Picking the right racking system is important if you manage a warehouse. It impacts your storage and working security. Well, single-deep and double-deep racking are two famous options. You may be thinking, which one is best for your warehouse?

This guide will help you understand the features of double and single deep racking. Also, we will discuss the benefits and limitations. So you can choose the best system for your stock.

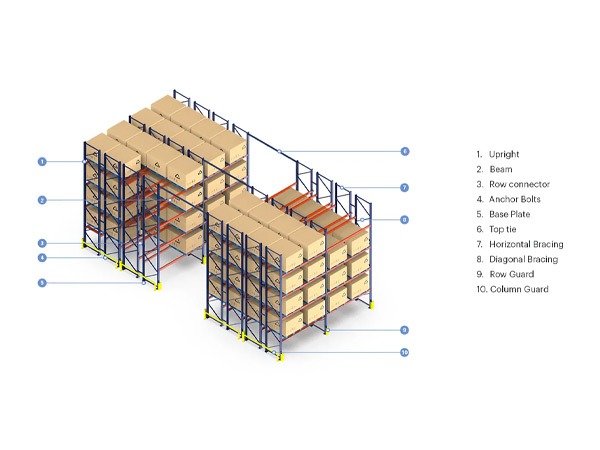

Figure 1: Double Deep Racking vs Single Deep Racking

1) What Is Single Deep Pallet Racking?

First of all, single-deep pallet racking is the common storage system used in warehouses. You only store one pallet deep on every side of every aisle. Well, each pallet is facing the aisle. This means that you can reach any pallet immediately. Also, you don’t need to remove any other pallet.

Well, single-deep pallet racking is also known as a standard selective racking system. This system is simple and reliable for you. You can control per pallet individually. So this feature speeds up your daily work. Well, that’s why this system is popular in new and old warehouses.

Furthermore, this system is used in almost every type of warehouse. You can install it in distribution centers. Also, it is suitable for your retail storage. Well, this system is perfect if you have a different type of item. It is particularly beneficial for fast-moving goods.

Figure 2: Single Deep Racking

- Key practical features

After that, in this system, you get 100% pallet access. You can control the inventory easily. Well, stock counting also becomes easy. You can use a regular forklift. So no special machine or additional training is required. To be honest, installation is also easy. Maintenance is low-cost and simple. That is why this system becomes a safe and practical choice for you.

2) What Is Double Deep Racking?

On the other hand, double-deep racking is a storage system in which you store two pallets deep on either side of an aisle. Well, this system helps you to store more pallets in the same space. Also, you store two pallets in every rack, one at the front and one at the back. In this way, you can enhance your storage capability.

Figure 3: Double Deep Racking

- How does a double-deep rack system work?

To be clear, a double-deep warehouse racking system is similar to single-deep racking. But it has an extra pallet placed at the back. So you can reach the pallet in front directly. To be honest, the pallet in the back only comes out when the one in front is removed. This is why order becomes important in pallet handling.

Well, this system works on partial access. You do not have immediate access to all the pallets. Usually, this system works on the LIFO principle. That is, the pallet that is placed last is the one that is removed first. Obviously, this system is better for items that have the same movement. So, if you have a large amount of the same type of stock. Then this system is good for you.

3) Double Deep Racking Dimensions and Layout Design

After that, double-deep racking systems are designed to store more pallets. Well, it is very important to know its exact dimensions. Incorrect measurements can affect the efficiency of your warehouse.

Figure 4: Double Deep Racking Dimensions and Layout Design

i) Standard Double-deep Racking Dimensions

First of all, the truth is that the depth of double-deep racking is equal to two pallets. usually every pallet is 1000 to 1200 mm deep. The height depends on the ceiling and storage needs of your warehouse. Well, you can get more storage by increasing the levels. Also, width is important because a wider rack gives you easier access.

ii) Aisle Width Requirements

Next, the aisle width in double-deep racking should be wider than that of single-deep racking. So this is necessary so that forklifts can reach the pallets at the back. If the aisle is narrow, the work will be slow and complicated. Well, you plan the aisle width according to your machines operating in your warehouse.

iii) Forklift and Reach Truck Requirements

After that, the double-deep racking needs special machinery. You can’t reach the pallets at the back with a regular forklift. So, reaching trucks gives you easy access and better time savings. Well, it is important to select the correct width and reach of your machine in advance.

iv) Warehouse Layout Planning Tips

Well, you do layout planning in advance. You need to understand the movement and frequency of your products. Store similar items together to save time and space. To be honest, this way you can maximize storage capacity. Also, make daily tasks easier. All these specialties enhance the efficiency of your warehouse and decrease errors.

4) Single Deep vs Double Deep Pallet Racking: Core Differences

As you learn about forwhat purpose you can use single deep racking and double deep pallet racking. Now you will learn the difference between single-deep and double-deep racking. Well, it is easy for you when you are planning for your warehouse.

Figure 5: Single Deep vs Double Deep Pallet Racking: Core Differences

- Comparing storage density: First of all, the greatest difference between them is storage weight. So Double-deep racking helps you to store more pallets in the same space. In comparison, a single-deep rack takes more space. But your work will be easy.

- Selectivity and accessibility: Next, the single-deep racking gives you direct access to every pallet. Well, in double-deep, only the front pallet is immediately accessible. So the rear pallet can be removed only when the front one is removed.

- Inventory flow: After that, the single-deep racking has an easier inventory flow. So you can move any pallet without removing the other pallets. Well, double-deep requires organization because the position of the pallets is important.

- Pallet Handling: Well, single-deep pallet handling is faster and more comfortable. You can use a regular forklift. In comparison, double-deep needs a truck to reach every pallet. So it can slow down your work.

- Space Efficiency: Also, double-deep racking saves your space. This is more beneficial in large warehouses where maximum storage is needed. Well, Single-deep racking uses more floor space.

- Operational Flexibility: The obvious thing is that single-deep racking is more flexible. You can store different types of items easily. Double-deep flexibility is limited. Because it depends on proper organization and machinery.

- Impact on daily operations: At last, single-deep makes your everyday processes faster. Double-dip requires a little more planning and caution. To be honest, if you have a large quantity of the same type of item. Then double-dipping is very useful for you.

5) Double Deep Racking Advantages and Disadvantages

The big purpose of double-deep racking is to store more pallets. Well, this system is especially beneficial for your large warehouses.

- Advantages of double-deep racking

Space Saving: The obvious thing is that this system saves a lot of space. So you can store two pallets deep in the same rack.

Increased storage capacity: Next, increasing storage capacity improves warehouse efficiency. Also, it helps you to store more items in less space.

Best for uniform stock: After that, this system is best for large and uniform items. Well, items of the same type can be easily stored together.

Easy access with a reach truck: At last, using a reach truck allows easy access to the pallets at the back. So, it makes handling stock in depth safer and easier.

Figure 6: Double Deep Racking Advantages and Disadvantages

- Disadvantages of double-deep racking

Limitations of quick access: First of all, double-deep racking does not provide quick access to every pallet. So the rear pallet can only be removed after the front one has been removed.

Longer handling time: After that, it is time-consuming for you to handle the stock. Also, it can be slower than single-deep.

Dependence on machinery: Next, when you use it without the right machinery and training. Then it increases the risk. Hence, incorrect use can damage your pallets or goods.

Operational hazards: At last, if you do not follow proper guidelines. So it can cause errors or safety issues for you. Well, careful planning and proper equipment are important for your safe use.

6) Advantages and Disadvantages of Single Deep Pallet Racking

On the other hand, single-deep racking is a common and simple storage system. To be honest, it is best for your small and medium-sized warehouses.

- Advantages of Single deep racking

Full pallet access: First of all, in single-deep, you have direct access to every pallet. Well, you can remove or put away any pallet immediately. So this feature makes stock handling fast and easy.

Ease of stock management: Next, keeping track of inventory is easy in a single-deep. So you can easily see the position of each pallet. Well, this system reduces errors and improves stock control.

Compatibility with common forklifts: At last, the truth is that in single-deep racking, you do not need special machinery. You can use common forklifts. Well, this reduces your operational costs and also makes training easier.

Figure 7: Single Deep Racking Advantages and Disadvantages

- Disadvantages of Single deep racking

Requires more space: First of all, the biggest drawback is that this system takes up more space. The storage capacity is less than double-deep.

Less efficient in limited space: Next, single-deep racking can be less efficient if your warehouse has limited space. But for small and diverse stocks, it is always beneficial.

7) Choosing the Right Racking System for Your Warehouse

As we know, choosing the right racking system is important for your warehouse. To be honest, the wrong choice wastes space and increases costs. Here we will discuss features that will help you decide between single-deep and double-deep pallet racking.

Figure 8: Choosing the Right Racking System for Your Warehouse

i) Assess your storage needs

First of all, you think about how many pallets you need to store. If you have a large quantity of a single product. Then double-deep can save a lot of your space. On the other hand, if you have a variety of SKUs. Then, single-deep helps you with easy entry to every item.

ii) Consider your access needs

Next, you think about how quickly you need to get to each pallet. Single-deep racking helps direct access to each pallet. On the other hand, double-deep does not allow for immediate access to the pallets behind. So it can slow down operations.

iii) Assess the available space

After that, you measure your warehouse space thoroughly. Double-deep racking works best in large warehouses where maximum storage is required. So single-deep works better in narrow aisles or confined spaces.

iv) Check machinery compatibility

Also, you also think about what forklifts and reach trucks you have in your warehouse. So, Single-deep racking works with regular forklifts. In comparison, double-deep needs a reach truck to reach the back pallets.

v) Analyze inventory rotation

Afterward, you check how many items are moved in and out. Single-deep racking is useful if the rotation of items is fast. To be honest, double-deep lowers aisle space for slow-rotation.

vi) Consider operational flexibility

Furthermore, you also think about future changes in your warehouse. Single-deep racking offers you more flexibility. Because it works nicely with different product types and pallet sizes. In comparison, double-deep racking is less flexible. Because you must remove your front pallet to reach the one behind it.

vii) Calculate Cost and ROI

At last, you examine installation and operational costs. Double-deep racking can have a higher initial cost. Because reach trucks are needed for it. On the other hand, single-deep uses more space. But forklift costs are lower. Actually, compare the benefits by balancing storage density and easier handling.

To be honest, by following all of these factors, you can choose a racking system that suits your warehouse and work style. So the right choice saves your time and money. You can use your warehouse space more efficiently without impacting workflow with careful planning,

Final Thoughts

In short, choosing the right racking system for your warehouse is very important. Single-deep racking gives you complete entry to every pallet. On the other hand, double-deep racking saves your space. But it requires planning and the right machinery. Well, understanding your stock and available space before making a decision is important for you. Hence, the right choice will decrease errors.

Furthermore, we at China Storage Rack offer you selective pallet racks to increase the productivity of your warehouse. Contact us today for more information and orders.