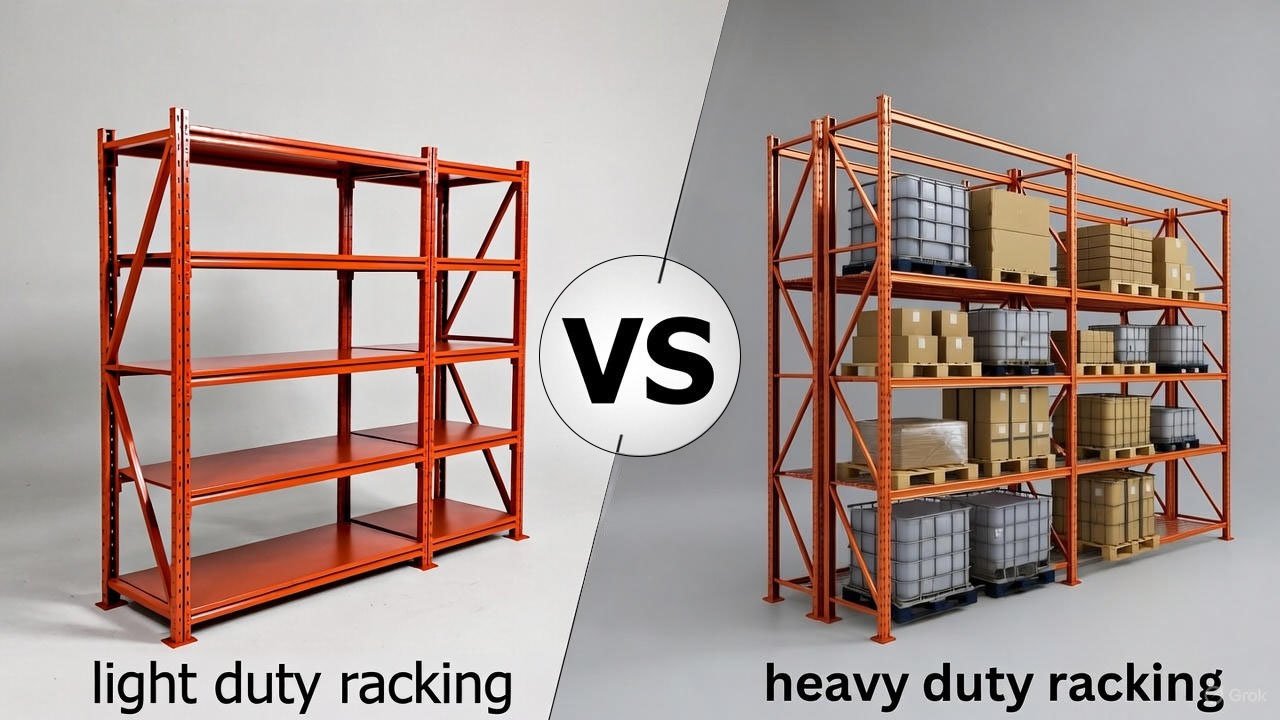

Are you trying to choose the perfect racking system for your storage needs? Okay! But picking the right type can be difficult for you. Heavy-duty and light-duty racks fit different purposes.

Don’t worry! In this guide, you will learn about the differences between heavy-duty and light-duty racking. Also, you will learn their load capacity and ideal applications. By the end, you’ll know which racking system suits your warehouse, office, or retail storage needs.

1) Definition and Overview

You need the right rack when you store items. As you know not every rack can hold the same amount of weight. Well, your choice depends on what you’re storing and how much it weighs.

First of all, a heavy-duty racking system is very strong. You can use it for pallet racks, machinery, or large amounts of material. Also, you’ll usually see it in large warehouses or distribution centers. Because it can handle heavy loads and durable under pressure.

Figure 2: Heavy-Duty Racking

On the other hand, light-duty racking is different. You can use it for lighter items like office supplies, small inventory, or retail stock. So, it fits well in small spaces and can be easily installed. Also, you can move and adjust it according to your needs.

Figure 3: Light-Duty Racking

To be straightforward, if you want strength and durability. Then you choose heavy-duty. But if you want flexibility and easy installation. Then light-duty is the best choice for you. This choice will keep your storage safe and organized.

2) Load Capacity

You need to examine how much weight it can hold when you store items. This is called the load capacity. Well, when you choose the right capacity. Then it keeps your items safe and protected from damage.

Well, Heavy-duty racking systems can carry very heavy loads. You can store pallets and machinery on it. Most shelves can hold 1,000 to 5,000 kilograms or more. So, it is ideal for your factories, warehouses, and large storage areas.

Figure 4: Heavy-Duty Racking Load Capacity

On the other hand, light-duty racking is for your lighter items. It usually holds up to 500 kilograms per shelf. So you can safely store boxes, office supplies, and small inventory on it. Well, it is ideal for your retail stores, small warehouses, or offices.

| Feature | Heavy-Duty Racking | Light-Duty Racking |

| Load Capacity | 1,000–5,000 kg+ per shelf | 500 kg per shelf |

| Ideal For | Pallets, machinery, bulk storage | Office supplies, retail stock, small inventory |

3) Material and Construction

After that, the material and construction of a rack affect the strength and lifespan of your rack. So you choose based on how much weight you will be storing and how you will use it.

Heavy-duty pallet racking is built to last. Usually , it is made of thick steel, strong beams, and welded joints. This allows it to handle heavy machinery or pallets without bending. Also, it is suitable for your daily use in large warehouses or factories.

On the other hand, light-duty racking is lightweight and can be moved easily. Usually, it is made of thin steel, bolted frames, or a combination of wood and metal. Well, this makes it easy to assemble and adjust. Also, it is ideal if you move the rack frequently or store small items.

Figure 5: Light-Duty Racking Material and Construction

4) Design and Configuration

Also, the design of your rack affects the effective use of your storage space. So you choose a system that suits your storage needs and warehouse layout.

Heavy-duty racking comes in strong and well-organized designs. Common types of heavy duty rackings are:

- Pallet racking

- Cantilever racking

- Drive-in or drive-through racking

Well, this setup helps you to store heavy and bulky items securely. And you use forklifts or machinery to move them easily. So it is ideal for maximizing storage in your large warehouses.

Figure 6: Heavy-Duty Racking Design and Configuration

On the other hand, light-duty racking is simpler and more flexible. Common light duty rocks are:

- Shelving units

- Boltless racks

- Adjustable shelving

Well, you can easily move them or rearrange them to fit your storage needs in your small space.

To be honest, both types help you make efficient use of space but in different ways. Heavy-duty racking maximises vertical storage and handles your heavier loads. On the other hand, light-duty racking helps you for efficient storage in small spaces and can be adjusted to changing needs.

5) Applications and Use Cases

Well, it is important to know where and how it will be used when you choose a racking system. Because different racks are suitable for different environments and storage needs.

i) Heavy-duty racking:

- First of all, it is used to store large machinery and materials in manufacturing plants.

- Next, you use heavy-duty warehouse racks for bulk storage.

- Well, it is ideal for automotive parts as it can safely handle heavy weights.

Figure 7: Use of Heavy-Duty Racking

ii) Light-duty racking:

- First of all, it is ideal for storing files and supplies in offices.

- Next, retail stores use it to organize products and stock.

- Well, it is also suitable for light inventory in small warehouses.

- After that, you can also use it for personal or home storage to keep items neat and easily accessible.

Figure 8: Use of Light-Duty Racking

6) Cost Considerations

Afterward price is a big factor when you choose racking. So you need to consider the initial investment and long-term maintenance.

Figure 9: Cost Considerations

Heavy-duty racking is usually more costly in starting. Well, the stronger materials and construction make it expensive. But it lasts a long time. With time, it can save you money because it requires less replacement and it handles heavy loads safely.

On the other hand, light-duty racking is cheaper to buy. Also, it is easier to install and requires less starting cost. However, it does not last as long in heavy use. Well, you should weigh the price against your storage needs and frequency of use.

7) Advantages and Disadvantages

Moreover, it is very important to understand the advantages and disadvantages of every type when you are choosing a racking system. Well, this will help you choose a system that suits your operations.

Advantages of Heavy-Duty Racking

+ First of all, it can safely store heavy items such as pallets, machinery, and bulk materials.

+ Next, it has a long lifespan and can withstand daily industrial use without bending or breaking.

+ Also, it makes maximum use of vertical space. So it is ideal for large warehouses and factories.

Disadvantages of Heavy-Duty Racking

– However, it is expensive and requires professional installation.

– Well, maintenance and safety inspections are more labour-intensive and time-consuming.

– At last, it is less flexible and difficult to move once installed.

Advantages of Light-Duty Racking

+ First of all, it is inexpensive and easy to install. Also, it saves you time and money.

+ Next, you can adjust or move it as needed, which delivers flexibility.

+ At last, maintenance is easy, and safety inspections have to be done less frequently. So it makes your management easier.

Disadvantages of Light-Duty Racking

– On the other hand, it cannot handle very heavy items.

– Also, it has a shorter lifespan than heavy-duty racking.

– At last, it is not suitable for environments with heavy and continuous use.

Decision-making criteria

- First of all, you look at what items you want to store and how much they weigh.

- Next, you think about your available space and see how you want to use it.

- Also, you consider your budget for the initial investment and long-term maintenance.

- At last, you decide how often you will need to move or adjust the racks.

Well, by carefully considering these pros and cons, you can choose a racking system that is safe and best suited to your storage needs.

8) Comparing Heavy-Duty and Light-Duty Racking

To choose the right racking, you should compare the key features of both types. Here, we will understand it:

| Feature | Heavy-Duty | Light-Duty |

| Load Capacity | Very high | Low to medium |

| Material | Steel, reinforced | Steel, aluminum |

| Installation | Professional setup | Easy DIY |

| Cost | Higher investment | Lower cost |

| Durability | Long-term | Moderate |

| Ideal For | Factories, warehouses | Offices, retail |

9) Installation and Maintenance

Before using any racking system, it is important to understand how to install and maintain it. Well, your proper installation and regular maintenance guarantee the safe use of your storage space.

Figure 10: Installation and Maintenance

Heavy-Duty Racking: Installation and Maintenance

i) Professional Installation Required: First of all, heavy-duty racking usually requires professional installation. Its structure is strong but complex, consisting of thick steel and reinforced beams. So your proper installation ensures stability and safety.

ii) Complex assembly: Next, the assembly affects welded joints and many components. You cannot assemble it yourself without guidance. Well, every part must be properly aligned to support your heavyweight.

iii) Regular safety inspections: Well, after installation, you inspect the racking regularly. So you look for loose bolts, bent beams, or any other defects. So this inspection prevents accidents and makes your system reliable.

iv) Maintenance requirements: Also, more maintenance is required than for light-duty racks. Well, cleaning and tightening of parts are necessary to maintain strength.

v) Long lifespan: At last, the advantage is that heavy-duty racks last a long time. They can withstand heavy daily use without bending or breaking. So it makes them ideal for warehouses and industrial storage.

Light-Duty Racking: Installation and Maintenance

i) Easy Installation: First of all, Light-duty racking is very easy for you to install. Well, you can set it up yourself or with a little help. So this saves you time and effort compared to heavy-duty systems.

ii) Simple Assembly: Because it uses thin materials and bolted frames, assembly is easy. You don’t need special tools. And you can also change or move it as needed.

iii) Low-cost Maintenance: Also, maintenance is easy and low-cost for you. So, only a few cleaning and minor checks are enough.

iv) Fewer safety inspections: Moreover, safety inspections also have to be done less frequently. So it makes management easier and less time-consuming for you.

v) Lifespan Consideration: However, you should be aware that its lifespan is shorter than that of heavy-duty racking. Well, it works best for storing light items and low usage.

vi) Flexible and Adjustable: At last, you can easily rearrange it according to your space and storage needs.

Final Thoughts

In short, when you are choosing a racking system. Then, you think about your space and needs. Heavy-duty racks are best for your industrial storage. On the other hand, light-duty racks are suitable for your offices and small warehouses. Also, you consider weight, budget, and flexibility.

Furthermore, we, at China Storage Rack, offer you durable and easy-to-install racking solutions. Also, our racks are suitable for your warehouses, offices, and retail spaces. Contact us today for orders and more information.