for the wide width of the high three-dimensional rack area of the roadway.

- Storage location planning

Storage location planning is to attaching storage location codes to goods. A clear storage location code can help warehouse operators quickly find the location of product inventory.

- Inventory optimization

When an enterprise has a wide variety of inventories, a wide disparity of unit prices, and different stocks, the ABC classification method can be used to distinguish the primary and secondary, grasp the key points, and treat them differently, making inventory control more convenient and effective.

The basic principle of ABC management method: classify enterprise inventory (materials, work-in-progress, finished products) according to their importance, value, capital occupation or consumption quantity, etc.

Category A commodities are also known as fast-moving consumer goods. They have the characteristics of high sales volume, fast turnover, and a high proportion of monthly delivery days. They are suitable for storage and picking areas close to the review area, and are also the best picking areas for the entire warehouse region, thereby improving overall delivery efficiency. At the same time, it is also the area with the highest and most concentrated picking frequency in the whole warehouse. More orders can be picked under the same picking path, so it is also the core area for the whole warehouse to carry out transaction inventory.

Category C commodities are slow-moving or unsalable products with very low shipment volume and frequency. Because these commodities do not change or change little throughout the year, we can store such commodities at the back end of the warehouse area for inventory is also a relatively low priority.

Category B products are products with relatively few shipments and low shipment frequency. The storage location of such commodities is second only to the warehouse area of Class A commodities, and is relatively close to the operation areas such as distribution and review. Picking frequency and location are between AC.

- Inventory consolidation optimization

Inventory consolidation strategy:

1) Consolidate the same sku into the same location as much as possible to avoid excessive dispersion and make the picking area more concentrated;

2) Consolidate SKUs with a relatively small total inventory (1-3) to maximize the use of storage space, but pay attention to controlling the mixing of storage locations.

- Order wave and picking optimization

a. Wave grouping optimization

b. Picking principle

The side-by-side sorting in aggregated picking is suitable for e-commerce companies with small commodities, such as clothing, cosmetics, trinkets and other e-commerce enterprises. The sorting operation can be completed synchronously in the aggregated picking process, thereby saving money. Space and personnel for sowing and distribution.

One thing to note is that whether it is picking first and then sorting or sorting while picking, pay attention to the number of grids of the picking cart and the planting wall and the maximum upper limit of the order in the aggregated picking list, otherwise it will lead to order overflow.

- Picking tool optimization

Picking tools are mainly divided into paper picking and PDA picking.

Traditional picking by face list: high picking efficiency, relatively low accuracy, and inability to synchronize inventory in real time, relying on old employees who are familiar with the placement of goods in the warehouse, and newcomers are slow to get started. PDA picking can take into account the efficiency and accuracy of picking, realize real-time synchronization of inventory, and automatically prompt the delivery staff to select the type and quantity of the specified goods in the specified configuration.

So what are the advantages of e-commerce racks?

First, the direct advantage:

- E-commerce racks can centrally store goods and reduce warehouse area;

- Make full use of the height of the warehouse to increase the storage density of goods;

- The width and direction of the passage in the warehouse can be reasonably planned to improve the utilization rate of the warehouse;

- It can reduce the capital investment of warehouse land occupation;

- Reduce storage and storage costs for large e-commerce sellers.

Second, indirect advantages:

- E-commerce racks can improve work efficiency and reduce human resource costs;

- Increase the overall profit margin and enhance the price competitiveness;

- The item number stored in the rack can be accurately positioned for easy search;

- Cooperate with the electronic label and warehouse management system to record the accurate delivery and storage of items, and speed up the delivery speed.