WhatApp: +86 13713386306

Email: nancy@chinastoragerack.com

Phone: +86 18578478231

WeChat: +86 18578478231

Pallet rack dividers are used to divide pallet racking into smaller storage units and are often designed to match a pallet rack. They are a great way to organize and separate goods and can help prevent items from getting mixed up for easy access and retrieval. Dividers can be used in any type of pallet racking system and come in a variety of sizes and materials. They can be used to divide pallet racks by product, size, or even color. They are also great for organizing inventory to ensure that the right items are always in the right place while protecting them from damage.

When choosing pallet rack dividers, there are several types to choose from. Each type has its unique advantages and disadvantages, so it’s important to understand the differences between them to determine which type is best for your needs.

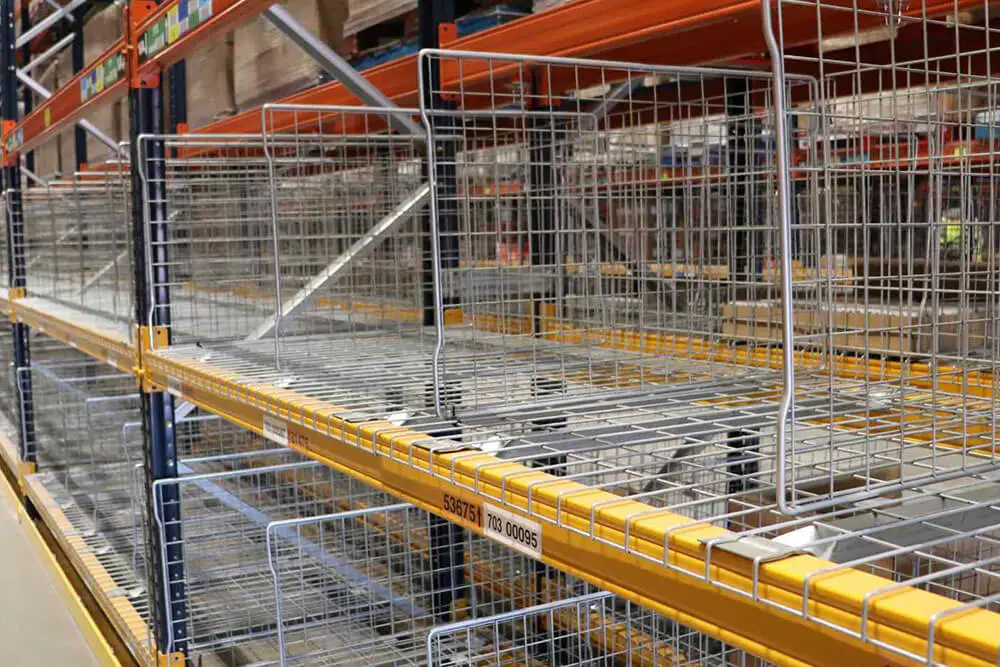

Wire mesh pallet rack dividers are lightweight and easy to install. They allow visibility and air circulation, which can help reduce fire risk and improve ventilation. They are also economical and easy to replace if they become damaged. However, wire mesh dividers do not offer as much protection as solid dividers and may not be suitable for storing smaller items.

The pallet rack M divider is named after its shape, which resembles the letter “M”. It is usually fixed to the pallet rack beam at regular intervals Pallet Rack M dividers are durable and long-lasting. They can withstand heavy loads and resist bending and warping. They are also fire resistant and can provide additional support for your pallet racking.

Which type of pallet rack divider is best for your needs? This ultimately depends on your specific storage requirements. Consider your specific needs and talk to a professional to determine which type of divider is best for your application. By choosing the right material for your pallet rack dividers, you can improve the efficiency and safety of your warehouse operations.

Pallet rack dividers are an important part of any warehouse that uses pallet racking. There are many benefits to these dividers, and here are five reasons why pallet racking dividers are vital to your warehouse.

Pallet rack dividers can help organize your warehouse by creating separate storage compartments for different products. This can make it easier to find and access the products you need and can help reduce the risk of misplacing or losing items.

Pallet racking dividers can help improve warehouse security by preventing products from falling or shifting. This reduces the risk of accidents and injuries caused by falling objects and can help protect your employees and products.

By using pallet rack dividers, you can reduce the risk of product damage, which can help you save money in the long run. By preventing products from falling or shifting, you can avoid costly repairs or replacements and reduce the risk of product damage during storage.

Pallet rack dividers can help you manage your inventory more effectively by providing a clear visual separation between different products. This can make it easier for you to track inventory levels and replenish products as needed.

Pallet rack dividers can help you make the most of your warehouse space, allowing you to store more products in a smaller area. By creating separate compartments for each product, you can use your available space more efficiently and reduce wasted space.

Proper installation of pallet racking dividers in the warehouse is critical to ensure product organization, convenience and safety. Here are the steps to follow to properly install pallet rack dividers in your warehouse.

1. Determine the type and size of divider you need.

Before installing pallet rack dividers, you should determine the type and size of dividers you will need based on the products you plan to store. Consider the weight and size of your products, as well as any special requirements for storing them.

2. Prepare your racking system.

Before installing dividers, make sure your shelving system is clean and free of any debris. If necessary, repair any damage to the shelves or add additional supports to ensure your dividers will be stable.

3. Position your dividers.

Place the dividers in the ideal position for your shelving system. Make sure the dividers are level and properly aligned with the pallet racking.

4. Secure the dividers.

Depending on the type of dividers you are using, you may need to secure them to the pallet rack with brackets or clips. Make sure your dividers are securely fastened to the shelves to prevent them from falling or shifting.

5. Test your dividers.

Once you have installed your dividers, test them to make sure they are stable and secure. Try moving them around to make sure they are securely fastened to the rack.

5. Label your dividers.

Label your dividers with the product name or SKU to help you identify the contents of each storage compartment. This will make it easier for you to find and use your products when you need them.

Your email is absolutely secure and we’ll not disclose it to any third party for any reason.

Your email is absolutely secure and we’ll not disclose it to any third party for any reason.