Every day, there arises an increasing need for warehouse storage options. More warehouses have a higher load density than their space capacity can allow. Also, warehouse owners often are unsure of which warehouse racking structure option is best suited for storage in their facility.

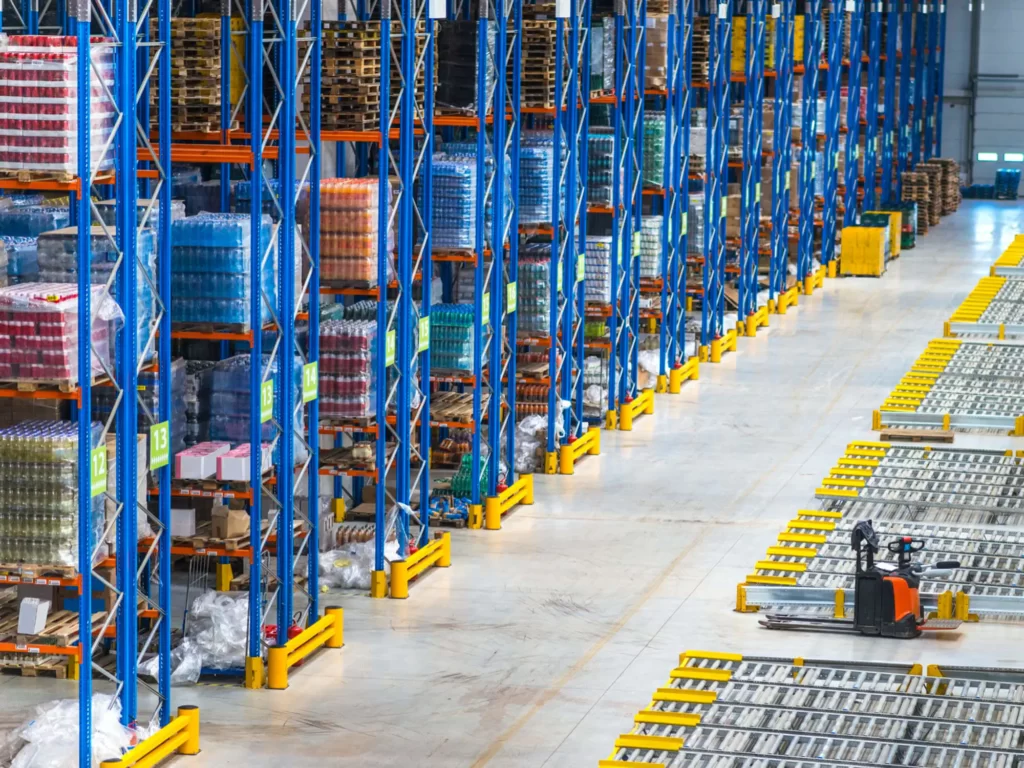

A warehouse rack is a type of industrial shelf. It allows for the storage of warehouse loads, boxes, or pallets before moving them out of the facility. These types of warehouse industrial racking are typically made of metals. Depending on the type of structure employed, warehouse racking systems typically have multiple levels, in horizontal rows and you place the goods on each level.

Of the types of storage structures, the most typical is the double deep pallet racking and standard selective racking. There are different factors to consider before making a choice on which storage structure to choose from. You need to consider the cost of installation, the load density, the structure, your warehouse space, the forklifts, and many other industrial factors. Thus, it is crucial to have sufficient information on what double-deep pallet racking is, what selective pallet racking is, the pros and cons of these two racking systems, and how they are different from each other.

What Is a Double Deep Pallet Rack

Double-deep pallet racking is a solution-oriented warehouse storage structure providing a substantial increase in pallet positions. It is a structure with two pallet racks stacked on two levels on top of one another and one pallet is placed behind another. The inner part of the pallet rack is called deep and the outer part is known as “shallow.”

Double deep pallet racks require a special forklift to access the second depth of the rack. It is commonly used in warehouse and retail stores with dry products or loads with longer shelf life.

By implementing double-deep pallet racking, you can effectively address storage load issues. You can achieve this by utilizing the ability to store pallets in two depths, thereby effectively optimizing your warehouse space.

Think of the combination of two selective racks, that is what a double pallet racking is. The setup of a double deep pallet is against a wall with two deep rows. The back-to-back pallet is then set up against another back-to-back pallet to achieve a double deep pallet. The setup is so there is enough space for more storage.

An Insight into Selective Pallet Racks

A selective pallet rack is a storage racking system where every side of the pallet racks is directly accessible from the aisle. It is also typically a one pallet rack structure shaped horizontally and vertically made of steel with wield trusses. Their beams are sturdy enough to withstand a high capacity of load.

A standard selective pallet rack looks like the everyday shelves in the homes. It allows for the storage of loads in any order that you want to store it and removes loads from any part of the pallet racks at the same time with the use of a lift truck.

Selective pallet racking is the most typical of all the pallet racking systems. It requires a larger warehouse space for the aisle because it has an opening from either side and so you can bring out any load you want from the pallet. That is, you can access every part of the pallet racking from the aisle. It doesn’t matter if it is the load you stored first or the one you stored last. You do not need to move a pallet just to access another pallet as one would in the double deep pallet racking.

Structural Comparison of Double Deep Pallet Racks and Selective Pallet Racks

There are different structures and components that make any pallet racking system suitable for use in a warehouse. These components include the beams, the frames, the uprights, forklifts, protectors, outriggers, and baseplates, among others.

Structure, Components, and Equipment of Double Deep Pallet Racks

A double-deep pallet racking is a type of adjustable pallet racking system. Components such as beams, frames, outriggers, baseplates, support bars, upright protectors make up a typical double deep pallet rack.

Frames: Double deep pallet racking is typically made up of two upright frames with diagonal braces and breastplates and tied together. For sturdier structures and higher load density, baseplates are welded to the upright frame.

Beams: The beams are for joining the frames together. Beams of a double deep pallet racking are horizontal and are to support the pallets.

Outrigger: In a double deep pallet racking, an outrigger can either extend out of the pallet or under the pallet.

Safety measures: It uses pallet backdrops, upright protectors, corner protectors, upright reinforcement protectors and side protectors for installation safety. These prevent pallets from falling, retain unit loads, protect the structure from the impacts of forklifts, and protect the uprights both external and internal.

Forklifts: Double deep pallets require special forklifts to load and unload loads in the pallet racks. You may either need a lift truck which can be a pantograph or non-pantograph, or an articulated forklift. You need these forklifts to reach the top part of the pallet racks which are not easily visible and the depth which can only be accessed with these forklifts.

Structure, Components, and Equipment of Selective Pallet Racks

Selective pallet racks are simpler to design and install. They do not require many accessories and components to achieve a simple structure. The essential components and equipment include an upright frame, a horizontal brace, and load beams to connect the upright frames. The load beams are also responsible for holding the pallets. The footplate is another crucial component. It is used to connect the upright frames.

A standard selective pallet rack is typically 5m in height and can hold a total storage load of 500 – 2000kg. You can use wired decking or bolted cross bars to support the pallets. It does not require the use of any special forklift for loading and unloading the pallets. A standard counterbalance forklift or any standard forklift is suitable for loading and unloading.

A standard selective pallet rack design is flexible. You can tweak it to match the type of load you want to store.

The Expected Cost of Double Deep Pallet Racks vs Selective Pallet Racks

There are different factors that come into play when determining the cost of pallet racking system. Most warehouse owners opt for pallet racking systems that are cost-effective, durable, sturdier and efficient. However, there is also the need to understand which pallet racking is appropriate for the warehouse. The type of pallet racking, weight capacity and height, also play an important role in the estimated cost of installing pallet racks in a warehouse.

Since cost-effectiveness is also a factor in determining the type of pallet racks to choose from, it is important to know the estimated cost of double deep pallet racks and that of standard selective pallet racks.

Double Deep Pallet Rack Cost

Although double-deep pallet racks increase storage capacity and allow for storage of high density and heavy loads, it is a little more expensive than other types of pallet racking systems. This is because double-deep pallet racks require special accessories and a special kind of forklift to load and unload pallets.

Also, it requires a specific warehouse building space and irregular rooms. Installing a double deep pallet rack itself is not very expensive, but when you factor in the special accessories and special forklift required, then the cost goes up. However, it is still cost-effective because it provides an additional storage space more than any other storage racking structure.

Selective Pallet Rack Cost

A selective pallet rack is easier to design and install. It is also cheaper than the double-deep pallet racks. A standard selective rack does not require any special forklift to load and unload unit loads from the racks. A standard counterbalance forklift is enough to load and unload pallets from the racks. If you do not have this, a lift truck is enough to load and unload from the racks.

However, selective pallet racks require a large warehouse space because it needs space for aisles on both sides of the pallet racks. Thus, it is more cost-effective when you have a large warehouse space.

FIFO vs LIFO Storage Systems

FIFO is an acronym for “first in, first out,” while LIFO is an acronym for “last in, last out.” FIFO and LIFO are inventory calculation systems that evaluate how loads are stored in pallet racks and the order in which they come out.

In FIFO, the first unit load to arrive at the warehouse goes into the pallets first and also comes out first when unloading the pallets. When taking the inventory of the warehouse storage, the first unit loads stored in the pallet racks are noted down and the section of the pallet is also noted down. When it is time to unload the pallet to take out such load type, you first take out the initial unit load that arrives at the warehouse.

You take out the last goods or unit load that arrive in the warehouse of the pallet racks first in the LIFO inventory system. This is because the storage of such goods is on the outside of the pallet racks aisle and you first take them out when unloading the pallets.

The LIFO system is appropriated with the double pallet racking system. This is because the double pallet racking system stores loads or goods at two depths. Typically, in this system, the inner depth becomes directly accessible after unloading the first depth. Thus, the last unit load that you load on the pallet racks comes out first when unloading the pallet racks.

This system is mostly appropriate for goods/loads that are similar. It eliminates the problem of unloading loads that are different from the ones directly accessible from the aisle but stored on the second depth of the double-deep pallet racks.

The FIFO system is mostly appropriate with the selective pallet racking. This is because all the pallet racks are directly accessible through the aisle existing on both sides of the racks. Thus, you can easily take out goods that come in first into the warehouse of the pallet racks since there is direct access to the racks.

Also, selective pallet racking accommodates the use of the LIFO system. It gives the warehouse manager the option to choose from either of the storage systems.

Advantages and Disadvantages of Double Deep Pallet Racks and Selective Pallet Racks

Advantages of Double Deep Pallet Racks

- A double deep pallet rack maximizes warehouse floor space. This is because the 2 back-to-back pallets can be accessed from the same aisle. Thus, there is no need for a big aisle space and you can use this space for more pallet racks

- The storage capacity of a double deep pallet rack is larger than most other pallet racking structures

- Double deep pallet rack holds high-density loads

- Access to pallets is easier with a double-deep pallet racking structure. Thus, loading and unloading loads is simpler and faster

- A double deep pallet rack is easily convertible to any other adjustable pallet racking system

- A double-deep pallet rack can hold any type of unit load regardless of the density or load type

- A double deep pallet rack is extendable to accommodate any type of unit load or allow for more storage space

- It is safe and easy to use

- It allows for the LIFO storage system which increases productivity, faster and leads to an increase in storage capacity

- Because the double deep pallet system allows for the LIFO storage system, it ensures that there is an accurate tracking of recent production costs and overall profit. This is because industries can keep track of their most recent loads/goods and calculate them against production and sale price

- It is a less expensive structure to install compared to other types of pallet racking structures

- It is the ideal pallet racking structure for goods with a long shelf life

Disadvantages of Double Deep Pallet Racks

- The LIFO storage systems may result in having expired goods in the warehouse. This is because the last goods in are not directly accessible and in a case where the same type of goods are stored in the same pallet racks, the first goods into the pallet depth may not be unloaded in time

- The use of the LIFO storage system may not be appropriate in all types of warehouses especially those that deal with goods that can expire

- The height of the structure is typically limited to 10 meters

- It is difficult to clearly see the second depth of the upper storage levels of the structure

- There is limited access to the second pallet row as there is only direct access to the double pallets from the front row. Thus to access the loads on the second pallet, you need to unload the loads on the first pallet

- It requires a special forklift to access rear pallets

Advantages of Standard Selective Pallet Racks

- A selective pallet racking is fast to load and unload loads

- There is direct access to loads from both sides of the aisle

- All parts of the pallets are visible

- It does not require a special forklift to load and unload loads

- You do not need to strictly follow the FIFO or LIFO storage system. You can use either system or both. This ensures that the first goods that come into the warehouse are also the first to leave thereby eliminating the possibility of expiration of goods in the warehouse

- It is easier to catalog loads

- It optimizes warehouse space as you can catalog the storage of loads based on the type of the load

- It does not require the use of special forklifts thereby saving money

- It is easier to maneuver forklifts because it has a wide aisle

- It is cost effective as it is easy to design and install

- A standard selective storage racking is adaptable to any warehouse flooring

- You can unload multiple loads from the pallet racks at once. This is because there is direct access to all parts of the racks from the aisle and so you can use multiple forklifts to unload the selected load of your choice

Disadvantages of Selective Pallet Racks

- Selective pallet racks are not as tall as other pallet racking

- It requires more warehouse floor space because it requires more space for aisle

- It is not most appropriate for high density loads

- Storage capacity is lesser compared to other racking systems

- It only uses 30 percent of the warehouse space for storage. The large percentage is reserved for the aisle

Differences between Double Deep Pallet Racks and Selective Pallet Racks

1. In a double deep pallet racking system, pallets are stored using a forklift. For a standard selected pallet racking system, you store unit loads either mechanically or manually. People store heavy loads using forklifts, while loads that are not heavy do not require using fork lifts.

2. Standard selective pallet racking system is not strict with FILO or FIFO. A standard selective pallet racking system allows you to store pallets or unit loads in any parts of the pallet racks and remove these loads from any part. On the other hand, a double deep pallet racking system strictly adhered to the FILO racking system. Double deep pallets only have one side out on the aisle which means that goods that go in first come out last.

3. Double deep pallet racking systems have higher load density capacity. The storage depth of a double deep pallet racking allows it to take in more unit loads than the standard selective pallet racking system.

4. A double deep pallet racking requires a use of a specialized telescopic forklift for loading and unloading of unit loads. Some may require the use of a forklift with specially designed pantographs. These pantographs will allow for reaching the second pallets for loading and unloading of unit loads.

5. A double deep pallet racking stores loads in two depths while a standard selective pallet racking stores in one single depth.

6. Standard selective pallet racking systems require a bigger warehouse space for aisle while a double deep pallet racking minimizes aisle spaces.

7. It is easier to use the FIFO racking system with the standard selective pallet racking, while the LIFO racking system is more appropriate with the double deep pallet racking.

8. A double deep pallet racking provides 50 percent more storage space than the selective pallet rack.

What to Consider When Selecting the Type of Racking System to Use

There are different things to consider when you want to select a racking system suitable for your warehouse needs. They include the following

1. Warehouse floor space: You should consider your warehouse floor space when selecting which to use between the double deep pallet racking and the selective pallet racking system. When your floor space is larger and you need to unload different multiple loads at the same time, then you should consider installing a selective pallet racking. However, when you have a limited floor space and have the same types of goods to store, then you may opt for the double deep pallet racking.

2. Type of loads: Loads that have limited shelf life typically require the FIFO storage system. Thus, it is best to opt for the standard selective pallet racking. Conversely, if you are storing heavy equipment or machinery, then you may need to opt for a sturdier pallet rack structure. In this department, double deep pallet racks have a higher capacity for heavy loads.

3. Weight and storage capacity: If you require a large storage capacity and high load density, then it is best you opt for the double deep pallet racking system.

4. Ergonomics: A selective pallet rack is more ergonomic than a double deep pallet racking. This is because you can unload multiple loads from the pallet racks at the same time when you are using a selective pallet rack. With a double deep pallet racking, you can only unload the second depth pallet loads after unloading the first pallet.

5. Height: You need to consider the visibility and accessibility to the height of pallet racks. The top of double deep pallet racking is not as visible and accessible as that of a selective pallet rack.

6. Budget: Both pallet rack systems are cost effective and not expensive. However, the selective pallet racking is easier and cheaper to install. This is because it does not require many accessories and they are simple designs that are adjustable and adaptable to any warehouse environment and floors. More so, double deep pallet racks require the use of special equipment, accessories and forklift and this increases the overall cost of using it.

7. Warehouse building: A double deep pallet rack typically is suitable for buildings that have angled walls, and are not suitable for every kind of building. Selective pallet racks do not require such special building features but typically need a large warehouse floor to maximize its use.

Conclusion: Which is Better or Which Should You Use?

As we have discussed, choosing between the double deep pallet racks and selective pallet racks is dependent on different factors. These factors include use, required storage, warehouse space, building type, and budget. Also, if you are running a retail store or an industrial warehouse, you need to carefully consider your options using the factors mentioned above. The storage and inventory system also plays a key role in choosing between the double deep pallet racks and selective pallet racks.

Nonetheless, it is important to note that regardless of your choice, these two types of racking systems are sturdy and safe to use. Their installations also make for easy use.