In warehouse management, we generally believe that the main work includes: goods acceptance into the warehouse, storage, circulation processing, preparation picking, out of the warehouse delivery, etc., and arranging the location of these processes, determining the movement of goods in the warehouse route. This is called the warehouse goods flow line.

The design of the warehouse movement line is the basis of the operation of the entire warehouse logistics center, reasonable movement line design in order to make the warehouse system operate more effectively.

Dynamic line design analysis

We mainly analyze two objects, one is the execution of the action, one is the path of travel. However, before analyzing these two objects, we must first distinguish the goods, the goods are different, the meaning of the action and path is not quite the same, we make a distinction, mainly to determine several issues:

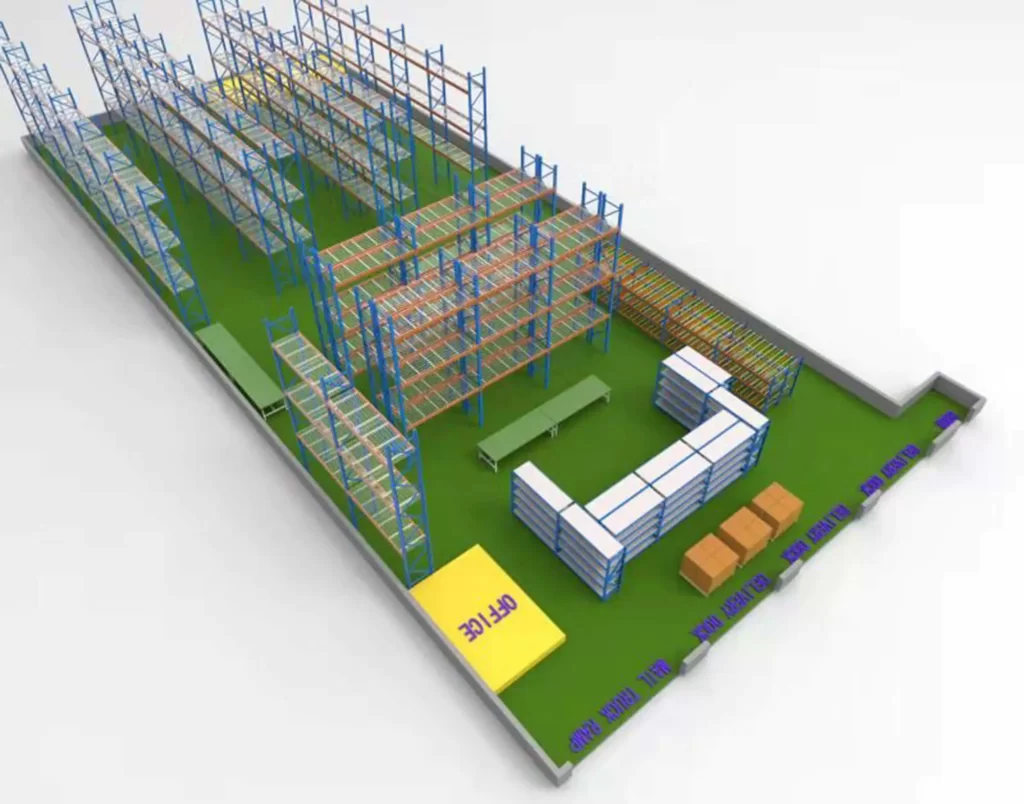

1. The first is the proximity of the entrance and exit. Normally, the warehouse site route arrangement, will only leave an entrance, an exit, the goods from the entrance into the warehouse, the exit out, if the entrance and exit are in the same direction, the goods in the warehouse arrangement, there are close to or away from the entrance and exit arrangement problems. Some warehouses due to the conditions, the entrance and exit are the same, then near or far from the impact is even greater. Of course, there may be a situation, is a large number of goods, in order not to affect the operation of other goods, specifically set up a separate entrance and exit.

2. The second is the distance from the main aisle of proximity. Out of saving area considerations, the warehouse site aisle has the main and secondary, the main aisle is more spacious, normal will ensure that the warehouse delivery vehicles or other tools in both directions through, secondary aisle treatment will be worse, generally only to ensure that one-way through, or even according to the reality of the situation, only allow smaller delivery tools one-way through.

For example, the main aisle and the secondary aisle of the pallet storage area are designed according to the width of the pallet, but the light racking area only allows small picking trucks to pass in one direction, and even only allows picking personnel to pass in front of or to the side. Obviously, near or far from the main aisle on the operation of the impact is still relatively large, whether it is into or out of storage, near the main aisle to save some time and effort.

3. The third is the storage and delivery vehicle in the storage area. The simplest, is it stored on pallets or racks, or other storage containers? What tools will be used for transferring, or picking, in the storage area?

4. The fourth is the height position on the rack. This is related to the height of the picker. How high is the operator’s eye level when picking? How high is the operator’s operating comfort zone? For goods that need to verify information or identify inventory, they are generally placed below the eye level, while the most frequently operated goods are concentrated at the operating comfort height as much as possible. These are easy to understand.

Cargo analysis

1. According to lightness and weight

In general, the heavier the goods of course closer to the entrance and exit, closer to the main aisle, placed on the racks of the lower area as good; and lighter goods can be farther away and higher. However, the warehouse is prone to encounter a situation where there are many heavy goods, and few light goods, the lower level of space is not enough, while the higher racks are very empty, this time, it depends on the turnover rate or operating frequency to decide.

2. According to the size

This is an interesting question – we generally feel that the bigger things are not suitable to be placed higher, in fact, make such a judgment because we have an intuition that the bigger things are heavier. In practical terms, many times, the same weight, the larger things are more suitable for high places, there are two main factors.

The first is that the lower-level space is more valuable than the upper-level space, the more space-consuming things, are put up high to make more room for other things.

The second is that the larger things are more convenient to operate, picking goods at a glance, no need to check information, it is also easy to identify the inventory, take out is also easier than taking small items some.

3. According to the amount of inventory

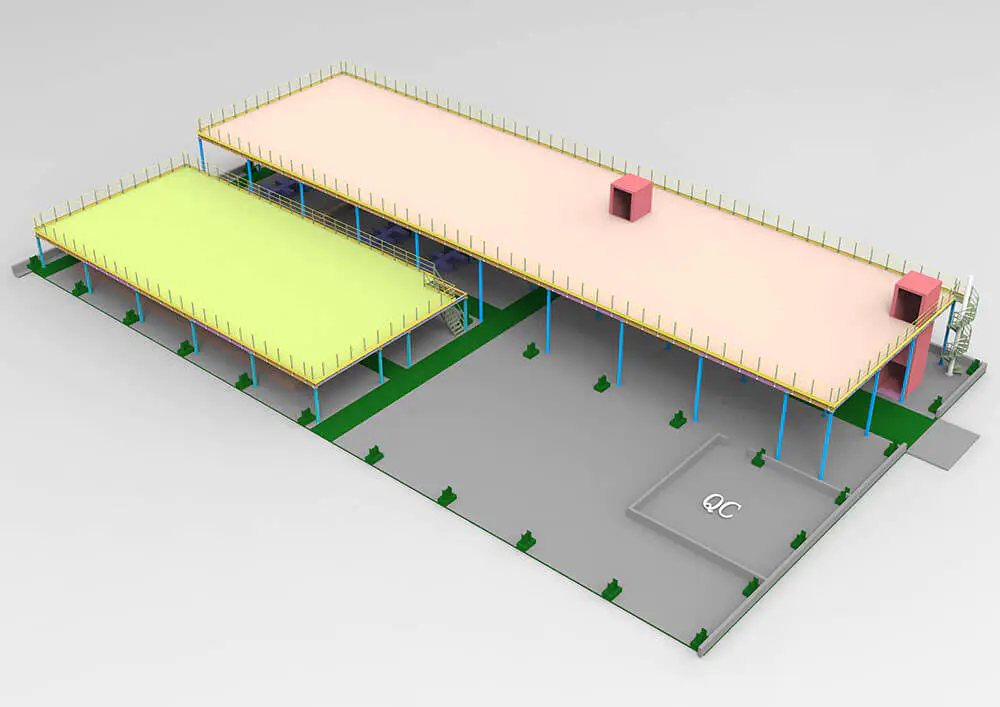

Generally speaking, small quantities of goods are placed in small storage spaces such as racks, while larger quantities of goods are stored mainly on pallets, and as for very large quantities of goods, specific storage areas can be planned, and no aisles are left between the same batch of goods of the same kind, thus maximizing the use of warehouse area.

4. According to the turnover speed

The faster the turnover of goods, naturally close to the entrance and exit and the main aisle is better, the height on the racks should also be adjusted to a more comfortable area.

5. According to the value of goods

We are mainly concerned about the storage of valuables. If there are conditions, a special area for valuables can be set up in the storage area and locked separately, with special operators designated; for small batches, special material cabinets can also be used to store valuables and other goods that require special operation in a locked cabinet. In addition, various registration measures and monitoring equipment are also focused on care.

6. According to the whole dispersion

In pre-planning, it is easier to overlook the difference between whole and part. We will mainly discuss two aspects.

One is the bulk entry and single piece of goods out of the warehouse. For large quantities of goods, of course, we focus on close to the entrance and exit, so the question arises, in the end is close to the inlet, or close to the exit?

Our conclusion is that for the batch into, batch out of the goods, near the inlet or outlet does not make a difference, because in the warehouse inside the operation and walking path is the same, most of the pallets as a unit of operation. For the batch into, single piece out of the goods, it is appropriate to close to the exit, because this can maximize the savings in picking out of the path of handling.

For example, if there are a total of 10 pieces of goods, and only one trip is needed for inbound storage, but 10 trips may be needed for outbound picking, we should of course try to shorten the walking distance for picking, that is, to keep the goods close to the outlet.

One kind of goods is the whole piece into the warehouse, splitting zero out of the warehouse. In actual operation, the box is often kept in a closed state, then each picker needs to open the box first, and then take out the goods, which is two actions, inconvenient for one-handed operation, and inconvenient for counting the quantity, which has a relatively large impact on the operation efficiency.

It is difficult to have an absolute judgment as the design of movement line needs to consider various factors.

In fact, this is a resource allocation problem, in the warehouse, different storage locations suitable for different goods, will be different kinds of storage space priority allocation to which goods, requires careful consideration.

Fully considering the several characteristics of the goods and the real conditions of the warehouse, we have a general concept of the specific storage location of different goods.

In practice, we generally according to some of the characteristics of the goods for classification, but also to the library of the storage space for classification, in accordance with a more scientific and accurate classification of effective storage management, is the necessary homework of the warehouse management team.