1. Introduction

Modern warehouse designs consist of catering safety and maximizing efficiency for businesses and their workers. When a warehouse is well-planned, it has a layout that streamlines operations, and the risk of accidents is also reduced. If you are looking for different methods of improving the warehouse design and how it adds efficiency and safety to your premises, the guide below can be helpful.

2. Key Elements of Modern Warehouse Design

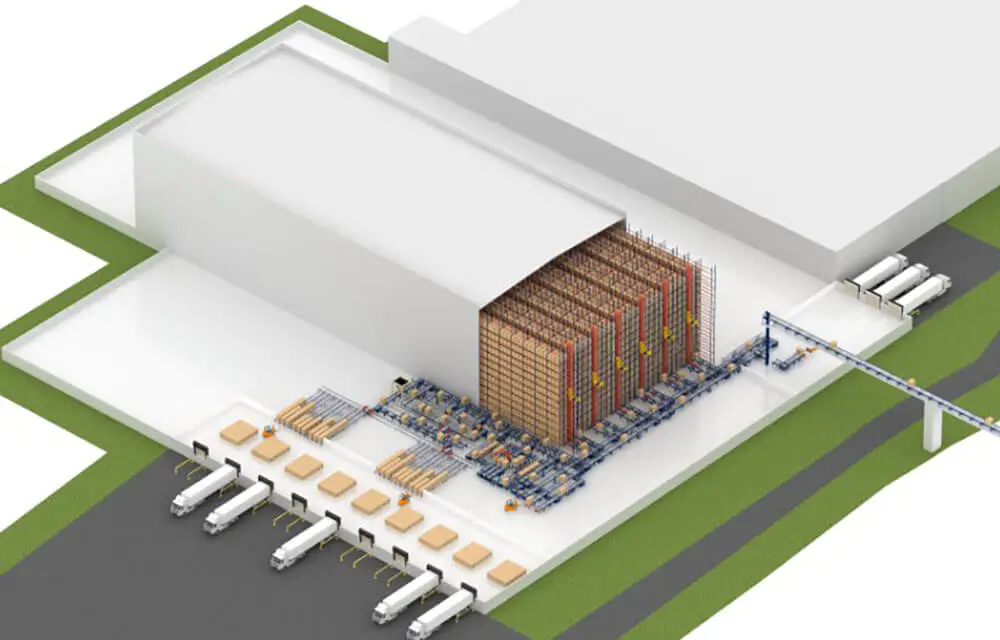

A modern racking system adds efficiency to the warehouse. Modern warehousing consists of drive-in racks, pallet racks, and cantilever racks, which are very important for appropriate storage and organization which ensures durability and safety. Some key elements of modern warehouse design comprise the following:

Optimizing the Vertical Space in the Warehouse

The use of racking is quite suitable for a modern warehouse but to optimize the vertical space in the best possible way, using decking and mezzanine also helps. The mezzanines are floors that are added to the warehouse to create additional space for storage without floor expansion.

Similarly, when it comes to decking, the racking and mezzanine are enhanced with the help of it as it offers stable platforms where goods can be stored. The use of vertical spaces in a strategic way offers to utilize the vertical space in an effective way which multiplies the area usability in the same warehouse. It allows for high storage and efficiency in operations.

Improved Efficiency and Safety

The addition of mezzanine and pallet racking systems not only optimizes the space for storage but also ensures a safe working environment. When racking systems are integrated properly, the risk of collapses is reduced because they help prevent the overloading of shelves.

The installation of decking and mezzanines also ensures that spaces are clutter-free and ensures an organized warehouse. When a warehouse has these aspects implemented, a balance between storage capacity and workflow is achieved which ensures the safety of workers as well as the products in the warehouse.

3. The Role of Racking Systems in Modern Warehouse Design

Racking systems play a vital role in warehouse efficiency and they help utilize the space very well. These systems help organize inventory in a way that maximizes accessibility as well as capacity.

Types of Racking Systems

There are different types of racking systems that can be crucial for a modern warehouse design and every type has its benefits to offer. Let’s take a look at the subtle racking opinions.

- Pallet Racking: It is one of the most common types of racking which is versatile and suits different load requirements. It is easy to access the pallets and the inventory management is enhanced with the help of pallet racking.

- Cantilever Racking: Cantilever racking is suitable for products that are bulky and have longer lengths like steel bars and pipes. This racking system has access from the front and handles these products in an efficient way.

- Drive-In/Drive-Through Racking: The drive-in and drive-through racking system is usually opted for high-density storage where the pallets are placed in depth. The drive-in racking system allows for forklifts to access the racking system from one side and retrieve the products. Drive-through racking allows access from both sides and improves the storage density being suitable for bulk goods.

3.1. Maximizing Vertical Space with Advanced Racking

The advanced racking systems allow for maximizing the vertical space, and some of its benefits comprise the following:

- Vertical racking systems ensure that modern small warehouse design has been very sufficiently utilized to enhance the storage capacity. It makes the most of using the height of the warehouse rather than the flooring.

- Vertical space maximization allows businesses to avoid the cost of warehouse expansion and they can easily make the use of space up to the ceiling if they plan the racking systems efficiently.

- Vertical racking systems offer enhanced organization of inventory and the items can easily be grouped into vertical columns which helps enhance workflow efficiency.

- These vertical racking systems are scalable and hence the height can be adjusted and more levels can be added when the business demands a growth in inventory.

Some of the examples of vertical racking systems for an organized strategy of warehouse comprise the following:

High Bay Racking

High bay racking allows the racking of the warehouse to go up to the high ceilings. The system of high bay racking can go up to 40 meters in height, can store large quantities of goods and consumes less floor space.

Narrow Aisle Racking

Narrow aisle racking systems have compact widths and more rows for racking in the given area. These aisles can be accessed through forklifts which are meant to work well in less space and also ensure stacking of items vertically.

3.2. Adjustable and Modular Racking for Flexibility

Adjustable and modular racking systems are equipped with flexibility and hence offer suitability for modern warehousing due to their adaptability to changing storage requirements. Adjustable racking systems can be modified in terms of shelf heights, allow adding and removing levels, and accommodate the different sizes of products. Industries with fluctuating products and their demands may benefit from such a system of racking.

Modular racking offers flexibility and allows for straightforward reconfiguration and scaling. This system can be adjusted and expanded without much distortion and can easily accommodate inventory changes. It is capable of being rearranged and expanded and hence offers to maintain the warehouse operations optimally.

4. Enhancing Efficiency Through Strategic Warehouse Layouts

Placement of the racking in a strategic way plays a vital role in improving the workflow efficiency in a warehouse. When the layout of the warehouse has been carefully planned productivity and efficiency both increase ensuring smooth operations.

Some of the tips for designing an efficient warehouse layout comprise the following:

- Analyze the workflow that has to be undertaken in the warehouse, prioritize the items that are in high demand and map them to be closer to the shipping area.

- Arrange the overall ranking system in a way that facilitates smooth movement and groups identical products together.

- You can also implement an automated warehouse management system which also helps to streamline the process of picking and handling.

- You can implement modular racking so that the racks can be reconfigured when there’s a change in storage need.

4.1. Mezzanines: Expanding Usable Space

Integration of mezzanines is a suitable approach to make use of space in the warehouse without increasing the floor space. Mezzanines allow to add more levels for storage and offer a very cost-effective solution.

However, the safety considerations must be kept aligned and ensure that there is a verification of the load-bearing capacity and that fire safety regulations are adhered to. Also, ensure that safety features are incorporated with appropriate access to the storage areas.

4.2. Decking Solutions: Secure and Versatile Storage

Decking solutions improve the security and versatility of the modern system of racking as they have the ability to suit different storage needs. There are different types of deckings like wire mesh, steel, wood, etc and they have different applications too.

Wire mesh decking for instance is opted in applications requiring ventilation and visibility, whereas the wooden one offers a surface for general storage. Steel decking is suitable for handling heavy loads protecting the goods from falling. Hence the versatility of decking systems makes them suitable for storing all types of goods keeping safety as a prime concern.

5. Safety Enhancements in Modern Warehouse Design

Modern warehouse designs keep the safety of workers and inventory as one of its prime concerns. Hence, while designing a modern warehouse aspects like emergency exit, adequate lighting, and fire fighting systems are important to consider. Apart from that the structural integrity of the warehouse as well as racking systems also play a significant role in safety of the warehouse.

Racking systems that are designed appropriately ensure that accidents and injuries are prevented and overall safety of the warehouse is increased. The racking systems consist of features like barriers, load signs and labeling so that accessing them becomes easy and also they ensure that the risk of falls and injuries is prevented.

5.1. Racking Safety Features: Guardrails, Backstops, and More

An effective racking system will incorporate several safety features so that accidents can be prevented and a safe working environment can be ensured. Guardrails, safety netting, and backstops are ensured to be in place.

Guardrails help to prevent the workers from falling when on high and elevated areas, safety nets catch the falling items protecting from product damage and backstops prevent pallets from tipping over.

Apart from safety features, timely inspection and maintenance are also very important. Routine checks must be made to ensure that racking systems are in good condition and meeting the safety standards. Moreover, the features incorporated like netting and guardrails are functioning properly, in case they are not prompt action but can be taken to resolve these issues.

5.2. Lighting and Visibility: Improving Safety Around Racking

Proper lighting is also crucial for improving the visibility in the warehouse and reducing the risk of accidents. When the warehouses are well-lit, the employees can easily navigate and access the aisles. Some of the tips for lighting and visibility in the warehouse may include:

- Install bright and even lighting so that shadows are eliminated, and all the areas of the warehouse are illuminated perfectly.

- The aisles and high storage areas must be well-lit so that accessing them and retrieving items is safe.

- Implement smart lighting systems like ones with motion sensors in areas that are frequently used so that they help save energy and also ensure light in the space as soon as someone comes around.

- Choosing lighting fixtures that don’t use harsh reflections also helps in reducing glare to ensure improved visibility.

6. Integrating Technology with Modern Racking Systems

The role played by technology in modern warehouse design cannot be ignored as it transforms the warehouse into a very efficient one with appropriate safety and inventory management in place. Some of the technology features to be integrated are given below:

- Sensors can be integrated into the racking systems which help in monitoring the temperature, humidity and load to ensure that optimal storage conditions are achieved. It helps to keep the racks away from overloading and also helps reduce the chance of damage.

- Adding automation in the racking systems helps to streamline processes like sorting and picking, these days robots and conveyor belts are also added in the warehouse to help the racking improve in terms of accuracy and efficiency.

- The smart racking systems also offer enhanced inventory management as it offers tracking the inventory in real-time. It allows for improved forecasting and also signals about the overstocking and understocking timely.

7. Designing for Future Growth and Adaptability

Warehouse designs should be created keeping in mind the future scalability and growth so that when the storage needs change the warehouse can easily accommodate them without any significant expansions. Modular and scalable racking systems play a vital role in this case as they offer high flexibility and hence easy adjustments can be made when the demand for storage increases.

8. Conclusion

The modern industrial warehouse design must be based on two aspects as its prime consideration; efficiency and safety. You can choose advanced racking systems, decking, and even a mezzanine to make the most of your warehouse space.

Mracking offers the finest quality racking systems, which enhance the operational efficiency of your warehouse as they are customized based on your requirements.