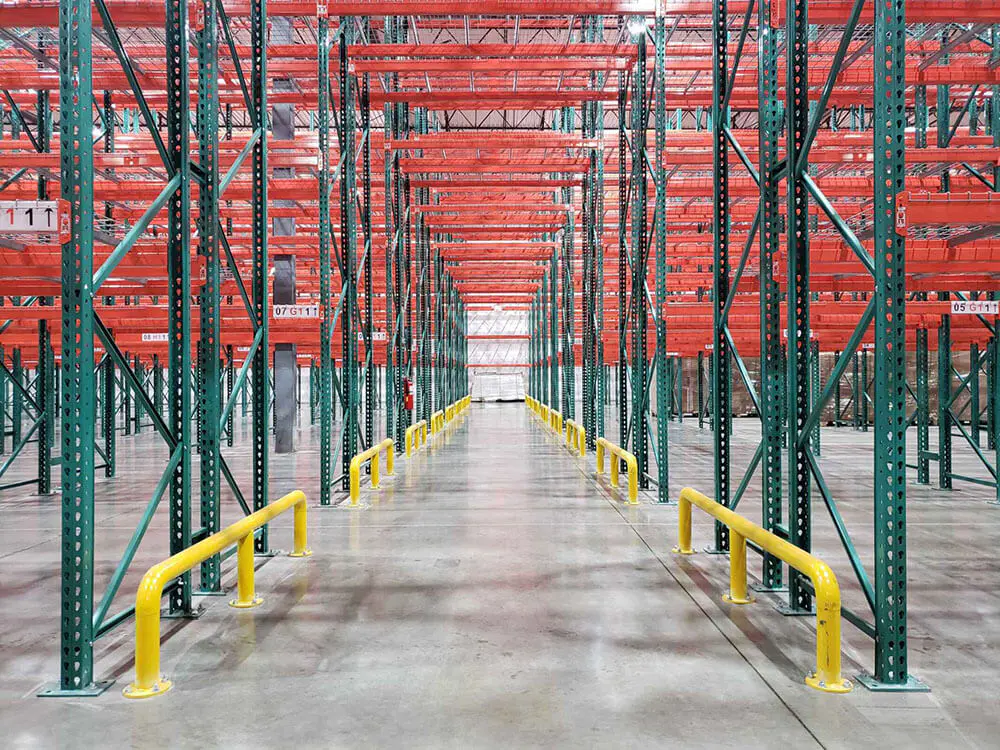

Racking is an integral part of modern warehouses. Choosing the right, high-quality racking can improve the level and efficiency of warehouse management, as well as reduce the cost of warehouse management. To choose the right racks, you first need to understand the function of racks, their classification and their related characteristics. In the face of the wide range of storage racks on the market now, how should we identify them when choosing?

1. According to the way of installation of racks, they can be classified as.

(1) Fixed racking: Fixed racking can be subdivided into rack type, pallet type, through type, gravity type, press-in type, loft type, steel platform, cantilever type, flow type, drawer type and bull-leg type racking, etc.

(2) Mobile racking: mobile racking can be subdivided into mobile racking and rotating racking, whereas mobile racking can be subdivided into light and medium-sized mobile racking (also known as dense racking, divided into manual and electric), heavy pallet type mobile racking, rotating racking can be subdivided into horizontal rotating, heavy straight rotating racking two.

2. According to the overall structure of the racks, they can be divided into.

(1) Welded racking.

(2) Assembled racks. At present, most of the assembled racks are used in China.

3. According to the structure of the warehouse, can be divided into.

(1) Warehouse racking in one type of racking. The racking system and the building roof, etc. form an inseparable whole, with the racking uprights directly supporting the roof load and the building enclosure (wall) structure installed on the uprights on both sides.

(2) Separate structure type racking. The racking system and the building are two separate systems with no direct connection to each other.

So what is different about the way these different types of storage racks are connected? Storage racks are used to carry goods all kinds of goods. Therefore the stability and safety of the storage racks have a great influence factor on the management of the enterprise warehouse.

Here is a compilation of some information about what are the different ways of fixing storage racks and how they are connected?

A. Snap is the bridge between the crossbeam and the upright piece combined together, its safety performance and strength directly affect the overall performance of the entire rack.

In racking design, there are two main types of snaps: bolt-on and snap-in.

1. Bolt connection type, is simply to bolt the snap and upright connected together, save the safety pin, but disassembly and installation are more troublesome, the bolt is also very critical to the good or bad performance of the diagonal cutting force.

2. Snapped-in is the most common connection in racking, and is very easy to install, there are two forms.

(1) Riveted also means riveted into the nail on the carabiner, the carabiner and then with a safety buckle, the upright hole is used in the classic inverted sloping teardrop hole, this type is simple to fasten, the safety buckle will automatically fasten, and the heavier the stock, the tighter the connection between the buckle and the upright;

(2) Straight buckle type, a buckle is formed directly from the snap material, and the safety pin is also taken from the snap, and the hole left can be used as the air and water outlet holes when welding and phosphating, the utilization rate is quite high, and the safety and functionality is not greatly affected.

B. The upright pieces and crossbeams in the racks are bolted or inverted riveted in two ways of connection, combined into a single group of individual racks, and then by connecting the upper sub-rack to make it the main body of the unit by row, connected by connecting the two rows to become a whole, the overall safety performance has been greatly enhanced.

C. The connection with the wall, the rack feet and the ground is fixed, in the three-dimensional racks, because the height of the rack reaches the height of the roof, so the rack will also be connected to the roof, so that the rack and the building will become a large whole, at this time the rack is not exactly an individual, but a necessary part of the warehouse.

D. The separator piece, also called the rack tie rod or rack connecting rod, is one of the regular standard accessories in the rack, and is also an important consideration in the design of the rack, for the rack. This accessory is still relatively important, it has a good strengthening of the strength, safety, and overall stability of the racks. Warehouse racking is composed of two basic elements: upright pieces, beams, and the basic racking accessories are dividers and upright protectors, and fasteners. This is the standard ordinary warehouse racking configuration, but also in the rack design must take into account the factors, and the application of the separation piece in the actual effect is very good, it plays a fixed role in the role of racks.

E. Upright frame, the racks are used to store goods, although light and medium-sized racks are generally manual to access the goods, heavy duty racks are generally used on forklifts for operation. upright protector is to slow down the impact of the forklift on the upright frame so that the racks are not damaged by a greater impact.

The racks assembled with different connection methods have different characteristics. In terms of the connection method alone, the stability of plug-in racks is very weak, bolt connection is the second most stable, and the most stable should be welding. But from the use of racks, the stability of angle steel racks is not necessarily better than that of diamond hole racks, because although angle steel racks are bolted, the bearing is small, simple structure, stability is very bad; and the plugging method has a feature that the heavier the load, the tighter the plugging, of course, to be within the bearing range of the racks, so the stability of diamond hole racks will be better than that of angle steel. Although the welding method is the most stable, now is not the most popular way, because once welded, want to move very difficult, not conducive to the continued use of the warehouse.