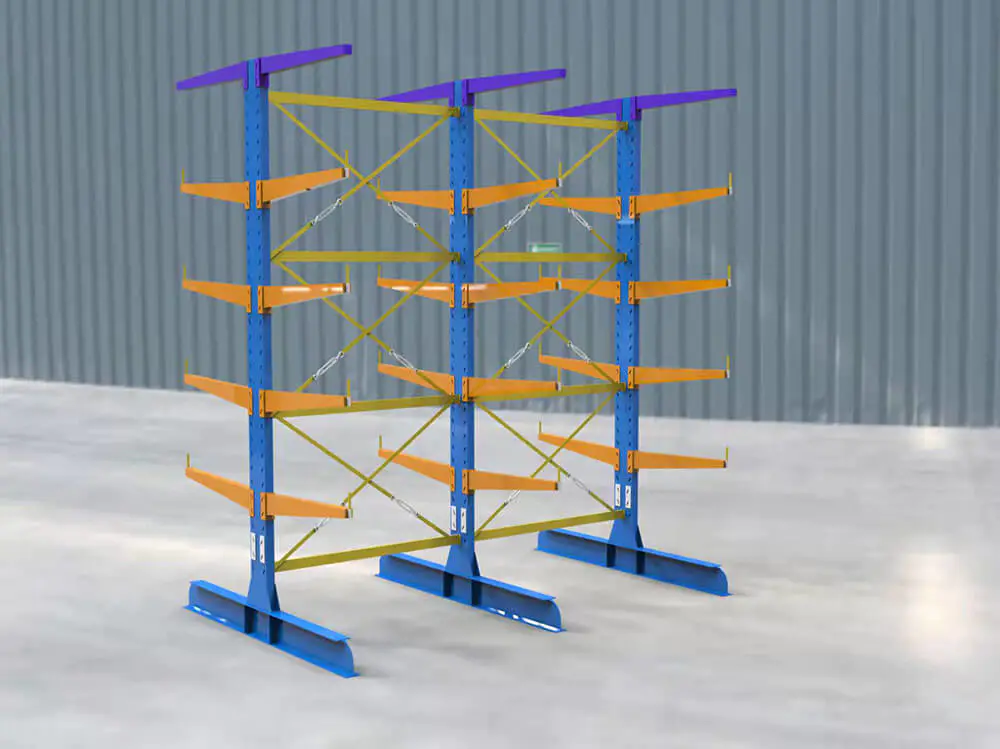

A cantilever rack is a type of free-standing storage device. They have a single vertical column supporting several horizontal arms that transport loads outward. The cantilever rack design is an important step before the installation of cantilever racks.

Cantilever racking supports objects like furniture, lumber, tubes, rolls of cloth, pipes and vehicle storage.

There are many different cantilever racking types available for a warehouse. Depending on the warehouse’s size and types of product, a specific cantilever racking system needs to be chosen for a warehouse.

Advance warehouse racking systems like cantilever racks will save a lot of time for warehouse workers.

However, if a warehouse owner has a tight budget, he can choose comparatively cheaper options like a selective pallet racking system.

A cantilever rack is one of the more expensive racking systems available for a warehouse.

We will discuss the following things about cantilever rack design step-by-step in this article:

Understanding the Cantilever Rack Design.

Cantilever racks are designed to provide a safe and secure way to store items while maximizing floor space. The design of cantilever racks is such that the arms are suspended from structural support. This allows the arms to be placed at different heights, allowing for a great storage flexibility range.

They can also be designed to store items of different sizes and weights. When selecting cantilever racks, it is important to consider the following:

- Type of items stored

- Weight of items

- Height of items

- Size of items

Properly designed cantilever racks can greatly improve the efficiency of storage. They can help reduce the risk of injury to personnel when accessing items. The components of a cantilever rack system are as follows:

- Bases that connect to the upright of the unit and serve as the major stabilizing element of the rack system.

- Columns that stand upright and join at the base. Cantilever arms are inserted into cantilever upright holes to construct the storage levels. Uprights can be used with single-sided and double-sided units.

- Arms are used to store the merchandise that is attached to the uprights. The “shelves” are made of cantilever arms.

- Braces that provide horizontal and diagonal support to sustain the upright columns. Cantilever bracing is used to structurally link and support the uprights.

- The cantilever storage arms are supported by decking that, when needed, offers a solid shelf level.

Considerations For A Cantilever Racking Design.

Given that it was designed for storing long, heavy items like wood, pipes, or textiles, cantilever racking is the best storage solution for a variety of sizes and shapes of commodities. Inventory is moved from the warehouse floor or yard to arranged, accessible shelves using cantilever racks.

When designing a cantilever racking system, there are several important considerations to keep in mind to ensure the racking is safe, functional, and meets the needs of your business. Here are some of the most important considerations:

- The cantilever racking system must be able to support the weight of the items being stored and any additional loads.

- The size of the goods to be kept and the available space will determine the height and breadth of the cantilever racking. Without sacrificing safety, the height and breadth should be constructed to match the available area and the things to be stored.

- The size of the objects to be kept will determine how long the cantilever racking arms are. Longer arms can store longer objects, and shorter arms are better suited for storing smaller objects.

- The cantilever racking is stabilized with bracing. To avoid the racking system from toppling over from the weight of the stored things, bracing must be incorporated into the design.

- The base plate is a crucial element in the construction of cantilever racking because it serves to evenly distribute the weight of the objects being stored. Based on the weight of the goods to be kept and the surface on which the racking will be put, the base plate’s size will be determined.

- The cantilever racking’s structural construction must be robust enough to support the weight of the goods being stored. The racking system must be made of sturdy, long-lasting materials.

- When developing a cantilever racking system, safety must come first. Items should not be allowed to fall off the racking and harm people or cause property damage, hence the racking system should be built to avoid this.

- It’s crucial to consider accessibility while designing the racking system. The objects kept in the racking system should be simple for employees to reach without putting themselves in danger.

- If not created with fire safety in mind, cantilever racking may provide a fire risk. The racking system needs to be built to reduce the risk of fire and make it simple to reach firefighting supplies.

Safety Practices of Cantilever Racking System

There are various recommended practices regarding the safe usage of the cantilevered rack. This is regardless of whether it is installed inside or outside.

A cantilevered rack should, at the very least, undergo an annual inspection. For cantilever racking inspection, Mracking is a leading company. We have expert people who are well aware of the technicalities of the cantilever racking inspection.

Racks in heavy traffic locations or those with past damage should undergo more frequent inspections. When a damaged area is found, the rack has to be separated and emptied when it’s safe to do so.

While adding or removing weights, caution must be exercised to prevent an upward or downward impact. This may cause the arm to become detached from the column or disengage it.

Long cargo is typically kept on a cantilevered rack. Because of this, they frequently sag when being installed or removed. The rack installation may call for the employment of a particular attachment or piece of material handling equipment. This is to provide additional support.

How To Design Cantilever Racking?

The material that will be utilized to construct the racking system is the last thing you should think about. Based on the objects that will be stored and the required racking system longevity, this should be decided.

Depending on the available space and capacity, cantilever racks can be either single-sided or double-sided. A cantilever racking system’s modular design makes it possible to add or remove extra arms, uprights, and bracing as storage needs vary.

The design should include arms, upright columns, bases, bracing, and base plates. The main part of design is comprised of three parts. These are arms, uprights, and braces. You may start designing the cantilever racking system once the capacity, size, levels, and materials have been established.

Arms

The heart of the rack system is the arms. An effective storage plan might succeed or fail based on proper selection. Count the number of arms needed to sustain your load. The depth of your burden is equal to your arm’s length. Uniform loads are the foundation for arm capabilities.

You just need to choose whether they should be straight arms or inclined arms once you’ve calculated how many arms you need.

- Straight Arms are typically used to store stable cargoes like skids, steel sheets, timber, and cartons.

- Slanted arms are Often used to store cylindrical weights or objects with a tendency to slide forward

Uprights

A horizontal base that is attached to the column and a vertical column make up an upright. To create a storage bay, a minimum of two uprights must be bought. Single- or double-sided uprights are both possible.

By dividing the desired number of arm levels by the capacity of the chosen arms, you may calculate the upright capacity. Although weight can be kept on the base, this load is not included in the upright capacity.

The height limit of the upright is influenced by the ceiling height, truck reach, suppression systems, as well as other factors including local building codes.

Decide on the required number of layers and the height of the items you wish to store. Your product’s top must be at least four inches from the bottom of each cantilever arm.

Each level of the system’s arms will need a specific quantity of room. Due to the various capacities required, cantilever arms exist at a variety of heights. The typical height is between 3 and 4 inches.

As a general guideline, the top of the cantilever upright should be 4 to 6 inches higher than the highest point of the item being housed. The appropriate height for your product will be determined by adding these three factors together.

You must first establish the height of your cantilever uprights and then their capacity, or the amount of weight they can support. Multiplying the number of arms per side by the load on each arm yields the necessary capacity.

Cantilever Brace

In order to give the rack system lateral stability, brace sets structural channel members are bolted between pairs of uprights. From the midline of one upright to the centerline of the next upright, a brace’s width is calculated.

Base

A crucial element that ensures the stability of the racking system in a cantilever racking design is the base. The foundation spreads out the weight of the stored goods over the floor.

The racking system’s foundation has to be constructed such that it may be put on any surface.

While designing the cantilever racks, the local building code rules and regulations should also be kept in mind too.

So, this is everything you need to know about the cantilever rack design. Comment down below if you have any questions related to the cantilever rack design.