The tire industry is surely vast and dynamic. It is consistently gaining a rise in demand which ensures the industry’s bright future. The storage of tires with all the safety measures before dispatching them is yet another vast field. Proper stacking, controlling damages, monitoring temperature changes, and making arrangements accordingly is really important.

Therefore, to achieve all this, specialized racking solutions are there to help tire manufacturers to keep their products safe and secure. The tire storage rack helps in better managing the floor optimization and keeping the product safe in all weather conditions.

We will discuss tire storage solutions, tips and tricks to keep tires safe and secure, and the benefits of installing racking systems for tires in your warehouse. So, let’s get started!

Introduction to the Tire Industry

Just like any other industry, the COVID-19 pandemic had a great impact on the tire industry. The disruptions in the supply chain and lower demand throughout that time had a significant impact on the industry. This not only shut down the production units but also resulted in job losses. But things changed over time with global tire production of 1.8 billion units in 2020. Where Asian countries contributed 87% of the total world’s production.

According to the U.S Tire Manufacturing Association (USTMA), the tire shipment of 332.7 million units was sold in 2019 which decreased in 2022 to 332.0 million units. But the projected tire shipment of 334.2 million units is expected in 2023.

The global tire market had a worth of $240.5 billion in 2020 and is predicted to grow at a CAGR of 4.5% from 2021 to 2028. It will result in an estimated value of $342.5 billion by 2028.

Whereas, the tire recycling sector is experiencing growth due to the efforts of tire manufacturers and governments to decrease the environmental effects of tire waste. In 2019, the worldwide tire recycling industry had an estimated worth of $7.2 billion which is now anticipated to increase to $10.6 billion by 2027. This is all with a compound annual growth rate of 4.5% projected from 2020 to 2027.

It is noted that the facts and figures of the tire industry may vary with the unknown events and trends that can lead to the growth or loss of this industry. So, the manufacturers and storage keepers should adapt to new challenges and avail the opportunities as they arrive.

Tire Storage Racks for Efficient Storage Management

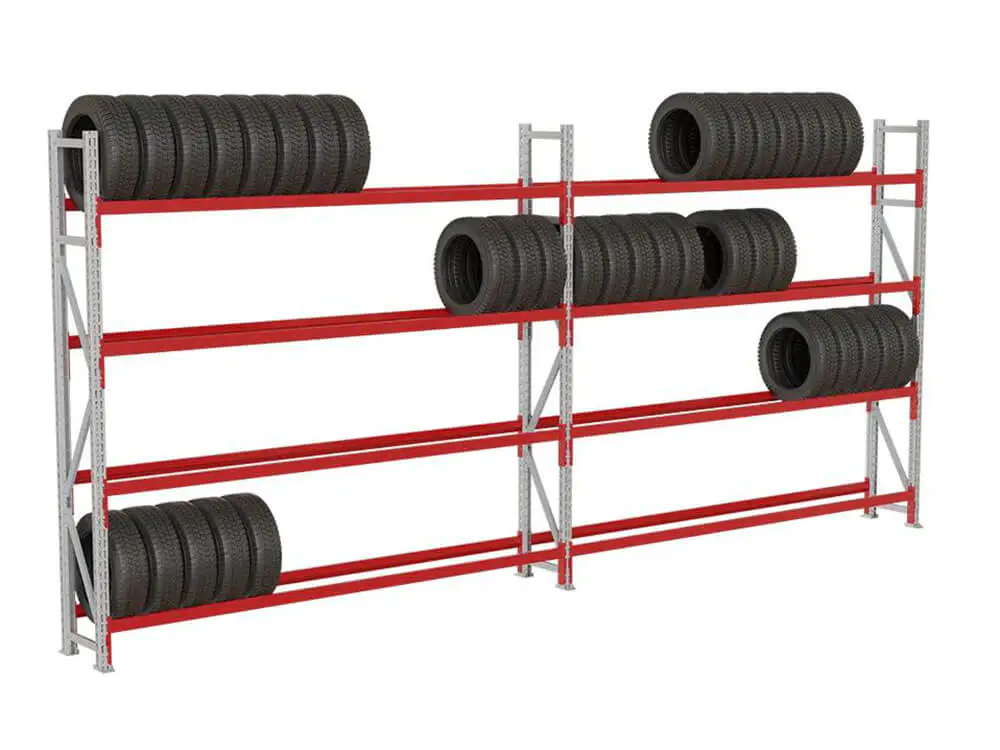

Tire storage racks come in a variety of forms to choose from. Every rack is designed as per the products’ demand and requirements. Because there are different sizes, shapes, forms, features, storage requirements for the tires, finish, material formation, and designs. Here are different types of tire storage racks that you might be keeping in your warehouse facility:

- Passenger tire racks

- Industrial tire racks

- Display tire racks

Passenger tire racks are usually used to store SUVs, trucks, and many other different types of passenger tires. Industrial tire racks are used to store tires of harvesters, bulldozers tires, wheel loaders, and shredders. Whereas, the display tire racks are used to store in small numbers just to give customers a hint about their purchase.

Now let’s dig into the racking solutions that are commonly used as tire storage and are efficiently being used in warehouse facilities.

1. Selective Pallet Racking System for Tire Storage

With an up growing number of tire production, there is a need to store the product in a useful and efficient way. Therefore, a selective pallet racking can bear up to 3000 kgs of load capacity and can be customized if more is needed. The selective pallet racking system is the perfect solution for keeping industrial tire racks and passenger tires.

Generally, selective pallet racks are used for heavy-duty purposes which makes it the best choice for industrial tire storage solutions. The main components used for this racking system are the beam and the frame. Therefore, the basic cost for this racking system belongs to steel material purchasing and then the processing costs will be charged.

2. Steel Boltless Racking System for Tire Storage

The boltless racking system is a great solution to keep passenger tires. It is a strong, economical, and effective way of keeping tires safe and secure within the warehouse facility. This racking system is made with steel material that provides a professional appearance as a whole and is priced the same as wooden racks.

A boltless racking system is all you need because it is durable and stays longer than usual ones. Also, these racking systems are super easy to install yet they are long-lasting. A boltless racking system means that there won’t be any nuts or bolts required for the installation. The frames are designed in such a manner that beams and uprights are fitted together that create a strong and secure bond.

3. Stackable Racks for Tire Storage

The tire rack that provides the best density along with easy handling is the one known as the stackable rack for tire storage. These racks are generally used when you need to store a large volume of tire batches. You can get your customizable stacking rack for your tire from a reliable manufacturer you trust.

Stackable racks can be easily disassembled when they might not be in use. This great feature makes this racking system much easier and is perfect for shipping racks. Stackable racks are constructed using simple designs that can be easily handled when you need to put away tires and retrieve them upon your requirement. Stackable racks for tire storage are not very expensive which is why your budget for the racking system cannot disrupt your overall costs.

Stackable racks provide an advantage in the long term period because of the fact that they can be stacked together and you can get a new storage solution. Stacking them together gives a three-dimensional storage solution. This is a quick and easy way to get storage when something urgent is needed to store in such way. You can also see how strong and secure the storage capacity will become.

Benefits of Using Tire Storage Racks

Tire storage solutions can be achieved with an excellent and organized system that can help you manage your warehouse operations get going efficiently and effectively. Tire racks have been used for a long time now because it provides exceptional storage solution. You can not only store different sizes of tires in these racks but also the varying weight and shapes can be stored easily.

But remember to keep the racks balanced and do not overstuff your products in those racks. The usage of tire racks is being loved by the users not just by the warehouse managers but also by the people use them for displaying purposes praise the racks.

Reliability, durability and cost-effectiveness are the key benefits these racks offer. So, here are some of the great benefits of using tire storage racks in your warehouse:

Versatility

When we talk about the racking system, versatility is the foremost thing that comes to mind. Hence, here is the same case with the tire storage racks as the racks have the ability to store products of different styles, designs, sizes, and shapes. The weight of the tires depends on the racking type. Some racks are designed for industrial tires and some are designed for passenger tires. Keep a record of the tires you will be storing in certain racks.

Racks are also made with different materials like stainless steel or steel, so they serve different purposes. But the main aim of these racks is to be constructed that last for a longer time and stays connected. Its durability will require minimum maintenance which eventually decreases the extra costs of maintaining the racks again and again.

There are two ways to keep the tire storage racks. One of them is to keep them floor-stand and the other is to wall-mount it. You can choose any of any which better serve your need and specifications. You can use half of the rack-style standing and other halves can be wall-mounted if you desire it.

Also, the floor-stand style comes with the folding technique so that whenever you are done with them, just fold them and put them aside easily. This versatile feature allows you to utilize your space and storage need well. Especially when you have limited space and you require urgent space extension, you can open up your stack racks and use them accordingly.

Easy Accessibility

Tire storage racks are constructed in simple designs because they require open spaces and ventilation to pass through. Usually, such racks are kept open from one side just like a standard racking-style design. This simple design allows you to simply put the tires when the shipment arrives and retrieve them when they need to be sent.

Tire racks are designed in such a manner that the sizes and shapes of certain tires fit regularly. Each tire specification should be met so that there will not be a mess and damage during loading or unloading the products. If racks are not properly designed and planned then there is a risk of damage and you cannot effectively store the tires.

Storage with a Showcase

Tire storage racks are simple yet they serve double benefit. They can be used to showcase tires when displaying them to the buyer or supplier. This way it can improve your warehouse outlook and you can get benefit from it. Also, racks are properly designed to help the warehouse operations to be run smoothly. If tires are kept on the ground they can get spoiled and the temperature beneath them might harm the surface of the tires. Therefore, you have to keep your racks updated and organized.

Tire display racks can be used to showcase various tire models in addition to saving space on the floor. If they are utilized as display racks, this helps buyers see what they are purchasing and makes it simpler to pick the proper tire. So, tire storage racks are a smart investment for businesses that want to save space and improve the shopping experience.

Secure and Safe Storage Solution

Tires that are stored directly on the floor can easily get damaged. Especially during the off-season and they might not be in the same condition again. However, tire storage racks offer a solution to this problem by providing a secure and supportive place to store tires until they’re needed again.

With the tire racking system, you are ensured that your product is safe and secure until they are dispatched. Care and skills are both still required for putting the tires into the racks.

Easy Installation

Tire storage racks require easy installation. For instance, a boltless racking system requires no bolts and nuts for the installation and therefore, it skips the need for much labor and saves costs. The assembly and disassembly processes are a hassle-free experience, which makes them easy to set up and maintain.

Factors to Consider When Choosing a Tire Storage Rack

Several factors can be considered when choosing a tire storage rack. But we have compiled the most important ones which will benefit you in your warehouse tire storage purchase.

Types of the Tire Being Stored

The type of tire you are storing must be kept under consideration while choosing a racking system. Because it might be greatly affected by the weather conditions or you may experience damages because of insufficient knowledge about the product.

The Size of the Tire

The size is another important factor that should be taken into account for tire storage racks. Figure out the sizes you will be requiring for a specific product. How many tire storage racks do you require for a certain size?

Calculate thoughtfully according to your product’s requirement and size description. Other than standard rack sizes, we would recommend you custom order your tire racks to get the desired storage solution.

Available Space

The space requirement is the important one here. Because optimum use of space will lead to efficient storage management. Check for the available space and install your racking system accordingly. Go for the maximum vertical space that you can manage. This will save you costs on purchasing or leasing extra space.

Weight Capacity

The weight capacity of the racks is according to the type of rack you choose from. It largely depends on the material you are choosing for the rack. Also, the weight or load of the product you want to store must be considered and then order your racks to get the perfect match for your tire storage need. Choosing a rack that is too small or the rack happens to fall due to some odd reason can lead to damages and warehouse inefficiency.

Material and Durability of the Rack

Material and durability are correlated because of many reasons. Tire storage racks can be made using different materials which may include steel, aluminum, wood, and plastic. Among all these materials, steel is the most durable one. It lasts for a longer time if you compare it with other materials.

But at the same time, it can be expensive and increases your costs. But remember, installation of racks can be a one-time procedure, and spending well on such a thing can save you from other damages and inconvenience.

Tips and Tricks for Tire Storage

There are tips and tricks to keep your tires as new as bought until they are sent ahead. So, read on and find out more details.

- Cleaning tires every day is important because it prevents dust from accumulating on them. Dust can damage tires over time, so it’s essential to keep them clean.

- Tires can be kept vertically on shelves to lessen stress and damage. This is due to the possibility of tire deformation caused by weight when tires are stacked horizontally. This can be avoided by storing them vertically.

- Avoid laying a tire directly on the ground if you must lay it horizontally for whatever reason. Instead, support should be provided by a wooden board or other similar object. This lessens the chance of the tire being harmed.

- It is essential to protect tires from direct sunshine, hot temperatures, and humidity because these conditions might harm the tire. Tires should be stored in a cool, dry area to avoid damage.

- When keeping many tires together, using one storage bag per tire is excellent because it helps prevent reactions and stains. If this isn’t possible, attempt to match the color of the bag to the tire to avoid any problems.

- It is critical to keep the tires away from the electric furnaces, motors, and pumps as these items can emit gases that can be dangerous for the warehouse facility. Therefore, it is recommended to store the tire location separately.

- It is critical to select a tire rack that is sturdy and custom-made as per the required conditions. It might cause extra costs as well. But safety comes first, so the heavy-duty tires that are being used for trucks should be loaded and unloaded using proper equipment.

Tips and Tricks for Tire Storage Racks

- Warehouses, where tires are kept, are high-risk and hazardous places because they can easily be caught by a fire hazard. So you have to assign workers to watch such severe matters at the time.

- Each country has its own fire safety rules that must be followed when constructing a warehouse plan. As a result, follow your country’s safety norms and regulations to avoid mishandling later when you may be unable to play with your goodwill.

- The NFPA-13 Standard specifies the sorts of sensors and sprinklers that need to be used in tire warehouses in order to meet safety standards. Follow your country’s rules or establish some international ones.

- It is critical to incorporate fire-fighting systems into your warehouse design to avoid dangers.

- Consider using software such as Easy WMS to run a warehouse efficiently. This software can assist in the management of all warehouse operations, particularly those linked to stock management, such as location selection, stock replenishment, and order consolidation.

- Also, using automated systems like stacker cranes can ensure quick and safe handling of goods. Especially when you need to handle large containers.

- The warehouse temperature should be maintained between 15 and 25 ℃.

- Make sure to avoid contacting the racking system filled with tires with substances like fuel, lubricants, chemicals, and so on.

- Avoid keeping the racking system near the window or door where the sunlight can directly expose the tires.

- Make sure to provide proper ventilation to the tires and do not overstock them.

Conclusion

The tire racking system is a perfect solution for tire storage effectively and securely. The industry is rapidly increasing which proves the racking system for tires will also have a boom alongside it. You can choose from different types of tire storage racks that best describe your requirements and fulfill your needs.

Also, there are tips and tricks that you can follow to have a better tire-racking solution for your warehouse. Maintenance of these racks may be required over time due to weather conditions or the events that take place unwillingly. For more racking solutions you can send a query or request a quotation from the best manufacturers in racking solutions. Feel free to contact the service team!