With the rapid development of the modern warehousing and logistics industry, the types of storage racks have become more and more, and major enterprises can choose the right rack according to the actual situation and actual needs of their respective warehouses. In a wide variety of storage racks, the mezzanine racking can be said to be the most widely used special type of rack, but also it is a new type of rack commonly used in warehouses. Because of its strong load-bearing capacity, high stability, compact unit mode, large space utilization, and convenient access, it has been favored by major enterprises. As far as the Mracking manufacturers are concerned, we still recommend enterprises use the mezzanine racks.

What is Mezzanine Racking?

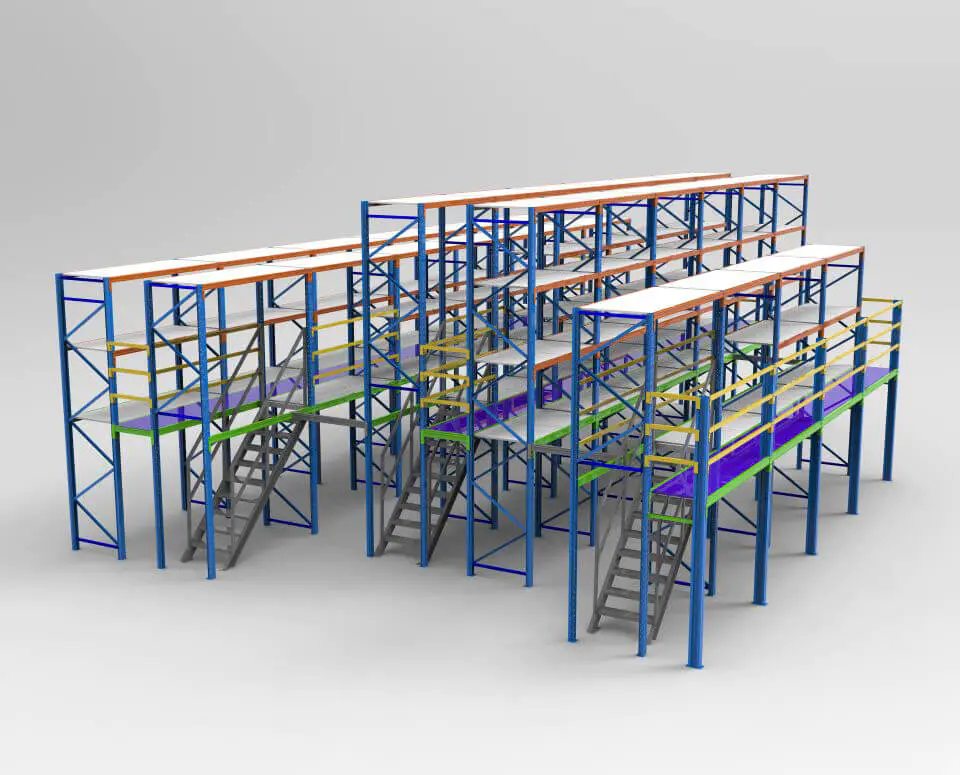

It is a rack as a support point, at a specific height laid with an access floor, guardrail, pedestrian stairs, goods slide, ladder, hydraulic lifting platform, etc., so as to form two or more layers of storage units, in order to save space and efficient use of the warehouse, improve the operational efficiency of a kind of rack, and the floor panel will generally choose cold-rolled steel floor, patterned steel floor or steel grating floor three kinds of steel materials.

Advantage one: space utilization

The Mezzanine racking system is an intermediate attic built on top of an existing work site or existing racking, with the aim of increasing storage space.

Advantage two: material

Generally is the choice of three materials, namely steel grating floor, patterned steel floor, and cold-rolled steel floor. The most used cold-rolled steel floor plate, the biggest advantage of this material is good overall performance, uniform load-bearing performance, strong load-bearing capacity, high standard of accuracy, flat surface, and also has easy lock performance.

Advantage three: diversified types

There are many types to choose from, and it is easy to match the lighting system, which is quite convenient for access and management.

Advantage four: convenient operation

The height of the top rack is generally set at 2m; the floor spacing is 2.3m-2.8m; the load capacity of each unit rack is 600kg, which is designed for the convenience of staff operation.

Advantage five: flexibility and mobility

The biggest advantage is that it can be relocated and re-upgraded. It can be changed according to the size of the leased warehouse and goods, and it can be equipped with elevators, inlets and isolation nets as needed.

Advantage six: improve the quality of storage

Dustproof, anti-theft, moisture-proof and anti-damage measures are adopted, so the storage quality of materials can be improved.

Advantage seven: structure

Load-bearing capacity is very strong, and also not easy to deformation, the structure is also extremely stable and diversified, and disassembly and assembly are more convenient and quick.

Advantage eight: cargo classification

The goods are easy to count, classify, measure, etc. It can also be used together with parts boxes and crates to make the classification of goods clearer and more explicit.

Mezzanine racks have two types of layout, namely: a single rack combination and a high and low combination.

Single racks combination: When using a shelving product, we can choose any one of the three types of shelves, high, medium or light shelves, and this storage layout is very simple, only need to combine the shelves and the area of the site can be reasonably planned for installation.

High and low racks combination: This combination can also be divided into high shelves combination and low shelves combination. One type is a separate combination, that is, high warehouse shelves and low shelves each have an area. This installation mode is also convenient for the classification of storage goods; another category is the placement of light or medium-sized low shelves under the high shelves, this mode of operation is intended to make full use of storage space.

The difference between single racks combination and high and low racks combination.

Single rack combination: when the warehouse racks are used alone, only simple storage operations can be carried out.

Combined racks: Combined shelves not only have storage capacity but also have better use of space, to expand the role of storage, of course, this combination of racks is also a storage business that must take the layout of the way.

When we choose this kind of rack, the most important thing is to consider the choice of steel material. The use of steel with high corrosion resistance is most appropriate. Mracking using steel are generally selected to add the addition of Al, Mg, Ni, Cr and other alloys of special steel, such steel materials can further improve the corrosion resistance of steel. At the same time, the surface treatment of the anti-corrosion rack plays a very important role in the entire production process, such as pre-machining treatment, processing equipment debugging, post-machining treatment, the surface needs to go through passivation treatment, but also the need for anti-corrosion coating special process treatment, Mracking are generally surface degreasing, passivation, electrostatic spraying, and the coating thickness can be as high as 100-200 microns. Such a layer of dense protective film, not only played a role in isolating the role of external pollutants but also played the role of adsorption of the coating. For the problem of sealing the coating, Mracking also uses a high corrosion-resistant coating secondary coating process, greatly improving the sealing of the coating, not only that, but Mracking in the installation process also provides anti-corrosion supporting accessories and the use of daily operation and maintenance, so as to ensure that the storage rack corrosion resistance performance.

Hey friend, see this is the end, I hope this article can bring you some help, welcome to follow me, you can learn more about the rack. Finally, we also welcome to consult Mracking.