The warehouse is a space that comprises multiple different types of stuff that need to be arranged very carefully and accessed when needed. Hence, when it comes to choosing the warehouse racking there are various aspects that need to be considered.

This guide below features a detailed insight into the right type of racking for warehouses and all the related important information. So, let’s read below.

Types Of Warehouse Racking You Can Buy

Different types of racking systems may be suitable for a warehouse, however, some of these types are discussed below:

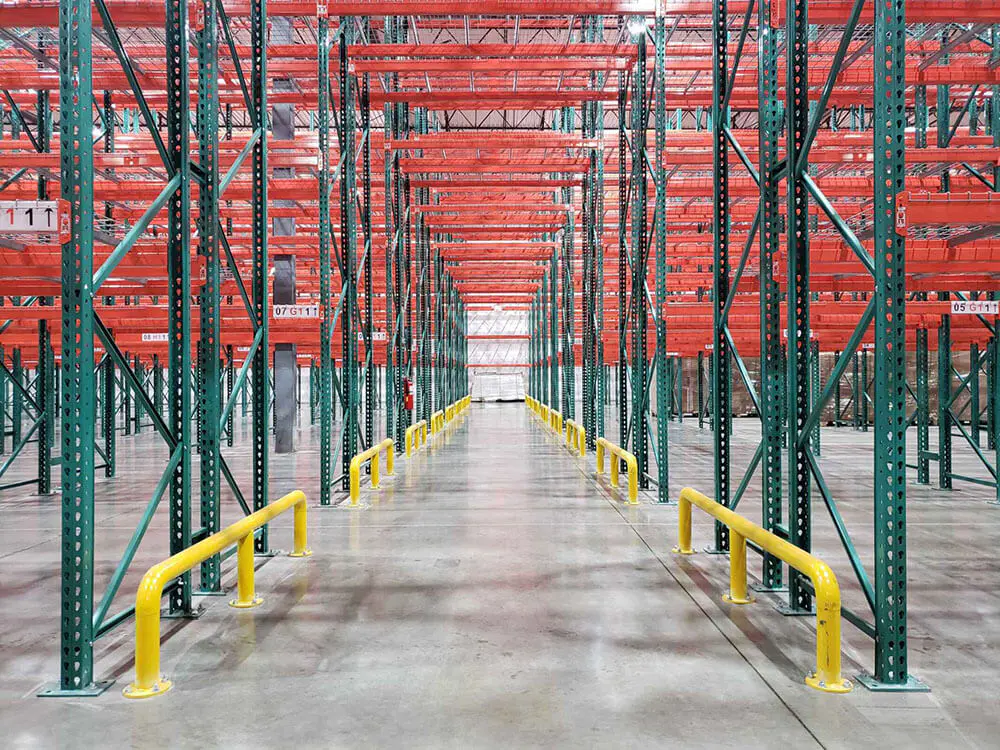

1. Pallet racking

You can consider buying pallet racking for warehouses as it comprises a storage system that helps to store the materials on pallets. It is an efficient method of storing material and allows the use of space smartly. The best part is that this type of racking system allows access to individual pallets.

Pallet racking offers a suitable option for warehouses where there is a wide variety of goods that can be stored in a flexible manner.

2. Cantilever racking

Cantilever racking comprises arms that extend from the central column. These racks offer support to items that are bulky and long like pipes and metal sheets. These racks are suitable for storing items that are equipped with different sizes and lengths and are quite popular in the construction industry.

3. Drive-in racking

The drive-in racking system is designed to cater to high-density storage, this is accessed by forklifts, and the pallets are filled with the stuff using it. The drive-in racking storage system uses the LIFO method and is suitable for storing a high volume of similar products.

4. Push-back racking

The push-back racking system comprises nested cards that can move along with the inclined rails. This method allows multiple pallets to be stored in one lane. As soon as a new pallet is loaded the existing pallets are pushed back. It is also suitable for high-density storage.

5. Mezzanine flooring

Mezzanine flooring is an elevated system of flooring that is between the main building floors and offers a space for storage. It helps to make use of storage space without expanding the building area. It is ideally suitable for using the vertical space present in the warehouse and is an unaffordable technique of storage.

Assessing Your Storage Needs Before Buying Pallet Racking

Before you invest in a racking system it is very important to assess your storage requirements so that you can opt for the right racking system which ensures sufficient storage space and ease. Some of the ways to assess your storage needs are discussed below:

· Evaluating warehouse space and layout

The assessment of the floor space is very important, you must know how much floor space you have and what is the ceiling height. If you are able to assess these two aspects you will be able to choose a racking system that goes with the overall layout of your warehouse.

The selection of a racking system that fits your space is very important so that you can safely and efficiently move the goods and equipment placed in the racks.

· Types of goods to be stored

It is also very important to assess the type of goods you need to store in the racking system. This will require assessing the size and shape of the items so that you can choose the racking system accordingly.

Every type of racking system is not suitable for every type of item, for instance, the pallet racking is suitable for palletized things and for long items, the cantilever racking is better.

· Load requirements and weight capacities

The weight of the goods you wish to store must be considered, the amount of load a rack may hold varies. Hence, you should consider the weight before you opt for the racking system and choose a relevant rack, sometimes overloading the racks may lead to damage.

· Accessibility and retrieval frequency

The accessibility factor is very important to assess for choosing a racking system. You must have an idea of how often you will need to access the different items and how frequently you will need them. For instance, for quick access, you will need pallet racking and for high-density storage, you will need drive-in racking.

Factors to Consider When Buying Warehouse Racking

When choosing a racking system for your warehouse, there are some important factors that you must consider and these are discussed below:

· Durability and material quality

The construction of the racking system and the quality of the material used in its making are very important. The racks that are made using high-quality and durable materials are meant to last longer and even resist wear and tear. Also, you must have a look at the finishing and coating in order to ensure added protection against the damage. Galvanized racks are usually more suitable for outdoor use.

· Scalability and flexibility

The future expansion is also a matter to consider when choosing a racking system. You must analyze the fact that with the passage of time when our inventory grows, the racking system will be able to cater to it. In short, the racking system must be adjustable and flexible enough to meet the scalability requirements in the future.

· Safety features and compliance with regulations

It is very important to ensure that the racking system you have chosen meets the safety standards and regulations. Always look for different features like the mechanism for locking, and guard rails and check if the local safety regulations are met or not by the chosen racking system.

· Cost considerations and budget constraints

The overall cost of the racking system which comprises the cost of installation as well as the cost of maintenance, both need to be assessed. Always conduct a survey to assess the price as every racking system is priced differently. For instance, pallet racking price and cantilever racking prices vary due to their making and structure. You must check if a particular racking system falls under your budget or not.

Choosing the Right Supplier For Buying Warehouse Racking

There are various ways to buy racking, you can choose to visit the suppliers or you can even buy pallet racking online for warehouses. Some of these aspects to consider when buying the racking for the warehouse are as follows:

· Reputation and reviews

Choosing the right pallet racking supplier requires an assessment of the supplier’s reputation. You can always assess the reputation of the supplier by going through the customer reviews on their website or official social media pages.

It is always recommended to look for suppliers that have a strong track record of customer satisfaction. Always go through the reviews online very carefully and check for any red flags. Also, if possible try to take personal feedback from the previous customers.

· Customization options

Warehouses may have different layouts and requirements for the racking system. Hence, many warehouses may need customized racking and for this, you must inquire if the supplier is ready to offer a customized racking system.

Customized racks offer a storage solution that fits the layout of every type of warehouse and even caters to different storage requirements. The customization of the racking comprises having your choice of dimensions, load capacity, and other additional features.

· After-sales service and support

Carry out an evaluation of their after-sales service and support. You must choose a supplier that offers after-sales service which includes technical support, repairs, and maintenance. A supplier that offers to back their products with their support can be considered a reliable one.

· Delivery and installation services

Ensure that the supplier offers delivery and racking installation services for the racking system. It is very important for the racking system to be installed by professionals in order to ensure that they are safe and functional.

Common Mistakes to Avoid While Buying Warehouse Racking

When you buy a warehouse racking, some of the mistakes that you must avoid are as follows:

· Overloading racking systems

Never overload the racking systems more than their capacity. If you end up placing a lot of weight on the racking system, its structure may fail which leads to damage of the goods, accidental injuries, and many other issues. Always ensure that the specified weight limits are referred to when loading goods on the racks.

· Ignoring safety regulations

Non-compliance with the safety regulations is also a very common mistake which may result in fines and accidents. It is suggested to always ensure that the racking system you are choosing is designed and manufactured in a way that meets international regulations.

· Poor space planning and layout

The space in the warehouse must be utilized appropriately, if you do not use the space efficiently it leads to a reduction in storage capacity and bottlenecks in the workflow. Always make sure that you have conducted a space analysis before investing in a racking system. Make sure to consider aspects like the width of the aisle, forklift access, and the need for future expansion.

· Neglecting regular maintenance

The maintenance of the racking system must be considered on a timely basis. In cases where no timely inspections are performed the risk of failure of the racking system may increase as with time everything tends to wear out.

Make sure you have developed a routine schedule for maintaining the racking system and in case there are any issues make sure to address them timely.

Buying Pallet Racks From China VS Buying Pallet Racks From Other Countries

When it comes to assessing pallet racking from China or other countries there are several factors that must be assessed. When you buy racking from China you attain cost savings and also versatile options, China offers a wide production capacity and low cost of manufacturing.

However, the quality may vary and the time for shipping may cause a challenge. Moreover, there are communication barriers too when sourcing the pallet racking from China. On the other hand, when you source pallet racking from other countries the cost may be higher and the customization features can be fewer, though you can get a better quality. However, it is very important to balance everything.

Therefore, no matter whether you are buying pallet racking from China or any other country you must ensure that quality, cost, and regulatory compliance are well balanced.

What is the process of buying pallet racks From a Chinese Manufacturer?

The process of buying pallet racking from a Chinese manufacturer consists of the following steps as given below:

- The first stage is a selection of suppliers, you can gather a list of suppliers from various online platforms like Alibaba and Global sources, or you can take references from people in the surroundings. At this stage, you will be analyzing their reputation, feedback, and certifications.

- Reach out to the shortlisted suppliers and communicate with them, ask about their products, take quotations, and assess how responsive they are.

- Conduct a verification of the products, and assess their quality, you can even request samples.

- Negotiate the terms of payment, schedules for delivery, and customization requirements you may have.

- Place your order and document everything appropriately, make sure to discuss the mode of payment and shipping terms beforehand.

- Coordinate with the logistics and keep track of your shipment so that you can stay updated with the status of your order.

Why Choose Mracking for Buying Warehouse Racking?

Are you looking for a warehouse storage solution and need the right racking system? Mracking offers the finest quality racking systems of various types. The quality, cost, and durability of these racking systems are commendable. The best part is that these racking systems are equipped with versatility and hence tend to hold various storage items of all types. Mracking offers customized racking solutions based on your requirements. The entire process of manufacturing the racking system is equipped with a consistent check and balance for the quality ensuring that there is no loophole left behind. So, get in touch with Mracking today and order the right type of racking system for your warehouse.