One effective method for maximizing space in current facilities is through the installation of pallet racking. Experts in warehouse management and operations concur that utilizing vertical space benefits all parties involved. This approach allows for improved operational management and organized inventory storage.

But what if you desire alterations to your racking setups? Absolutely! You have complete control over your racks, allowing for any desired variations. The pallet racking configuration is designed to accommodate all user requirements and specifications.

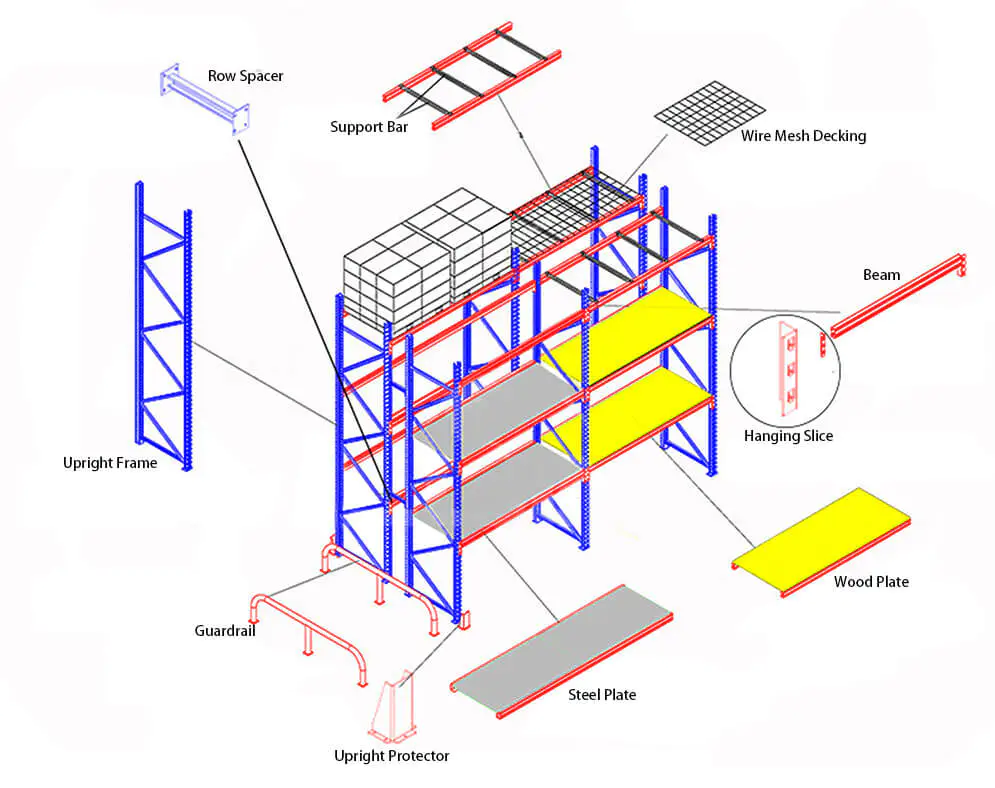

In this article, you’ll learn more about these racks. Now, let’s delve into pallet racking configuration.

What Is a Pallet Racking Configuration?

Pallet racking storage system has been used for years now. But the concept of pallet racking configuration can sound new to many. Pallet racking configuration refers to the precise configurations and designs of the racking system that can change depending on the situation.

The factors that should be considered for pallet rack configuration are:

- The type of goods to be stored

- Total available space

- The equipment used to handle the pallets

- Reduce clutter

- Streamlined picking

- Easy handling

- Weight of the goods

- Dimensions of the pallets

- Height of the storage area

Using pallet racking configurations can help you to surge productivity. The immediate results of customizable configurations can be seen through effective operations that promote a good image of an organization.

If the pallet racking is installed properly then it can save you from any mishandling of goods, increases the storage capacity, enhances efficiency, and the workers will be at less risk of injuries.

How to Configure Pallet Racking Systems

There are many steps involved to understand and measure pallet racking. But if you are just looking to configure your pallet racking system then here are the process of the following steps to help you set up your pallet racking.

So, let’s get going on how to configure the pallet racking system.

Step 1: Measure the Size of the Product

First of all, start by measuring the width, height, and depth of your pallets. Typically, the pallet’s size is 40’’ wide x 48’’ deep. It is recommended to leave a little space between the pallets, so that, it will be easier to load and unload the rack. Keep track of the measurements because further, it will be helpful for the coming steps.

Do not forget to take the measurement of the heaviest load item you will be storing. Add the pallet weight to the heaviest load item’s weight. It is important to determine the overall weight so that you will have a complete size for configuration.

Step 2: Select Beam

Now, based on the previous measurements, you need to determine the width of the shelve that you require. For instance, with a typical pallet, the load on the shelf might be 80’’ (considering two pallets per shelf). You will be needing a minimum of 96’’ beam for a 4’’ on each side of each pallet.

Once your rack’s width has been determined, now you need to select the right capacity beam for the load, where each shelf and rack level might require two beams.

Step 3: Choose Upright Sizes

The third step in pallet racking configuration is to determine the height and depth of uprights. It is a simple yet important step where you figure out how many shelf levels you want. Considering the pallet height, you can rightly manage the upright height.

When you choose the right upright, it is recommended to take both load and total shelf capacity into account. However, the depth of uprights will be based on the depth of the pallets. What you need to do is to create a balance between the entire pallet load on the front and rear rack beams.

Step 4: Adding Up all the measurements

Now that you have determined the total number of beams and uprights correctly; you have a clear mind to plan a storage system. It is important to note that one upright shall be used as a connector for the multiple bay racks. Also, two racks can share a center upright. But remember, this can be done when total shelf and upright capacities are within range.

Important Things to Consider for Pallet Racking Configuration

Is the storage capacity bothering you? Need more space and don’t know where to pick? Then we have some important things to tell you about pallet racking configuration.

There are many factors that should be considered while you design pallet racking. Whether you want a configuration for your existing pallet racking or you want to create a new pallet racking system, every detail is important. So, make the most out of the things that you are already using for the storage system.

By configuring your warehouse pallet racking system, you ensure its safety and security. Moreover, conducting regular measurements and adjustments can help you proactively mitigate potential costs and avoid future complications. It’s a wise investment that safeguards your operations and saves you from unforeseen troubles down the road. Here are the factors that should be considered for pallet racking configuration.

1. Understand the Racking Run

Determining the right storage system becomes easy when you start with the length of the racking run which is ideal for your racks. Sometimes, it might be equal to the warehouse length or the floor space that you will be using for the racking. Therefore, calculate the exact number of runs which you require in actuality. For easy understanding, calculate the run for one racking and then you can go along with others.

Determining the right storage system becomes easy when you start with the length of the racking run which is ideal for your racks. Sometimes, it might be equal to the warehouse length or the floor space that you will be using for the racking. Therefore, calculate the exact number of runs which you require in actuality. For easy understanding, calculate the run for one racking and then you can go along with others. In order to understand the pallet racking run in a better way for the configuration, consider the guide of pallet racking to have a clearer view.

2. Determine the Pallet Requirements

It is important to plan how many pallets you want on the rack, the storage load it will take, and how much space it will acquire in your system. Now is the time to measure the height and length of the beams.

Consider your inventory requirement and plan how wide you want your racks like one pallet or maybe more. Whatever rack width you choose, there is no right and wrong answer to that. Just plan the right storage system that will help you store enough items.

3. Sizing the Pallets

As we have discussed earlier the process to configure the pallet racking now the sizing of pallets is a little more descriptive than before. According to the GMA (Grocery Manufacturer Association), the pallet is 48’’ deep and 40’’ wide, in general. But there are many other sizes available. So, you can plan your pallet racking according to the size you require as per the need.

In order to do so, you need to measure the actual pallet then you can determine the height of your pallet. Also, the height of the load should be considered when determining the height of the pallet. This is how you can get a clearer picture of the actual height of your pallet racking. This way it will be easier for you to count the number of beams that can fit into such height.

The construction of the pallets and the type of pallet you are storing will help you determine the pallet size. In addition, the pallet weights are also important when planning a pallet size. Because the weight of the pallet will directly influence the following factors:

- Frame specifications

- Beam capacity

- Rack configuration

- Warehouse floor load weight

Communicate with your executive team comprising the warehouse manager and other related personnel to get things properly done. Discussing more with concerned people might take a little longer. But details should be discussed to manage costs and safety.

4. Measure the Beams

You can determine your beam length through the run length. Following are the standard beam lengths:

- 8 feet

- 9 feet

- 10 feet

- 12 feet

The above-mentioned beam length is the most common one but there are many other length options that you can choose for your racking. Every manufacturer has their own beam sizes so you need to work according to your space system.

Here is an important point while measuring the beam: are you installing a new racking system or do you want to replace the existing rack? Extra cautions are required if you want to replace the existing one.

Sometimes, the measurements are taken from the outside of uprights which turns out to be incorrect. So, you ensure that the measurements are taken inside the edges.

In the case of installing new beams, focus on every detail that has been discussed during the information gathering so that you have an accurate beam length.

5. Measure the Rack Depth

The rack depth can be measured by measuring the width of the uprights to which the beams will be attached. You may need to allow a 3″ overhang on the front and rear of the rack when measuring the depth of the rack in some circumstances.

It will be a total of 6’’ extra as we are calculating the depth of the rack from front and back. Therefore, you will be subtracting 6’’ from the actual depth of the pallet. So that your rack depth will be deep enough just like you want it.

Taking an example of a standard pallet depth which is 48’’ deep. So, you will be needing a 42’’ deep rack. 3’’ of overhang will surely improve pallet accessibility and make it much easier for forklifts to access the pallets.

You don’t have just a 42’’ deep pallet rack option but there are many other depths with the following dimensions:

- 24’’

- 36’’

- 44’’

- 48’’

All these dimensions can vary with the manufacturer you choose. Just remember to measure the beam length from the edge’s inside. However, in this particular case, you will be measuring from one outside edge to the other outside edge while using uprights.

6. Measure the Rack Height

The optimal use of the racking system configuration is to select the right height for your rack. The height of the rack can reach the ceiling to utilize the pallet storage to its fullest. But one limitation can take you back from this decision.

You can design a racking system that can reach your warehouse ceiling but you need to check whether the forklifts have enough reach to get the pallet from that height. This is known as equipment limitation which should be considered in warehousing.

Following are the things to consider when calculating the rack height:

- Dimensions of tallest pallet load: measure the highest pallet load with the height of your current pallet load between the elevations. This calculation will allow accounting for overhead clearance. So, it will be easier for forklifts to access the rack.

- Dimensions of pallet height: when you are not sure how many levels your rack system could take then the tallest reach can determine that. The highest reach can either be your ceiling’s maximum height or your forklift’s reach. Divide this number by the level of spacing, this way you can get a clearer answer to the question.

7. Compiling All The Measurements and Configuring the Calculations

Now that all the work is done and finally it is time to calculate all the measurements by compiling them together. You need to determine the rack’s total run length so that your racking run will fit in your footprint. For such a purpose, you need to calculate the beam length and your upright width. The width is usually 3’’.

Compile all the above beams, height, and width of the racking system. It will be a complete guide for the pallet racking configuration.

Conclusion

Pallet racking configuration can be crucial for warehouses but the right racking configuration can either make your profits. Using your space within the facility or maximizing the storage capacity can be difficult but believe us, it surely makes a difference. It promotes ease of access, efficient use of space, and safety.

Remember that pallet racking configuration is not a one-and-done endeavor; it is an ongoing process. It necessitates continual adjustments, regular maintenance, and safety checks. Adhering to these practices can prevent potential accidents and ensure a safe working environment.

In a nutshell, we will advise you to invest in your pallet racking system because it is worth your time and will lead you to a profitable organization.