Do you have a new warehouse that needs warehouse racking layout design? Or do you want to optimize your existing warehouse racking layout to improve storage efficiency? Read on, this article will help you solve your problems related to warehouse racking layout design. To save you time, I’ve put together a table of contents that you can click on below to jump to the places you’re interested in.

Why Need Warehouse Racking Layout Design?

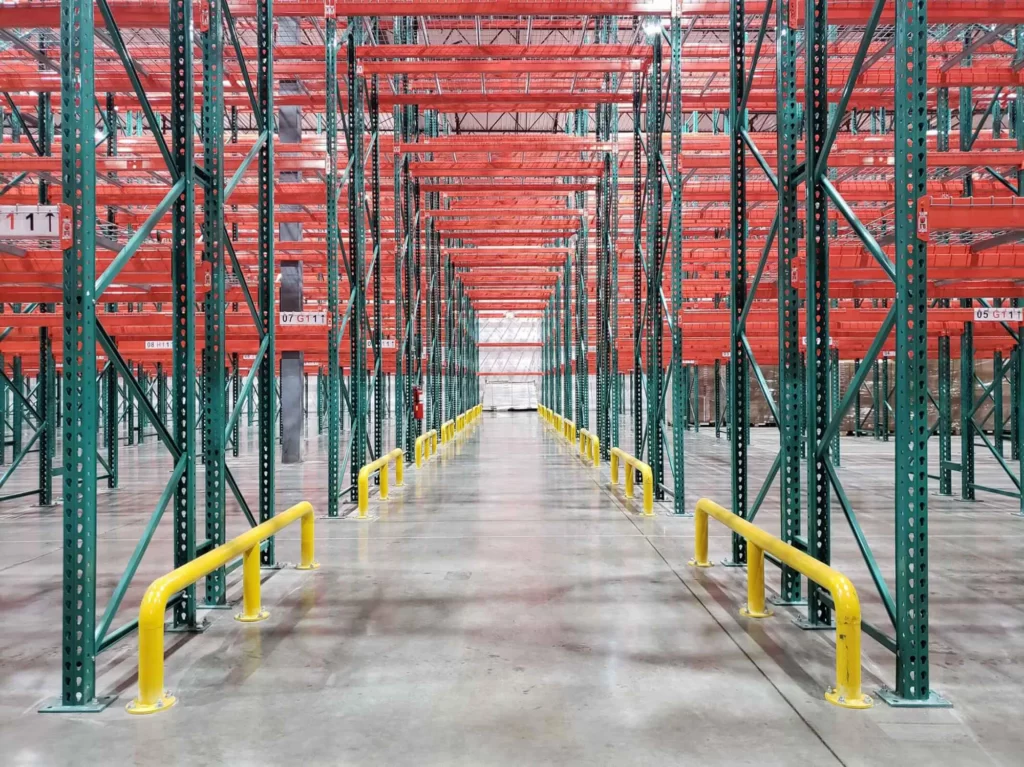

A warehouse is a place of business where materials or products are stored and usually has a high turnover efficiency. A good warehouse layout design helps you to keep your warehouse well organized, while a bad warehouse layout can make warehouse picking chaotic and inefficient. A proper pallet racking design layout not only helps to improve access efficiency, but also saves companies a lot of money in storage costs.

Efficient warehouse storage systems rely on different types of pallet racking, material handling equipment, and computer control systems, with the most important influencing factor being the warehouse racking. By designing the layout of warehouse racks can be achieved to maximize the use of floor and vertical space, at the same time, access to the location of goods, inventory access types, work areas, aisles are also clear at a glance, convenient for warehouse managers to manage and control costs.

Proper warehouse racking layout design has several benefits.

- The correct pallet rack design makes access more convenient, which can improve efficiency and save storage costs.

- Proper pallet racking design layout makes inventory management more convenient.

- Making full use of the vertical space of the warehouse significantly increases storage capacity.

- The goods are neatly stacked to improve the safety of operation and reduce safety hazards.

- Avoid collision or extrusion, effectively guaranteeing the quality of products.

- A clean and tidy warehouse helps to enhance the image of your business.

How are the aisles designed? What type of forklift is used? Before proceeding with your storage work, it is best to spend some time planning for your warehouse layout. Follow our guidelines to get a good understanding of your warehouse, products, storage processes and storage needs to design an ideal warehouse racking layout plan.

The Elements To Be Considered In The Layout Of Warehouse Pallet Rack Design Layout.

1. Pallet size

Pallet dimensions (length, width, height) are the more important measurements when designing pallet racking layout. The dimensions of the pallet help determine the dimensions of the pallet racks, such as the length and depth of the rack. We commonly have three sizes of standard size pallets: L1200*D1000*H150mm, L1000*D1000*H150mm and L1200*D800*H150mm.

You need to measure the length, width, height and weight of your stored products and choose the right size pallet according to your stored goods, so that you can design the length and depth of the pallet rack correctly. Take a beam type pallet rack as an example, usually two pallets are placed on each level. When designing the length of the pallet rack, a safety distance of 100mm will be pre-set between the pallet and the adjacent pallet, and similarly, a safety distance of 100mm should be set between the pallet and the racking upright as well.

From the safety point of view, the volume of your stored goods should not exceed the pallet. The size of the pallets used in each area of your warehouse should ideally be uniform so as to facilitate management and reduce safety hazards.

How should we configure pallets for our storage racking system?

2. FIFO or LIFO storage ways

The choice of FIFO or LIFO storage is also particularly important when designing pallet racking. If you need to store products with a short shelf life, such as fruits, fresh produce, beverages, then you need to design a FIFO pallet racking system for them to ensure that the products are still intact when sent to customers; if you need to store products with a long shelf life, such as plastics, hardware, electronic components, then you can design a LIFO pallet racking system for them, which can help you maximize the use of warehouse space.

3. Storage environment

Before designing the warehouse racks, the storage environment is also a factor you need to consider. Normal temperature warehouses and cold storage on the racks of the different requirements of frost resistance, indoor and outdoor storage racks on the level of rust resistance requirements are different, so this will lead to their price differences, you need to make a reasonable design plan according to the warehouse environment.

Most of our customers use warehouse storage racks in constant temperature warehouses, but there are still some special industries such as dairy, food, and beverage and pharmaceutical industries that require storage racks in cold storage. Typically, it is more expensive to build racking systems in cold storage because of the higher frost resistance requirements in extreme cold conditions and the much lower installation efficiency because the installer cannot stay in the cold storage for long periods of time, so the installation costs are higher.

How to design cold storage rack?

4. The situation of the stored products

Product factors to consider include the following.

- Number of SKUs

- Whether it needs to be accessible at all times

- Rate of product turnover

- The volume and weight of the product

The number of SKUs is something you need to keep in mind when choosing a pallet rack type. When the number of SKUs is large and the number of pallets per SKU is small, selective pallet racking is the right choice because it allows you to access the goods at any location at any time. When the number of SKUs is small and the number of goods per SKU is large, you can choose high-density racking systems, such as drive-in racks, shuttle racks and push back rack, which will help you to make greater use of warehouse space.

In each warehouse, there are goods with fast turnover and goods with slow turnover. It is up to you to find out whether the products you need to store have a faster or slower turnover rate so that you can better identify which pallet racking type is better for you.

The volume and weight of the product determines the required load capacity of each pallet rack. When doing a warehouse design, we will calculate the thickness of the material used based on the load and size of the pallet racking. The thicker the material, the more expensive the racking will be. We will try to save as much cost as possible for our customers while ensuring safety and avoiding unnecessary waste.

Understanding the product storage process can help you decide which SKUs should be stored close to the shipping and receiving areas, and whether you may need high density storage for some SKUs and more accessible storage for others.

5. Type of Forklift

The type of forklift is also a factor that you need to focus on when designing your pallet rack. Different pallet racking systems use different types of forklifts, so the width of the aisle reserved for the forklift varies in design. counter balance forklifts. generally require a minimum of 3.6 meters of aisle to make turns and U-turns in the aisle, while narrow aisle forklifts require only about 2 meters of aisle to complete the access work, which will allow you to design the pallet racking system with more number of rows.

6. Draw a simple warehouse layout

In most warehouses, the floor is not flat and usually includes some permanent obstacles such as walls and columns. Before proceeding with a formal warehouse racking layout design, it is best for you to measure your warehouse and then draw a simple warehouse layout plan. When you plan to build an efficient warehouse racking storage system, you must design around these obstacles.

You will need to indicate this information in your draft plan.

- The overall dimensions of the warehouse (length, width, height);

- Label the dimensions of the wall columns, their location and the spacing between them;

- Mark the dimensions and location of the fire protection facilities;

- Mark the size and location of each door;

- Marking the location of the access goods;

During the design sketch process, you need to identify potential hazards that could result from the installation of pallet racking, such as limiting access to fire escapes or blocking vents. When you are aware of potential hazards or obstacles, mark them on the warehouse layout sketch so that the racks will not obstruct them.

After you have measured the various obstacles and door locations, make a simple sketch and send it to the racking manufacturer. We will then make CAD layout drawings and renderings for you to confirm that there are no obvious flaws in the pallet racking layout design based on the markings in your sketch to reasonably avoid obstacles.

7. Type of racks

The most important factor in the layout design of warehouse racks is the type of pallet racking. To choose the best racking system for your warehouse, consider the size, shape, weight, storage time and accessibility of your products. For example, most goods are suitable for selective pallet racking, but long goods need to be stored with cantilever racking.

Comparison table of different pallet racking types:

| Type | Space utilization | Storage method | Accessibility | Forklift type | Cost |

| selective pallet rack | 30% | FIFO | higher accessibility | any types forklift | low |

| very narrow aisle rack | 65% | FIFO | higher accessibility | vna forklift/ | lower |

| double deep rack | 42% | FILO | lower accessibility | double reach forklift | lower |

| drive in rack | 70% | FILO | lower accessibility | reach forklift/electric forklift | lower |

| shuttle rack | 80% | FIFO/FILO | lower accessibility | any types forklift | high |

| gravity flow rack | 75% | FIFO | lower accessibility | any types forklift | high |

| push back rack | 60% | FILO | lower accessibility | any types forklift | lower |

| ASRS | 90% | FIFO | higher accessibility | any types forklift | higher |

Pallet racking type Warehouse space utilization Storage method Accessibility Forklift requirements Cost

Please evaluate your storage needs carefully before designing your warehouse racking layout. Different types of racking are suitable for different storage needs, and you need to make a reasonable choice based on your actual storage needs.

8. Your budget

Once you have confirmed the type of racking, the next step you need to consider is the total cost of building the racking system, including the total cost of the racking equipment, transportation, and installation. We recommend that you look for the right racking product for your warehouse layout and storage needs without always aiming for the cheapest price.

Warehouse racking is a product that saves your business money by improving warehouse space utilization and turnover rates. It usually only takes three to five years for the savings you make with warehouse racking to cover the cost of the racking you purchase. With almost all warehouse racking lasting more than ten years and most pallet racking lasting up to twenty years, this is a superb return on investment in the long run and you shouldn’t be sloppy.

And unprofessional warehouse racking suppliers will give you two problems, first, the design and installation is not reasonable. Selective pallet racking, for example, some warehouse racking suppliers to pursue the number of orders in the design will be all for you to use the starter bay design. From a structural point of view, the structure of the starter bay is not as stable as the starter bay plus add-on bay structure. In terms of cost, the starter bay uses more upright frames, so its cost will also be higher. Second, the quality of the racks. There are always some rack manufacturers who use very low prices to attract customers in order to get orders, but then fail to guarantee the quality of the racks. When you search ” rack collapse” on YouTube, you will see a lot of related videos, it is shocking. Racking collapses are usually caused by quality issues or poor design and installation, which can have disastrous consequences for your business.

Of course, to save money, you can also choose to buy used pallet racking, if you can accept it, this is a good way. The most used pallet rack on the market is the teardrop pallet rack. The American Racking Industry Association has unified the standard, so most teardrop pallet racks are adaptable, and if you need to purchase used pallet rack, I suggest you choose this hole type of pallet rack.

9. Seismic activity

If your warehouse is located in an area where earthquakes are frequent, then earthquake resistance is also a factor you need to focus on when designing warehouse racks. Stronger steel can be used to produce warehouse racks, and, by using more screws and connecting rods to connect adjacent racks, the overall stability of the racks can be improved.

As a warehouse racking manufacturer with nearly twenty years of experience, Mracking’s warehouse racks have passed a series of seismic tests. In terms of stability, we use accessories such as span beams, wire mesh decking, connecting rods and access beams to improve the stability of the racking system and ensure the safety of the racking system.

10. Safety of the racking system

People are the main body of the warehouse work, the most important point of the racking layout design of the warehouse racks is to ensure the personal safety of warehouse workers. We need to fully consider the possible safety hazards when designing the layout of the warehouse racks and try to avoid it through a reasonable design.

The rack aisle width needs to be set reasonably according to the type of forklift to avoid the waste of storage space caused by the wide channel or the situation that the narrow channel can not run normally. The width of the channel should be greater than the width of the forklift, and the safety operation space of one meter is generally designed to prevent the rack deformation or even collapse caused by the impact of the forklift truck on the rack.

The carrying capacity of the rack needs to be measured according to the actual weight of the stored goods. Taking selective pallet rack as an example, generally two pallets are placed on each layer, so the loading capacity of the pallet rack must exceed the actual weight of two pallets of goods when it is designed. Remember, it is forbidden to overload, which is necessary to ensure the safety of the racking system.

In the warehouse racking system to do a good job in the fire design is also extremely important to ensure the safety of the racking system. If you store products belonging to flammable and explosive products, then I suggest you do not choose plywood panel, as far as possible to use steel or wire mesh decking instead of plywood. At the same time, when designing the layout of the racks, pay attention to the location of the fire hydrant and design enough space for the fire hydrant to prevent the racks from blocking the hydrant and thus affecting the use of the hydrant.

When designing the layout of the pallet racking, the location of the safety exits should also be left, so that the normal passage of the safety exits cannot be obstructed under any circumstances.

How To Make The Right Warehouse Racking Layout Design?

How do the correct warehouse racking layout design, let me make a simple summary for you

1. Accurately measure the dimensions of the warehouse.

Accurately measure the dimensions of your warehouse, including the length, width, height and the location of obstacles in the warehouse, and draw this information into a sketch, which will help us greatly when making accurate drawings later.

2. Determine your storage needs.

You will need to go into detail about your product, such as how much cargo to store per pallet, whether you need FIFO storage, etc. When your storage needs are clear enough, it will become easier to choose the type of racking system.

3. Choose the right racking system.

You need to choose the most suitable warehouse racking system according to your storage needs, warehouse environment and your budget situation. Mracking, as a leading warehouse racking manufacturer in China, can provide the following types of racking systems for you to choose from

- Selective pallet racking

- Double-deep pallet racking

- Narrow aisle pallet racking

- Drive-in pallet racking system

- Shuttle pallet racking system

- Gravity pallet racking system

- Push back racking system

- Automated storage and retrieval system (ASRS)

- Cantilever racking system

- Warehouse mezzanine

- Boltless rack

- Stacking rack

- Carton flow rack

4. Send sketches to the racking manufacturer and discuss your storage needs with them.

Send your sketches and your storage needs to the racking manufacturer and they will create a professional floor plan and 3D rendering based on the information you provide for your confirmation.

5. Order and install the racking system.

Order the warehouse racking and you can choose to have the racking manufacturer help you arrange shipping to the port in your country.

The last step is racking installation. In order to achieve the desired effect of the expected design, you need to strictly follow the layout in the drawing for the racking installation.

Full service support from Mracking Company

Designing a reasonable warehouse racking layout while making full use of the warehouse space is a serious challenge for you. We always believe that professional things should be left to professional people. Mracking has been engaged in warehouse racking and mezzanine design for nearly twenty years and has a team of more than five experienced engineers who can ensure the completion of any pallet racking layout design related work. If you need to visit our project cases, please send an email to bradley@chinastoragerack.com with the subject “Pallet Racking Project Case Reference” and a complete project case will be sent to you for your reference. If you need other support on warehouse storage, please contact Mracking now!