Are you experiencing issues with broken pallets? You’re not the only one. Therefore, many warehouse managers face problems with poor storage and high rack shelving. Well! The good news is, knowing the regulations of pallet racking systems can help you save time, space, and money.

In addition, sticking to rules guarantees the safety of your employees and your stock. In this guide, you will learn all the information necessary to choose, design, and maintain pallet racks well.

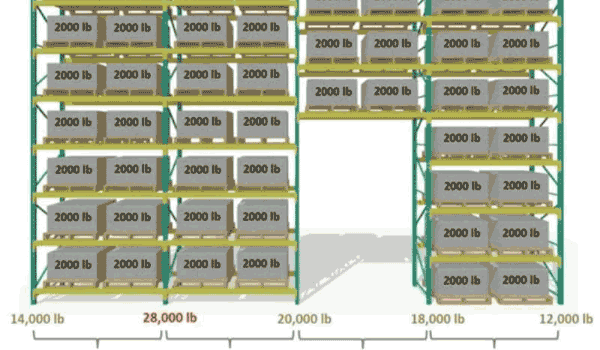

Figure 1: Pallet Racking Standards

1) Overview of Global Standard

When you use pallet racks in your warehouse, safety should come first. Therefore, standards as well as safety rules specify how to construct, maintain, and use racks, confirming their safety. So, this helps you to prevent injuries and safeguards both your employees and your equipment.

- In the United States, you comply with the standards set by ANSI/RMI 16.1 and OSHA. Moreover, they tell you what the minimum requirements for rack strength are. They provide guidance on rack installation. In addition, they specify the frequency for rack inspections.

- In Australia, you use AS4084-2023. Therefore, it guides rack design and weight points. Moreover, it also requires racks to be checked on a regular basis.

- In the UK and Europe, you obey EN 15635. This standard is useful for the safe usage of racks and their maintenance.

- In China, you follow GB/T 18218. It defines guidelines on design, load capacity, and safety concerns. Also, it explains proper installation and inspection procedures for racks.

Figure 2: Overview Of Global Standards

In addition to everything else, all standards provide regulations on sizes, spacing, and limits on loads. For instance, you know about the maximum rack height. Therefore, you know the minimum spacing required between beams.

Also, you know the procedures to arrange your loads as well. Hence, compliance with these standards ensures that your warehouse is orderly. Moreover, your safety is maintained.

2) Pallet Racking Dimensions and Design Factors

As you have learned what pallet racking system standards are. Now, in this section, we will discuss the important sizes, designs, and specifications that you must follow. Moreover, these factors will also help you in maintaining safety in your warehouse.

i) Upright Frames (Depth, Height, Width)

- Depth: First of all, the vertical frame depth must align with your pallets. Take the standard GMA pallets, which measure 48” by 40,” for example. Hence, a frame depth of 42″ is quite usable.

With this depth, the pallets will have an overhang of 3″ on each side. Therefore, this also ensures the pallets are stable and accessible.

- Height: Next, upright frames come in 2-foot increments. Therefore, their range is between 8 and 24 feet tall. Now, choose a height according to your ceiling and the height you want to stack pallets to.

For example, a 12-foot frame is good for stacking pallets up to 10 feet high. Hence, it provides good support for safety.

Figure 3: Pallet Racking Dimension And Design Factor

- Width: Then, most frames have a 3 or 4-inch width. Moreover, selecting 4” gives you additional strength to carry heavier loads.

ii) Beams and Load Capacity

- Beam Length: First of all, your beam length should match the width of the pallet you are using. For instance, a pallet that is 48” requires a beam that is 48” or a little longer. This way, you are ensuring a safe fit for the load.

- Load Capacity: Then, every beam comes with a maximum weight limit. Take, for example, a beam that is 96 long and 4 wide; it can hold 2,500 lbs per level. But for accuracy, make sure to confirm with the manufacturer’s guide, as it can be different.

Figure 4: Beam And Load Capacity

- Beam Spacing: After that, it is important to maintain the distance between beams vertically. Generally, spacing beams 4 – 6 inches apart is a good practice. So, this helps proper clearance for your pallets to be placed and removed without any risk.

iii) Clearance, Spacing, and Safety Margins

- Vertical Clearance: Now, you should maintain a minimum of 4” of space above your pallet. This avoids any potential damage and ensures safe stacking.

- Horizontal Spacing: Therefore, ensure there is a 3” gap between the back of the pallet and the upright frame. This also keeps the forklifts working safely and minimizes damage to the rack.

Figure 5: Clearance, Spacing, and Safety Margins

- Safety Margins: As with everything, you should follow the manufacturer’s instructions on weight and spacing. Otherwise, incorrect spacing or overloading may result in accidents.

3) Types of Pallet Racking System

As you understand the key sizes and design factors, you also need to learn the different types of pallet racking. Therefore, each type is beneficial for particular storage requirements. Additionally, your choice of type greatly helps you optimize space while maintaining safety.

a) Selective Racking System

First of all, selective racking is the most popular type. It enables the direct return of any pallet. As well, it is simple to install and adjust. However, it is less efficient than other types in terms of waste floor space. Therefore, you can use it when you require simple access to different goods.

Figure 6: Types Of Pallet Racking Standards

b) Drive-In / Drive-Through Racking

Next, with drive-in racking systems, you drive your forklift into the rack for the picking or placing of pallets. Therefore, drive-through is the same as drive-in. But the difference is that it is open on both sides. Furthermore, this design helps in the storage of pallets within a smaller footprint.

Hence, you can use this design in situations where you have many pallets of each stock keeping unit (SKU).

c) Push-Back Racking

Then, in push-back racking, a pallet is loaded on a rail, and it pushes the previous pallet back. So, this saves space while still giving access to the first pallet. Hence, you should choose it when you want heavy storage.

d) Narrow Aisle Pallet Racking

After that, narrow aisle racking helps you to reduce the width of the aisles to increase the number of pallets stacked. Therefore, this expands your storage capacity. Moreover, specialized forklifts are needed to access the pallets.

So, select this option if there is a space constraint and your priority is maximizing storage.

According to Alex on Quora, the first thing to think about while selecting a pallet racking system is whether you want LIFO or FIFO. After that, weigh the size and volume of your items. Then, think about your budget alongside your available space.

For instance, cold storage warehouses utilize LIFO. Additionally, they hold standard US pallets (40×48 inches and around 60 inches tall). Furthermore, he says that to increase ROI over long leases, usually lasting 8 to 10 years. So, they invest in space-saving racks.

Moreover, you need to forecast your storage needs. In addition, your selection might be influenced by the kind of equipment you use. Furthermore, every sector has its peculiar regulations. Therefore, you might require additional questions to help you decide.

Figure 7: Quora Review

4) Inspection, Maintenance, and Compliance

As you understand the different types of Pallet Racking Systems. Now, in this part, we will discuss when you need to take special care of your pallet racks.

- Regular Inspections and Audits

First of all, you should review your racks regularly. Therefore, weekly or daily visual inspections can identify glaring issues like damage or parts being out of alignment. In addition, formal audits should be scheduled at least once a year. Moreover, a qualified inspector examines structural issues, installation, and load limit compliance during the audits. So, regular inspections help to identify and fix potential problems early.

- Common Damages to Look For

After checking the racks, keep an eye out for any beams that may be cracked or bent. Also, check for any loose bolts, absent clips, or safety pins that may be damaged. In addition, check for rust and chipped paint that indicate the presence of an overloaded pallet.

Furthermore, small damages can weaken the overall structural goodness of the rack and raise safety concerns. Thus, accidents can be prevented by proactively managing issues as early as possible.

- Repair and Replacement Guidelines

Then, if you find any issues, take action right away. Some examples include replacing missing safety pins, bent beams, or cracked uprights. Therefore, always follow the manufacturer’s specified steps for replacement and repairs.

Furthermore, damaged racks should not be overlooked, because they will collapse under load. Thus, you maintain the safety, compliance, and efficiency of your warehouse operations.

5) Best Practices for Pallet Racking Safety

As you understood the concepts of inspections and maintenance, you now need to learn about safety best practices. Therefore, these measures help to avoid accidents and maintain the efficiency of the warehouse operations.

- Staff Training: First of all, proper rack use should be part of your staff training. Also, safe loading and unloading of pallets should be covered. Therefore, training your staff decreases accidents and improves overall productivity.

- Load Labeling and Documentation: Next, each pallet must be labeled with its contents and weight. Additionally, maintain storage locations for the products. Hence, this helps in avoiding rack overloads as well as in picking and tracking.

- Keeping Aisles Clear and Organized: Then, you must avoid placing anything in the aisles. Also, ensure there is sufficient space for movement for forklifts and personnel. So proper warehouse organization, you avoid collisions and speed up work.

- Regular Safety Signage: Therefore, you must put up clear signage indicating the load and height restrictions. Next, safety rules signage also serves as a reminder to your team. So, all this helps reduce errors and accidents.

Figure 8: Best Practice For Pallet Racking Standards

- Use of Personal Protective Equipment (PPE): After that, each member of your staff must wear Personal Protective Equipment (PPE) such as safety shoes, helmets, and gloves.

Furthermore, ensure that everyone observes safety protocols for working with racks. Hence, you ensure safety for yourself and for others when you use Personal Protective Equipment (PPE).

Conclusion

In short, following pallet racking standards provides safety within your warehouse. In addition, proper design and types of racks enhance productivity. Therefore, you need to perform regular inspections and maintenance on racks. Also, set load limits and train your personnel accordingly.

Furthermore, by taking these measures, you save injuries and accidents. So you may visit China Storage Rack for the Pallet Racking system. Moreover, this helps you to optimize the design of your warehouse.