WhatApp: +86 13713386306

Email: nancy@chinastoragerack.com

Phone: +86 18578478231

WeChat: +86 18578478231

A pallet shuttle is a semi-automated storage solution that is used in warehouses to load and unload pallets, It needs to be used in conjunction with shuttle racking. It eliminates the necessity for forklift vehicles to enter the aisles, thus saving money and time. The pallet shuttle system enables automatic stock control by counting the amount of stored pallets using sensors.

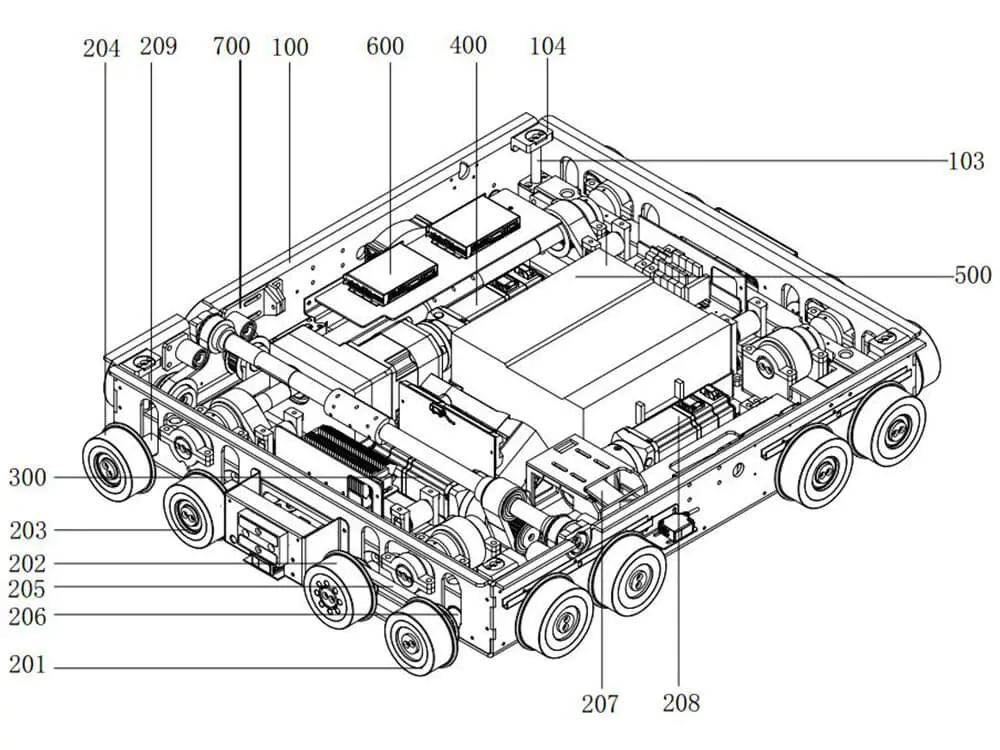

To visualize how the pallet shuttles work, it is very important to know about the components/ parts of the pallet shuttle system. Here is a brief description of the main parts of the pallet shuttle system parts:

Beam

The rails in the pallet shuttles are supported by the beams. It allows the shuttles to move horizontally.

Upright

These vertical parts are flexible enough to accommodate a variety of load needs.

Wheels

Wheel helps the shuttle travel efficiently with the inner lane and enables it to transport the cargo.

Pallet Shuttle Remote Control

This is the pallet shuttles fundamental control mechanism. The operator utilizes it to signal the necessary operating capacity. The information screen and control buttons in the pallet shuttle remote control make it easy to operate.

Shuttle Rails

This is a piece of metal that allows the pallet shuttles to go down the aisle. It is supported by the beams and the supports that go with them.

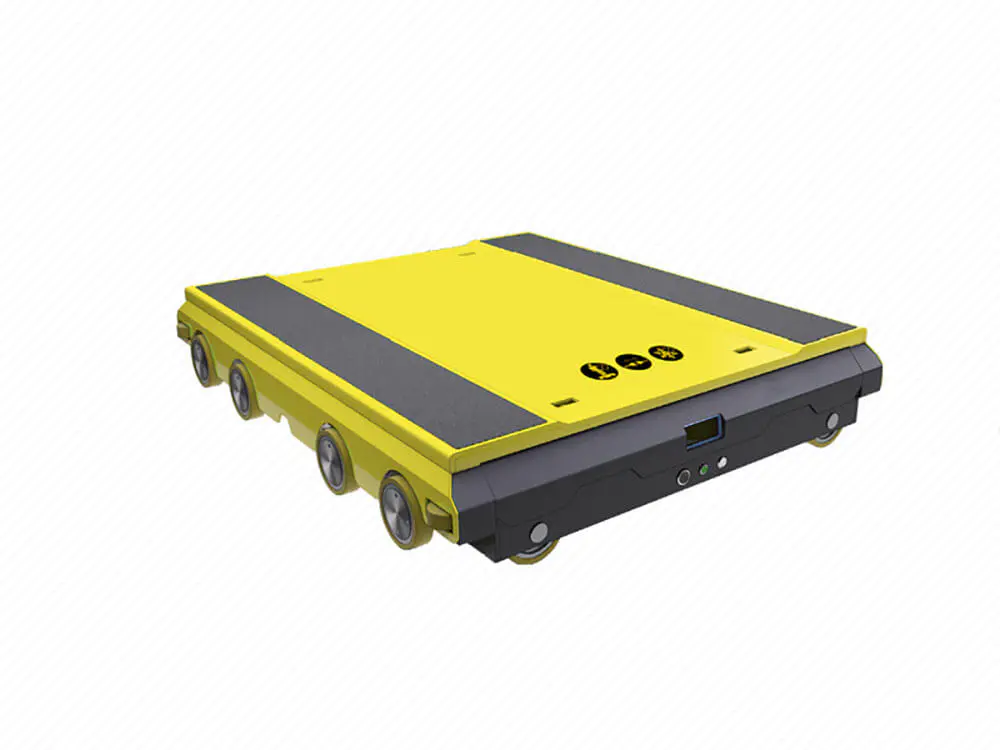

Shuttle Of The Pallet Shuttle System

It is a base platform with wheels to allow for movement. A large number of sensors and detecting readers that gather data from their surroundings and enforce safety measures make up this system.

Different status indications are built within the shuttle itself to let the operator know the following things:

Rail Backstop

It is the component that serves to alert the shuttle to the finish of the rail. Its function is to alert the shuttle to the rail’s end and turn on its braking mechanism.

Safety Bumper

It is used to avoid probable crashes or congestion.

Galvanised Frame

Galvanised frame is one of the primary parts of the racking. It consists of the following things:

Pallet Guidance

Pallet guidance can be found at both the beginning and finish of each level. It makes it easier to deposit the unit loads along with keeping them from deviating from their intended path.

Rail Supports

This part holds up the metal rails that the pallet shuttle travels on. The entrance as well as the exit uprights of the aisle serve as anchor points for the external supports. At the same time, the internal supports are fastened to the internal supports.

Recovery Platform

A shuttle or load can be safely removed from the rack using the recovery platform. It is manually operated. It enables rescue crews to reach a damaged shuttle by moving down the channel. A hook can be used to tow the damaged shuttle out of the channel.

Lifting Platform

Pallet movements are made easier by this mechanism, which raises pallets using the platform.

Workplace accidents are a great concern for the owners and managers of the warehouse. With the use of a pallet shuttle system, workplace accident rates can be reduced to a great extent. Some other benefits of the pallet shuttle system are as follows:

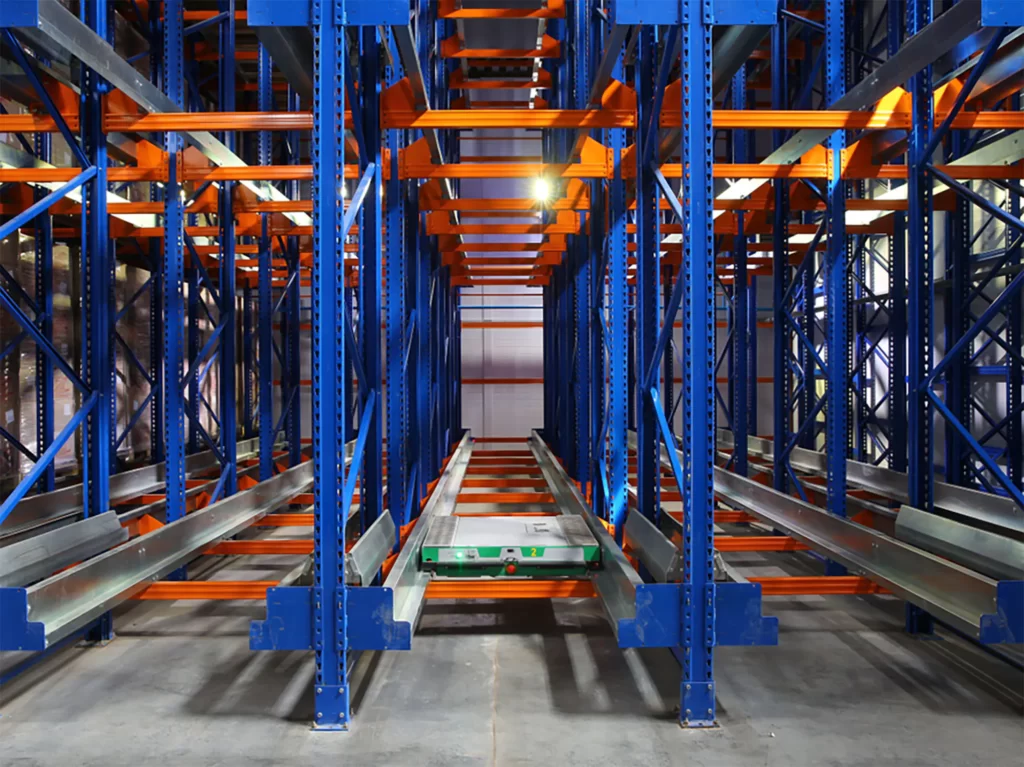

The pallet shuttle system is controlled remotely. In this system, pallets in the rack are moved using independently powered shuttle carts. With the help of the remote-controlled system, the pallet shuttle system continuously loads and retrieves pallets automatically.

The operator of the Pallet Shuttle uses a tablet with a Wi-Fi connection to send commands to the Pallet Shuttle. The load is then deposited in the channel’s first open space, with the pallets being packed as tightly as possible.

Till the rack is completely loaded, either the unit loads are positioned on the first accessible position, or, until the rack is completely unloaded, items are taken from their storage areas and transported to the front where a forklift vehicle is waiting to pick them up.

The pallets are then placed there when it is moved along the route till it meets the first open spot. When the next driving cycle is ready, it returns to the start of the lane.

Both FIFO and LIFO management is possible with the Pallet Shuttle system. However, the LIFO management system is more popular. Because the LIFO management system requires using one end of aisles for the loading as well as unloading of pallets. The first pallet that will enter the system will also be the first pallet to leave, completing the FIFO management cycle. To simplify the process, now we will break down how the pallet shuttle system works in 8 easy steps:

| Name | Cost | FIFO,LIFO | Amount of goods and size in the warehouse |

|---|---|---|---|

| Pallet Shuttles | $185-$250 for each pallet | Works both in FIFO and LIFO modes | Suitable for when there is a massive amount of goods and the size of the warehouse is big |

| Selective Pallet Racking | $46- $60 for each pallet | Work in FIFO only | When the warehouse is comparatively small and has a small number of goods |

| Double Deep Pallet Racking | $55- $65 for each pallet | Work in LIFO only | When the warehouse is comparatively small and has a small number of goods |

A pallet shuttle is ideal to use in low-temperature storage solutions. It can work up to -30°C. This system is the best option for managing large numbers of pallets with a single SKU. It is also appropriate for heavy loading and unloading operations. Apart from that, it is ideal to use a pallet shuttle system in the following scenarios:

There are some scenarios where it is better not to use the pallet shuttle system, and instead, use other types of racking systems. These types of scenarios are as follows:

Pallet shuttles cost around $185-$250 for each pallet.

We will take around 15 days to manufacture the products. And the delivery will depend on the time of transportation after we have manufactured it.

Our shipping method is by sea as our products are heavier.

Depending on your budget, when you have enough budget, using one shuttle per layer will make your storage work easier and more efficient.

We have more than 16 years of experience manufacturing pallet racks.

We manufacture the pallet racks by ourselves in our factory located in Dongguan, Guangdong, China.

Mracking uses excellent quality materials to build our products. Additionally, we offer 20 years warranty on its pallet shuttle service! We are super confident in the quality of the product we build and that’s why we offer this extensive guarantee period.

Apart from selling pallet shuttles, we also offer installation support for our customers.

We also provide inspection service for the pallet racks.

Our customer support is open 24/7/365 for our customers.

You can order a customized pallet shuttle system for your warehouse too according to your specific needs. We have an experienced team of experts leading our racking system manufacturing.

Your email is absolutely secure and we’ll not disclose it to any third party for any reason.

Your email is absolutely secure and we’ll not disclose it to any third party for any reason.