Industrial Mezzanine design is fast becoming the preferred solution for economical and highly efficient workspaces as people strive to maximize their warehouse cube space. It allows you take advantage of your vertical and floor spaces, and every other place. Industrial mezzanine designs satisfy your industrial need: be it single-level storage or multi-level pick models.

It is essential to define the intended purpose to help understand the design style and expected load strength since industrial mezzanine spaces are customizable and permanent structures.

Dissecting the Meaning of Industrial Mezzanine Design

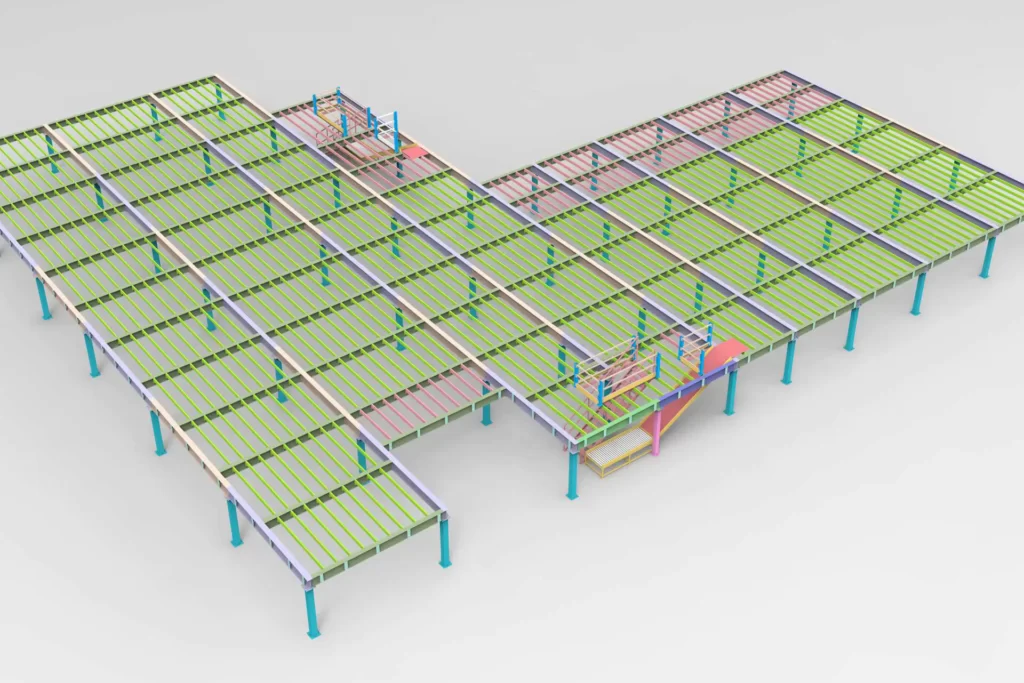

Industrial Mezzanine are elevated floor systems fitting between the ceiling and the floor of a facility. The facility could be industrial, manufacturing, commercial or distribution. Industrial mezzanine structures are often constructed from heavy steel and are helpful to maximizing your storage ability without wasting floor space.

There are different kinds and structures of Industrial mezzanine designs and each of these designs serve different purpose.

Structures of Industrial Mezzanine Design

Industrial mezzanine designs differ by function, size, and structure. Although the main intent of an industrial mezzanine is to increase the total usable space in a facility, the designs serve different purpose.

There are four common industrial mezzanine designs. They include the following:

- Rack-Supported or Shelving

- Freestanding Industrial Work Platform (IWP)

- Full Mat

- Catwalk

These designs have different industrial uses. For example, warehouses use rack-supported and freestanding IWP structures for similar purposes. The cost and construction style of these mezzanine designs are also different. This indicates that there are different factors to consider when choosing a suitable industrial mezzanine design. They include cost, design, purpose of use, structure, safety, and aesthetics.

Let’s look at these industrial mezzanine designs in relation to these factors.

Freestanding Industrial Work Platforms

Industrial work platforms are freestanding designs that are usually costly to construct initially, but you can quickly move and reconfigure them when the need arises. Industrial work platforms serve numerous purposes. You can design and build them for light-duty or heavy-duty purposes.

Basically, there are five structural framing options for freestanding IWPs. They are:

Bolted C-Section: It has a small-medium size with a load capacity of up to 200 PSF.

Beam & C-Section: It also has a small-medium size and storage capacity of up to 200 PSF.

Beam & Beam: It has a small-medium size and unlimited load capacity.

Beam & Bar Joist: It has a medium-large size and up to 300 PSF load capacity.

Truss Girder & Bar Joist: It has a large size and up to 300 PSF load strength.

You can use the IWPs to handle the workload of a demanding operation. You can design heavy-duty rails, lifts, gates, ladders, and stairs into your facility when the need arises. Different decking choices offer adequate coverage for your needs like open grating, heavy-traffic, or moisture-resistant surfacing.

Advantages of IWP Construction

Below are reasons you may consider the freestanding industrial work platform over its counterparts:

- It has fewer columns than rack-supported mezzanines.

- It is more versatile due to unique column design and placement.

- It is more versatile with modifications, drop gate, stair, and handrail placement.

- You can add sprinkler systems to the webbing in girder system and joist modules.

- It can quickly absorb operational adjustments like adding conveyor, offices, shelving, carton flow, or workstations.

Demerits of IWP Construction

Despite being the preferred choice for numerous applications, it is crucial to understand the few constraints attached to this option. The downsides include:

- You may need footings, depending on the concrete and the number of mezzanine levels.

- It is more expensive than rack-supported mezzanines.

- You need support structure for pallet flow or carton flow applications.

- It generally has lower clearance beneath the module than a rack-supported facility.

Shelving or Rack-Supported

Shelving or rack-supported industrial mezzanine design is a cheaper alternative to the IWP. Although shelving or rack-supported mezzanine designs are cheap to construct initially, they are more challenging to reconstruct because they have more columns in the design than industrial work platforms.

You can design this mezzanine over the aisle space and within the pallet racking. Alternatively, some design it above the racking uprights.

It is best to bolt the mezzanine frame to the uprights and fit the decking to it to secure the structure. You can access pallet storage beneath and on the perimeters while using the increased square-footage of the structure above. This arrangement ensures a cost-effective deployment of the pallet rack.

Similar to industrial work platforms, you can diversify the flooring options to accommodate the platform role. Also, you can attach lifts, stairs, railings, and conveyors to the facility. However, it may need more structural support beams to achieve this purpose.

Advantages of Rack-Supported Mezzanine Construction

- It is less expensive to an industrial work platform.

- It allows you to support pallet flow, pallet gates, conveyor, carton flow, stairs, and cantilever shelving.

- You do not need footings when constructing multi-layered levels.

- The racking system makes it more visually attractive.

Disadvantages of Rack-Supported Mezzanines

- It requires more columns than the IWP.

- It becomes rigid than the road.

- It is more challenging to expand along the footprint of cross-aisle direction.

Ultimately, the two options are cost-effective than constructing new structures. Also, you can reduce the downtime to construct your new platform with proper planning and excellent engineers to execute it.

Catwalks

Basically, catwalks are industrial mezzanine designs that serve as a transport system within the facility workspace. They are light-capacity passageways developed to permit employees safely move from one end to the other without disrupting operations or experiencing motor vehicle traffic. This style is a smart way of enhancing warehouse safety and use the available vertical space judiciously.

Full Mat

Primarily, a full mat design serves as an office space. It is a combination of freestanding IWP and catwalk styles.

A full mat mezzanine design can serve various purposes. It is one of the most versatile mezzanine designs. Because they have a large floor area, you can use the full mat mezzanine design as a storage area, an office space, install shelving, retail rooms, cafeteria, and even workspace.

To install a full mat mezzanine design, they are supported by shelves or racks. Thus, it is essential to note that the shelves’ height does not exceed the mezzanine floor.

An Insight into Industrial Mezzanine Design Load Capacities

You can deploy mezzanines for picking and processes, equipment, storage, production, and personnel spaces when trying to add more functional space to your manufacturing facility or warehouse. The engineering team will strategize space and corresponding load strengths for the given role and the mechanical, safety, and structural equipment needs.

The International Building Code (IBC) has given load strengths from minimum to heavy-duty deployment in pounds per square foot (PSF) shared over the platform.

- Minimum use includes limited access maintenance or conveyors and should be 60 to 90 PSF

- Storage warehouse includes light manufacturing and should be 125 PSF

- Storage warehouse includes heavy manufacturing and should be 250 PSF

An industrial mezzanine design is constructed to suit the total expected load capacity of the intended purpose. However, for future use and to ensure cost-effectiveness, it is cheaper to construct for an industrial mezzanine design with heavier capacity from the outset than adding load strength to an old structure.

There are different factors determining mezzanine capacity and they include the intended purpose, work platform height, dead load and live load weight, weight distribution across the mezzanine, warehouse floor, and columns.

Many other factors influence the load capacity of the work platform apart from the intended purpose. The other essential factors in engineering the desired load strength include the thickness of the warehouse floor, the soil quality beneath, and the method of weight distribution across the mezzanine.

There are other concepts to understand about the load capacity of an industrial mezzanine design.

Slab Capacity

Ideally, the slab thickness of an industrial structure floor should be 6”, containing 4,000 psi. While it is enough for 25,000 lbs. operations, the water table level and soil quality below the floor minimize the capacity and determine the need for footings to erect an industrial work platform.

Uniformed Load or Columns (Quantity and Spacing)

Locating the uniform load is the next line of action. For instance, according to the IBC specifications, a heavy-duty mezzanine contains 250 lbs. PSF capacity. It is crucial to always allow a licensed engineer determine the actual load capacity as the figure in this piece is only an estimate.

You can determine the number of columns required and the spacing to adequately enhance the load uniformly across the entire mezzanine and on the other given slab using the column loading.

The Place of Point Loads

Industrial mezzanine design structures have places where machinery or stacked items will affirm extra load in a particular area on the mezzanine above the shared load strength.

Concentrated load areas are point loads. Your engineers must design the facility to support and share the weight safely. It is crucial to differentiate between dead and live loads when thinking of load distribution. Live loads are mobile or movable features, while dead ones are permanent, like walls.

Uses of Industrial Mezzanine Design

As noted above, industrial mezzanine designs serve different purposes. Although the main purpose of industrial mezzanine is to increase total usable space in a facility or warehouse, its use is heavily dependent on the type of industrial facility using it.

For example, a distribution facility may construct a mezzanine structure to serve majorly as storage space, while a manufacturing facility may construct a mezzanine to place dead equipment or as an office space for managers or supervisors.

The typical uses of mezzanines include:

It Serves as Work Platform

The most typical use of a mezzanine is as a workspace. Structures with limited space can add a mezzanine to increase their square footage without needing to expand the entire facility. Mezzanine work platforms can assist employees in dealing with assignments without clogging up lower walkways by leveraging vertical space.

Some dedicate their mezzanine work platform for packaging, assembling, or order fulfilment, depending on their specific needs.

It Serves as a Catwalk Platform

Also, people often use mezzanine as a catwalk platform. There are catwalk-centered industrial mezzanines to meet this popular demand.

Catwalk mezzanines work with a straightforward reason at their core—to safely move personnel from Point One to Point Two on a lifted platform.

The benefits of this process includes freeing up floor space, developing more productive and organized employee traffic lanes, and promoting the overall efficiency and safety of the facility. Platforms with high foot traffic must meet specific safety standards before setting up.

It Serves as a Conveyor Support Platform

Conveyors are a typical equipment for distribution centers and warehouses. Apart from streamlining numerous facility operations, they also contain a commendable bit of floor space.

The demand for efficient configurations that reduce the influence on square footage is necessary through the automation of more warehouse processes. The solid steel development of a mezzanine can enhance automation processes overhead. Employees can smoothly and liberally work on the ground level by placing conveyor tool on the mezzanine platform.

It Serves as Shelving or Rack Implementation

Developing efficient storage methods is essential to organizing your facility. It mostly means using items commercial or industrial shelving and pallet racking. You can quickly maximize your storage potential and gain much space by implementing a mezzanine design for your shelving or racking.

The options available to you when using a mezzanine with shelving or racking include shelving-supported, rack-supported, and shelving on catwalk. The shelves or racks support the mezzanine deck for the first two options. It adds cherished floor space above an old storage item. The shelving expands vertically via the mezzanine deck for the shelving on catwalk-style mezzanines.

It Serves as Storage Space

The most typical use of a mezzanine is storage space. It is quick and painless to use the facility as an additional storage space. You can use the facility as a tentative storage space if you decide not to opt for a shelving solution. It offers you different choices on suitable use of your structure.

The need for flexible storage space takes the center point as organizations grow and expand. The mezzanine platform provides valued accommodation for crucial documents, records, and tools; it is a peaceful habitat to virtually everything! Also, you can quickly access your stored materials due to gate installation and other mezzanine tools.

It Serves as an Observation Platform

It is usually challenging to get a bird’s eye view of operations in a big warehouse setting. Commendable sightlines are usually absent despite all the storage tools like shelving shooting upward and pallet racking.

You can build a superb observation platform by including mezzanine to your facility. You can quickly watch operations from there. The merits of this act include assessing facility performance, evaluating unproductivity in present operational workflows, and keeping a keen eye on safety protocol compliance.

It Serves as In-Plant Office Space

You can also use a mezzanine as an in-plant office facility. You can use the height of the mezzanine facility to develop office space without forgoing the square footage below. It saves you from the hassles of constructing an office space on the ground floor. It makes your space smarter and more charming.

It is a smart way of consolidating the otherwise far aspects of your workforce. Leaders can still tap in the merits of enclosed workspace for routine operations without being too distant from the real action.

Furthermore, you can configure mezzanine office space. It means you can include soundproof paneling, custom window placement for smooth workflow viewing, and insulation for power efficiency. Adding these features will help your structure stand out. It helps you to customize it to your taste.

It Ensures Access to Equipment

Equipment maintenance is a warehouse operation aspect causing havoc for personnel. It is usually the case when equipment is bulky. It makes it hard for ground-level access for maintenance or repairs.

However, mezzanine makes equipment and machinery quickly accessible via the platform. Furthermore, you can configure industrial mezzanine design to enhance quick maintenance for the workforce. It is usually safer and more efficient to use a mezzanine than a mobile or fixed ladder.

Conclusion: The Future Is Ultimately All about Industrial Mezzanine Designs

Thinking ahead is one of the most crucial cost-effective approaches to industrial mezzanine design. It is logical to anticipate increased mezzanine load strength in the initial building than to “include” additional load capacity to the existing facility or tackle the construction challenges during the process.

Being reactionary will not give you the intended results. When the foundation is fragile, your engineering team can barely do anything. Resolving unanticipated complications will be costly and time-wasting. Hence, it is essential to count the cost from the beginning.

One of the ways to stay ahead is engaging a firm that is experienced in every realm of industrial mezzanine design, project management, installation, and engineering. The firm will work within your schedule and budget, whether you are constructing a new or adding to your existing structure. You can also check out their mezzanine gallery for inspirations on modern and exquisite design. If you creatively put yourself ahead, it becomes challenging for anyone to dislodge you.