Useful materials are vital for any mezzanine flooring. Picking the right steel makes your floor safe and long-lasting. Have you thought about which steel is best for your mezzanine and why different sections are used?

In this article, we will discuss what materials are used in steel mezzanine floors and what their characteristics are. We will also discuss how they affect strength. From cold-rolled steel to stainless steel, we will explain everything that will help you make the right choice. Keep reading!

Figure 1: Mezzanine Floor Racking

1) Importance of Material Selection in Mezzanine Racking

When you are planning a mezzanine floor, the choice of material is very important. Because it affects the strength and stability of the structure. Selecting the right material guarantees that your floor can resist the weight. It is designed to carry, including equipment, tools, and people.

Therefore, if you use low-quality materials, problems like structural failure can quickly appear, which can affect safety and performance. It is important to understand how different materials affect mezzanine racking, so that your installation is safe and long-lasting.

Figure 2: Importance of Material Selection in Mezzanine Racking

i) Impact on load-bearing capacity

First of all, every mezzanine floor holds a large amount of weight. If your material is weak, the floor can fail under pressure. On the other hand, strong steel helps you handle heavy loads safely and distributes the weight across the beams and columns.

Also, this proper distribution decreases stress at critical points. It increases overall stability. Picking the right material guarantees that your mezzanine can safely support the weight of your products and personnel.

ii) Safety and durability

Next, safety is always your top priority in a warehouse. Using high-quality materials decreases the risk of accidents like cracks, bending, or sudden failure for you.

Furthermore, durable steel can resist the vibrations caused by daily use and movement. It also resists the impacts of forklifts and machinery. Which means you have to face fewer repair issues. Your workers feel more confident and safe because they know that the structure is stable and dependable.

iii) Long-term performance

Then, the choice of material affects long-term performance. High-quality steel lasts for many years and does not lose its strength when carrying heavy loads. It also resists wear, fatigue, and rust, which decreases maintenance costs.

Therefore, your mezzanine continues to deliver reliable performance with minimal downtime. Selecting the right material not only guarantees your safety but also saves your money by keeping your business operations safe in the long run.

2) Main Materials Used in Steel Mezzanine Floor Racking

As you learn, the material you choose affects strength and long-term performance. There are three types of steel used in steel mezzanine racking: cold-rolled steel, hot-rolled steel, and stainless steel.

Well, each type has its own advantages and specific uses, depending on the weight, environment, and structure design. Comprehending these materials will help you make the best choice.

a) Cold-rolled Steel

First of all, cold-rolled steel is rolled at room temperature. This process makes its surface smooth and uniform. This makes it stronger and harder than regular steel. Its smooth surface can also be easily coated, which protects it from rust.

Moreover, you can use cold-rolled steel to make beams, shelves, and parts of racking that need accuracy. It performs well for medium loads and offers you stability. It is also a dependable choice for many standard mezzanine structures.

Figure 3: Cold-rolled Steel

b) Hot-rolled steel

In contrast, hot-rolled steel is rolled at a higher temperature. Its surface is rougher than cold-rolled steel. It is much stronger and can resist heavier loads. That is why hot-rolled steel is ideal for heavy mezzanine floors.

Furthermore, you can use it for main beams, columns, and frames where strength is more important. It is also cheaper for your large projects. Because it can be manufactured in large sizes. Its strength makes your mezzanine safe and long-lasting.

Figure 4: Hot-rolled steel

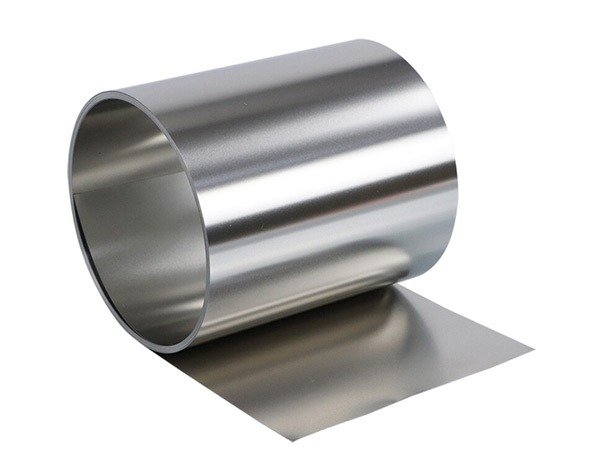

c) Stainless steel

Then, stainless steel is resistant to rust. For this reason, it is better in harsh conditions. For example, you use it in high-humidity areas. It also stays practical around chemicals. That is why it is perfect for food warehouses. Additionally, it is also suitable for use in chemical storage areas. It also protects your discreet items. So, it requires less maintenance.

Figure 5: Stainless steel

Furthermore, stainless steel is costly compared to other steels. However, it is still a useful choice for you. It is also suitable for places where flawless is important. But it also provides strong performance. Therefore, all three materials are used for specific goals.

- Cold-rolled steel offers you accuracy.

- Hot-rolled steel offers you strength for heavy loads.

- Stainless steel gives you rust protection and cleanliness.

So you should pick according to your weight requirements, environment, and budget. Because selecting the right steel makes your mezzanine floor safe and economical. Picking the right material affects the performance of your warehouse. Well, knowing these materials will also help you create a long-lasting mezzanine floor.

3) Structural Steel Sections Used in Mezzanine Floors

Afterward, steel structural sections are the base of the mezzanine floor. Picking the right section guarantees strength. Because different steel sections are designed for different uses. The common sections in a mezzanine floor are I-Section steel, H steel, and H beam.

Well, channel and angle sections are also used for support and framing. Understanding these sections will help you build a safe and long-lasting mezzanine structure.

Figure 6: Structural Steel Sections Used in Mezzanine Floors

- I-Section Steel

Next, I-Section steel, also known as an I-beam, is shaped like the letter “I”. This design offers you excellent load-bearing capacity and keeps the weight of your steel low. I-Sections are also ideal for beams and frames. They distribute the weight across the floor and control it from bending under big loads.

Furthermore, you can use I-Section steel for medium to large spans where strong support is needed. Its design helps with easy attachment to other structural components. So this forms a process more manageable.

- H Steel

Then, H steel is similar to an I-Section but has wider flanges. This gives it greater stability and strength. It is used in the mezzanine floor central supports. The wide flanges also control it from twisting and bending under heavy loads.

Furthermore, H steel can effectively resist vertical and horizontal forces. It makes it suitable for load-bearing and framing. Its strength keeps your mezzanine floor stable despite moving weight.

- H Beam

After that, H steel beams are heavy-duty steel sections with wide flanges. They are designed to carry a lot of weight and are used in industrial mezzanine floors. H beams are ideal for heavy structures where more support is needed.

Also, their wide flanges help you with easy attachment to other structural parts, like beams and braces. So using H beams helps your mezzanine floor to carry burdens without structural issues.

- Channel sections

Also, channel sections are C-shaped and are used for secondary supports and frames. They are lighter than I-beams and H-beams. But they offer you strength. You can use channel sections for small beams, edge supports, or bracing. Their shape enables you to easily connect to other steel components.

Furthermore, channels help you to balance the floor weight. They also offer you extra strength.

- Angle sections

At last, angle sections are L-shaped steel pieces used for reinforcement and bracing. It is also used for joining parts. They are also flexible, and you can utilize them in corners, supports, and frameworks. Angle sections offer you additional strength and prevent bending and twisting. They are also helpful in connecting mezzanine floors to walls. Well, angle sections work with I-sections, H steel, and H beams to increase support.

Furthermore, picking the right steel sections makes your mezzanine floor safe and long-lasting. I-Section steel provides effective weight distribution for beams; H steel and H beams carry heavy vertical loads. While channel and angle sections supply extra help and strength. Picking the right sections helps to make a high-performance mezzanine floor.

4) Factors to Consider When Picking Materials

Well, picking the good material for a mezzanine floor is not limited to just picking steel. Many factors affect performance and cost. If you consider the right characteristics, you can make the best decision. Now we will examine vital factors.

Figure 7: Factors to Consider When Choosing Materials

i) Load-bearing capacity

The first factor is the load-bearing capacity. You need to know how much weight the mezzanine will support. This includes equipment, tools, and people. The material must be strong to safely support the weight you need to store. If the steel cannot support the weight, the supports can break. Picking the right load-bearing material keeps your floor safe.

ii) Span and height requirements

The next factor is span and height. Span guides the distance between supports, and height guides the upright space. Long spans need stronger and thicker steel sections to control bending. Tall mezzanines need steel that is resistant to bending. Proper span and height planning make your floor effective.

iii) Environmental conditions

After that, environmental conditions also affect material selection. Think about moisture, temperature, and the effects of chemicals or water. For instance, stainless steel is best for humid or corrosive environments. Cold-rolled or hot-rolled steel works well in dry, normal conditions. Selecting a material for your environment will prevent rust and extend the life of the floor.

iv) Budget

The budget is also an important factor. High-quality steel is costly at the start. It saves money in care and safety. Cheaper steel will often need repairs and replacement. You need to offset the starting cost with the long-term benefit. The right budget will also make it possible for you to create a safe and long-lasting floor without spending too much.

v) Maintenance requirements

Furthermore, maintenance is also important, but usually overlooked. Some materials need extra maintenance. For example, stainless steel needs less maintenance, while other steels require coating or regular inspection. Selecting a low-maintenance material keeps your time, work, and costs. Proper care keeps the floor safe and functional.

vi) Compliance with standards and regulations

Finally, consider construction regulations and protection measures. Your materials should comply with regional laws, like strength, fire protection, and safety standards. Using approved materials guarantees your mezzanine passes inspection and lowers legal liability. Compliance with regulations also ensures that the floor without keeps the expected weight.

Moreover, by thinking about weight capacity, span, height, environmental conditions, budget, maintenance, and observation with rules. You can pick the good material for your mezzanine floor. This makes the floor safe, strong, long-lasting, and economical. Planning also controls future problems and helps create a reliable mezzanine floor.

Conclusion

In short, picking the right materials and steel sections is important. This keeps your mezzanine floor safe and strong. Taking weight, span, environment, and budget into account also helps you in more useful planning. Your floor will last longer.

At Mracking, we offer you high-quality mezzanine floors and racking solutions. You also get strong and dependable products. They are customized to your area and weight requirements. So you can trust our solutions.