Shelving or racking is important in any warehouse. This is because warehouses use shelves or racks to store unit loads, materials or goods that either come into the warehouse or are going out of the warehouse.

Since the type of storage structure to have in a warehouse mainly depends on the warehouse type, it is expected that in a warehouse that requires a storage structure for long, heavy and bulky materials such as lumber, plywood, timber, steel tubes, pipes, and other types of such materials, then such warehouse needs a type of special shelving to store these materials. The most appropriate shelving for such a warehouse is the cantilever shelving.

If you are reading this, it means you need every bit of information you can get about cantilever shelving or you are in search of a special type of shelving for long, bulky and heavy materials. This article will espouse what cantilever shelving is, its components, types, uses, advantages, disadvantages, regulations, and safety measures.

What to Know About Cantilever Shelving

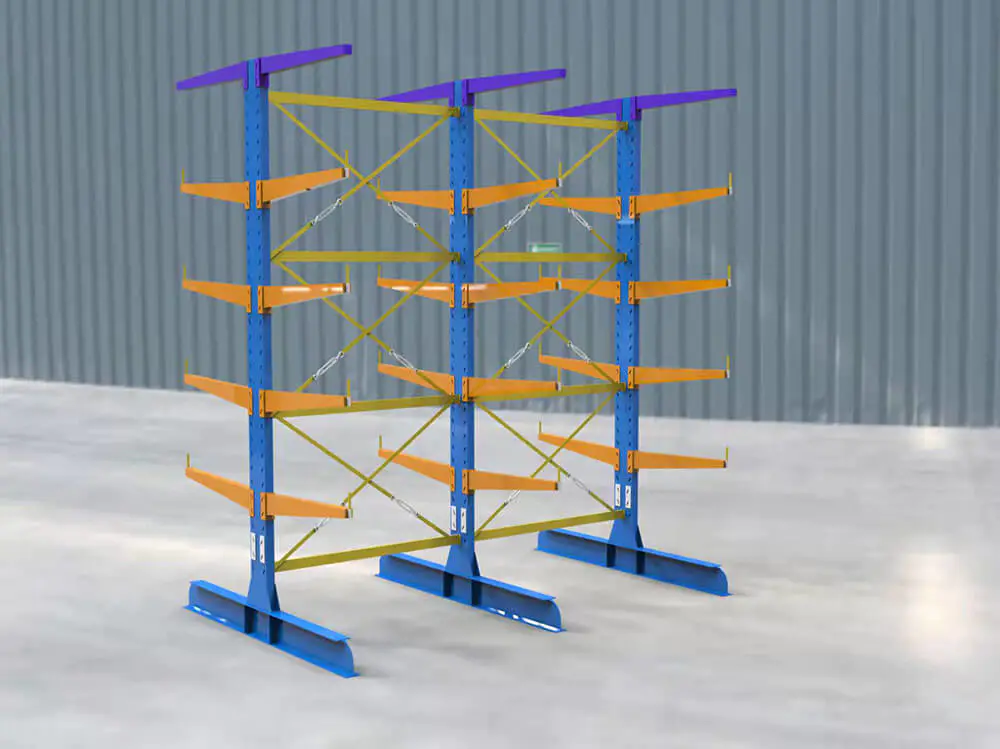

A cantilever shelving is a storage structure with racks suitable for storing bulky materials with long lengths. Cantilever structures have vertical racks connected to a horizontal upright column that make it look like the letter “H.” The racks of a cantilever shelving structure extend a long length from the horizontal structure that holds it. The racks serve as the arms of a cantilever shelf. A cantilever shelving racks can either be single or double-sided, made of steel and sturdy enough to hold any bulky materials.

One benefit of the cantilever shelving is that the racks have no vertical obstructions. It means that there is a free space in the front columns for placing the materials on the racks. Because of the structure of the cantilever shelving, you can easily load and unload any material and can adjust the rack to the suited size of the type and length of material you want to store on the racks.

The structure is also open enough that it makes the stored visible for inventory taking, and easily seen when storing materials, thereby making the loading and unloading of material go faster and more efficiently.

To store the long and bulky materials on the racks, you need to use a forklift. A cantilever shelving rack is vertically long enough to hold any length and size of materials, especially vertical materials.

Components of Cantilever Shelving

Typically, a cantilever shelf consists of columns, arms, brace frames, bases, and decking,

Columns

A cantilever shelving structure has a column with an upright structure and serves as the component that connects to the base. Further, the upright columns connect to the arms of the cantilever shelf. Whether in a single or double-sided shelving, you require an upright column to connect to the arms. This is because the upright column has holes that hold the arms tightly and form the storage levels of the shelf.

Base

Think of the base as the stabilizer component of a cantilever shelf structure. The base holds the rack to the floor to make it sturdier and able to withstand any density of load stored on it. A cantilever shelving structure typically consists of central base arms. This allows for tweaking of the cantilever shelving arm to adjust its size, structure, and length to the kind of materials/unit load you want to store. The base also connects to the upright columns and holds it in place so that when the upright columns connect to the arms, they hold firm.

Arms

The arms serve as the cantilever shelving racks on which you store materials or unit loads. It connects to the upright columns and shoots out. You connect the arm vertically to the upright columns in varied heights as you desire based on the load density you want each rack to hold. Most cantilever shelving arms are adjustable. You can set its structure to match that of the type of material you want to store. Also, you can configure the length of the arm to the size suitable to hold the type of material you want to store.

Brace frames

The brace frames are the structure that holds the upright columns. It is usually attached to the back of the cantilever shelving structure and connected to the upright columns providing a support system by holding the upright columns tightly. It is important to note that the sturdier the brace frames, the more load density the shelves can hold without crumbling structurally.

Decking

The decking is an optional structure of the cantilever shelving that is based on the type of shelving structure you want. That is, you may opt not to have a decking. What a decking does is give another storage space to add to the cantilever shelf.

Cantilever Shelving configuration

Depending on the structure of the arm, a cantilever shelving structure can either be single-sized or double-sized.

Single-Sided Configuration

A single-sided cantilever shelving configuration is usually backed up against the wall. Typically, the base behind the arm structure provides the balance for the racks. Unlike the double-sided configuration, you can only access the single-sided configuration from one opening.

Double-Sized Configuration

A double-sized cantilever configuration means that there is an opening from either side of the racks which you can use for storage of materials. There is a central column and there are openings on either side of the central column. Thus, you can access and store materials from either side.

Types of Cantilever Shelving

Depending on the type of warehouse, the type of material you want to store, and the load density, there is a variety of cantilever shelving structures that you can choose from. Because cantilever shelving are almost structurally identical, the different types of cantilever shelving structures lie with the differences in the rack. The different types of cantilever shelving include the following:

Structural Cantilever Rack

This is a cantilever structure with sturdy racks made of hot-rolled steel. The sturdy structure makes it suitable for loads with heavy weight and higher density loads. Because of the material used to make it, it lasts longer than other types of cantilever shelving, however it is more expensive to build.

Roll-formed Cantilever Rack

While the structural cantilever rack is made with hot-rolled steel, this type of cantilever shelving is made with cold-rolled steel. However, because the steel is cold-rolled, it is lighter than the hot-rolled cantilever rack structure.

Also, the structure of the beam pin connectors does not have bolts. That does not mean they are not durable or cannot store materials. It only means that they cannot hold the load density a hot rolled cantilever shelving racks can hold. But, it is important to note that because they are lighter, it means they are easily adjustable to fit with the type of material you want to store.

Further, they are easier to install and cost less than the hot-rolled structure. However, one major disadvantage of the cold rolled shelving rack is that forklifts can easily destroy it if you are not careful with it and it makes an impact when loading or unloading materials.

Conventional Cantilever Racking

This type of cantilever racking is a one-sided cantilever structure with wide openings. They are easily adjustable and can accommodate materials of any length. It is also easier to access it with a forklift or loading trucks to load and unload materials.

Free Path Cantilever Racking:

This is a type of double-sided cantilever racking that is placed beside one another. To access each cantilever, there is a wide aisle between the cantilever shelving.

Light Duty Cantilever Rack:

This type of cantilever shelving structure is primarily for manual loading and unloading of materials. It cannot hold heavy materials which maximally exceed 5,000kg, depending on the structure. Most light-duty racks cannot hold up to that.

Importance of Cantilever Shelving

Typically, when you have long and heavy loads to store, especially in a warehouse or manufacturing floor, you need a structure to keep these materials. This makes inventory easier, it is easy to also take these materials whenever you want to use them or just take them out if the warehouse is for storage of finished products. Other types of racking structures are mostly not structurally fit to hold such types of materials and thus having a cantilever shelving structure is important.

What’s more, is that you can use cantilevered shelving in a big industry or a small industry. It also does not matter whether the material you want to store is raw, finished, or under processing. The design of a cantilever shelving structure makes it suitable to hold such materials. They have sturdy structures that allow them to hold heavy materials. Some cantilever structures can hold as much as 10000 kg of materials. Cantilever arms can hold up to 2,000kg each. Even the lightweight cantilever structure – the light-duty rack – can still hold 5,000 lbs of heavy materials.

Cantilever shelving structures are also long. The length of the arms can go horizontally 30 feet tall depending on your warehouse space. Although typical cantilever racks are usually 15 feet tall, that is still a good storage height for materials. It means you can have more than five vertical arms horizontally connected to the upright columns and store long materials of at least 1,000kg on each arm.

Furthermore, you can save a large storage space with a cantilever shelving structure. You can then use this saved space for other important things like constructing a mezzanine structure for an office space.

Advantages and Disadvantages of Cantilever Shelving

Are There Any Advantages to Opting for Cantilever Shelving?

Cantilever shelving is your go-to storage system if you are looking to store long and bulky materials with high load density and save warehouse storage space at the same time. They also help boost the storage capacity of your warehouse and allow you to have a well-organized storage system.

1. You can easily design and install a cantilever shelving.

2. Cantilever shelving structures are movable from one location to another, especially light shelving.

3. The arms of the cantilever Shelving are easily adjustable and can adapt to hold materials of any length and size.

4. Cantilever shelvings are cost-effective. For example, the cold rolled cantilever racks are less expensive.

5. Cantilever racks can hold any type of load.

6. It has a wide open space that is easily accessible.

7. The double-sided cantilever shelving allows you to access and store materials on both sides of the racks.

8. It helps you store materials/products that may otherwise be awkward in other types of racking

9. It allows you to maximize your warehouse floor space.

10. You may choose to implement a guided aisle system for your cantilever shelving which means that the runs are close to one another, and you eliminate the unnecessary space taken by utilizing a wide aisle system.

11. You can position the racks of cantilever shelving high enough that you maximize the cube space of your warehouse floor.

12. Cantilever shelving is more visible and organized. You can see your stored materials even from a distance.

13. They reduce hazard risks in the warehouse. This is because they provide a storage option for materials like long aluminum sheets which may otherwise be dangerous if you opt for a floor-stacking storage option for them.

14. They do not have columns or any type of support system in the front row and so do not require any special kind of forklift to load and unload the racks.

15. They are durable.

16. Cantilever racks are sturdy enough to hold about 40,000 lbs of materials.

What Are the Disadvantages of Cantilever Shelving?

Although the cantilever shelving storage system is a highly efficient storage system, there are some demerits you should know about when you opt to install one.

1. They are not suitable for all industries and warehouses. You need to know the specific kind of material you want to store before you can opt for installing a cantilever shelving

2. There is no one-fit- all cantilever structure. You need to design it to fit the type of material you want to store. This may mean that you always have to adjust the structure to the model of what you are storing. This may take time and increase maintenance costs.

3. Cantilever racks are more expensive than other racking structures.

4. If you are storing materials that are 48”× 40” or shorter in size, then the cantilever shelving structure is not suitable for you. This is because the design of cantilever shelving is for long and bulky materials, not the traditional pallets.

5. If you do not have a large warehouse floor, then it may be hard for you to use cantilever shelving and still have enough storage space. This is because cantilever shelving takes up much storage space as they require more space for aisles in order to use forklifts to load and unload the racks.

6. Defective racks are highly hazardous and the structure can easily collapse upon repeated impacts from forklifts. When the structure collapses, it may damage your products or stored materials.

7. Structures like the cold rolled steel are light. Thus, forklifts can easily damage them.

Regulations Guiding Cantilever Use

Cantilever structures require seismic testing. The risk of earthquakes damaging the structure is high if the structure is not sturdy enough. Thus, cantilever shelving structures should be designed to withstand seismic activities that may cause damage to it.

Considering this, cantilever shelving structures require a seismic permit before you can use them. For example, in the US, the Building Seismic Safety Council and the Federal Emergency Agency regulate the use of Cantilever shelving structures. You will need to obtain a permit from these agencies before you can begin to use cantilever structures.

In China, cantilever manufacturers need to get CE certification to import their structures. Also, to sell in China, they need to obtain certificates that show that the structure is good to use. To get this certification, the cantilever shelving must pass different tests and safety directives. It must pass regulations and must conform to set guidelines.

What You Should Consider When Opt for Cantilever Shelving

Type of Material: The type of material you want to store is important to consider before you opt for a cantilever shelving. If you want to store materials with long lengths and are bulky, then cantilever shelving is your best storage option. However, if you are looking to store traditional palletized materials that are 48″× 40″ or shorter in size then you should opt for other racking structures.

Budget: Your budget determines which type of cantilever shelving structure you will get. Some are more expensive than others. Also, if it is not especially necessary, then you may not need to opt for cantilever shelving because they are more expensive than regular palletized storage options.

Weight of Materials: the weight of materials you want to store will determine if you should go for the structural cantilever rack or the roll formed cantilever rack. If your load is heavier and bulkier, then it is better to opt for the structural cantilever rack. This is because it is made of hot rolled steel and is sturdier than the roll formed structure which is made of cold rolled steel.

Warehouse Space: Cantilever structures, although they give you more storage space and a well-organized storage system for long, awkward and bulky materials, they still take up a lot of warehouse space because they require aisles on different sides for easier access. Thus, you should consider your warehouse floor space to know if to opt for the one sided or two sided rack. If you have enough floor space, then you can opt for the two sided rack. The wide aisle space allows you to access your stored materials from both sides of the rack. However, if you have limited warehouse floor space, you may opt for the single sided racks. This is because you can back them against the wall while having more storage space in the warehouse. Furthermore, the height of your warehouse building determines the height of the cantilever racks.

Conclusion

Cantilever shelving offers you an efficient storage solution for lengthy and bulky materials that may otherwise be awkward on other racking structures. It also provides a safer storage option than having these materials on the floor of the warehouse. Cantilever shelving structures are easier to use, faster and cost effective.